Patents

Literature

176results about How to "Real-time temperature control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

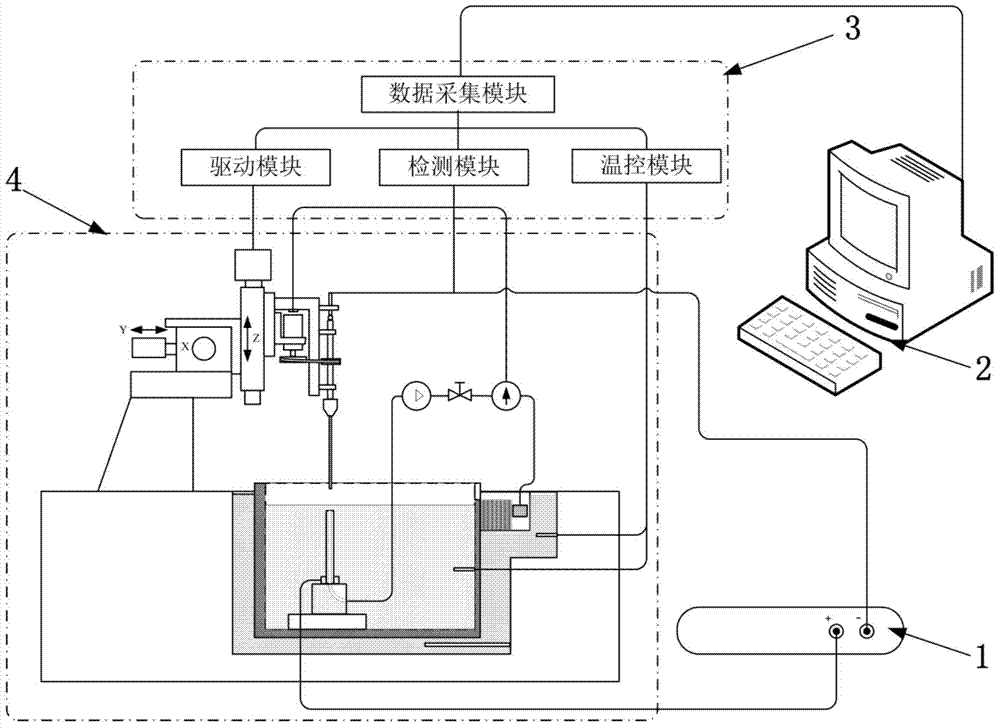

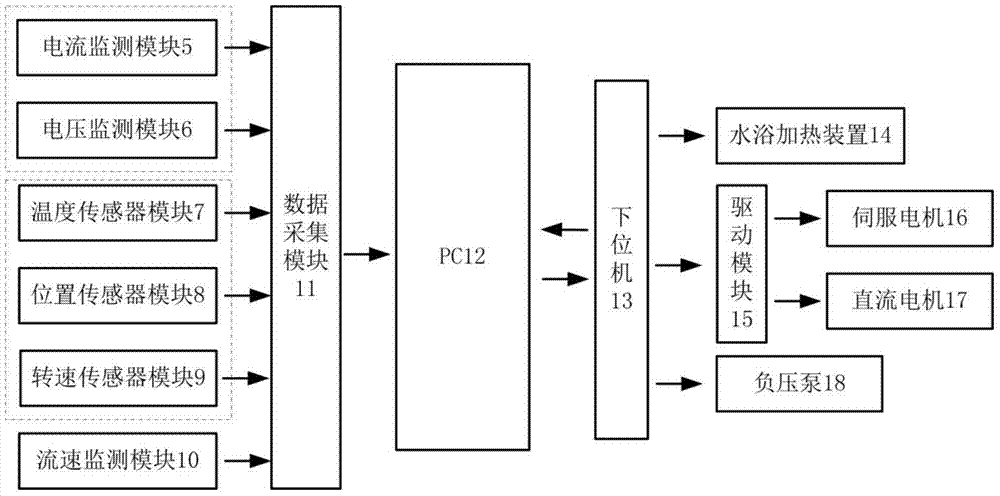

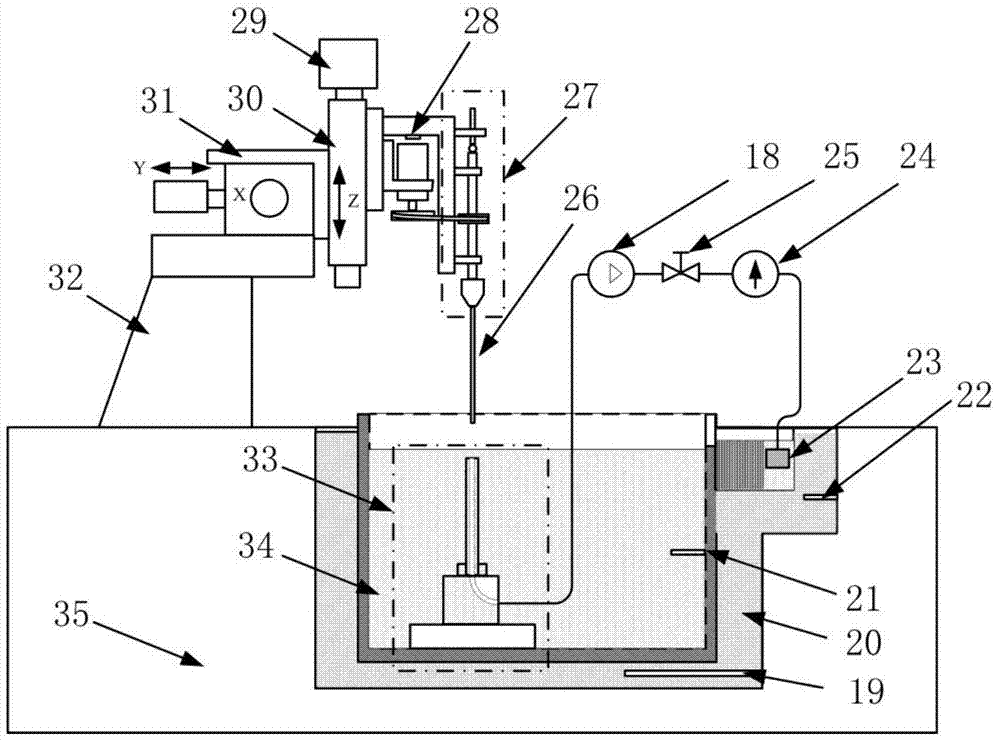

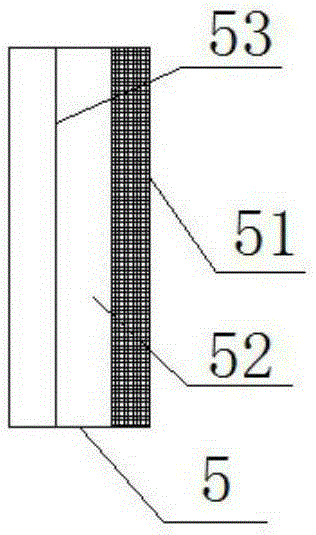

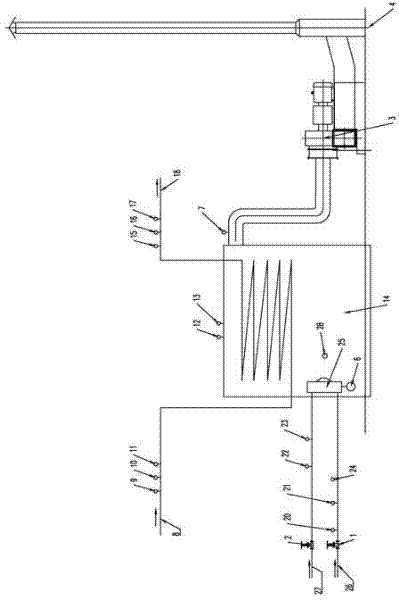

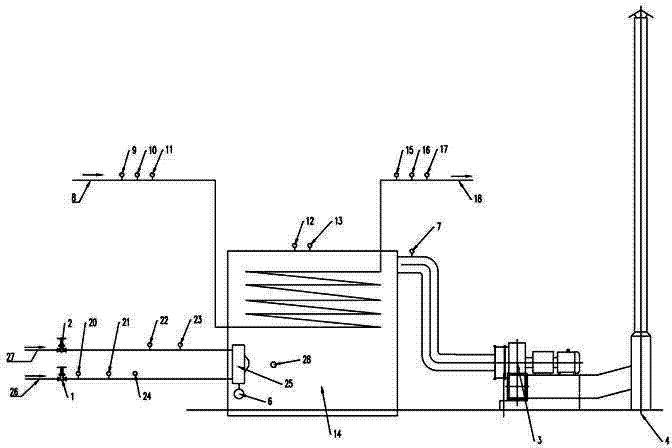

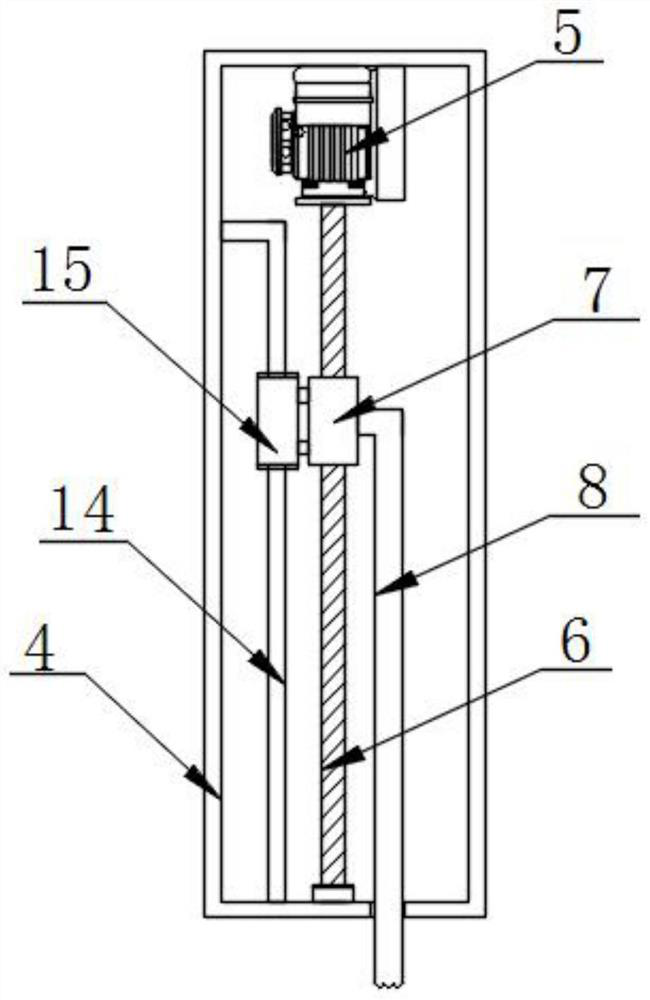

Electrochemical polishing device for inner surface of long and thin pipeline

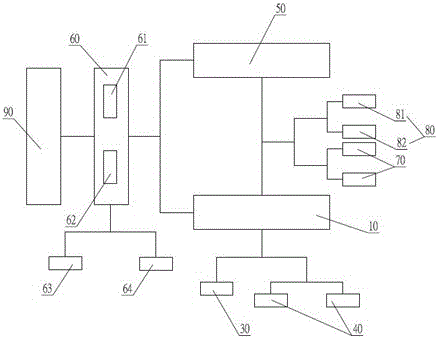

The invention provides an electrochemical polishing device for the inner surface of a long and thin pipeline and belongs to the field of precise non-traditional machining. The structure of the electrochemical polishing device comprises a control terminal module, a power supply system, a monitoring module and a processing main body, wherein the control terminal module has a function of displaying each current environmental parameter of the device; a monitoring system comprises the monitoring module for monitoring each environmental parameter. The electrochemical polishing device disclosed by the invention adopts a tool electrode with a spiral slot structure; during polishing, the tool electrode performs axial linear reciprocating movement and rotary motion to realize full controllable perturbation of a fluid inside the pipeline and take away air bubbles and processing precipitates generated during processing, so that electrolytic reaction on the inner surface of the long and thin pipeline is performed uniformly; a vacuum pump is used for sucking out electrolyte from the bottom end of the pipeline so as to prevent ejection of the electrolyte during processing; the electrolyte is fully purified by an electrolyte circulating filtration system, so the service life of the electrolyte is prolonged; the temperature of the electrolyte can be regulated and controlled in real time by an electrolyte heating system, so that the polishing effect is improved.

Owner:DALIAN UNIV OF TECH

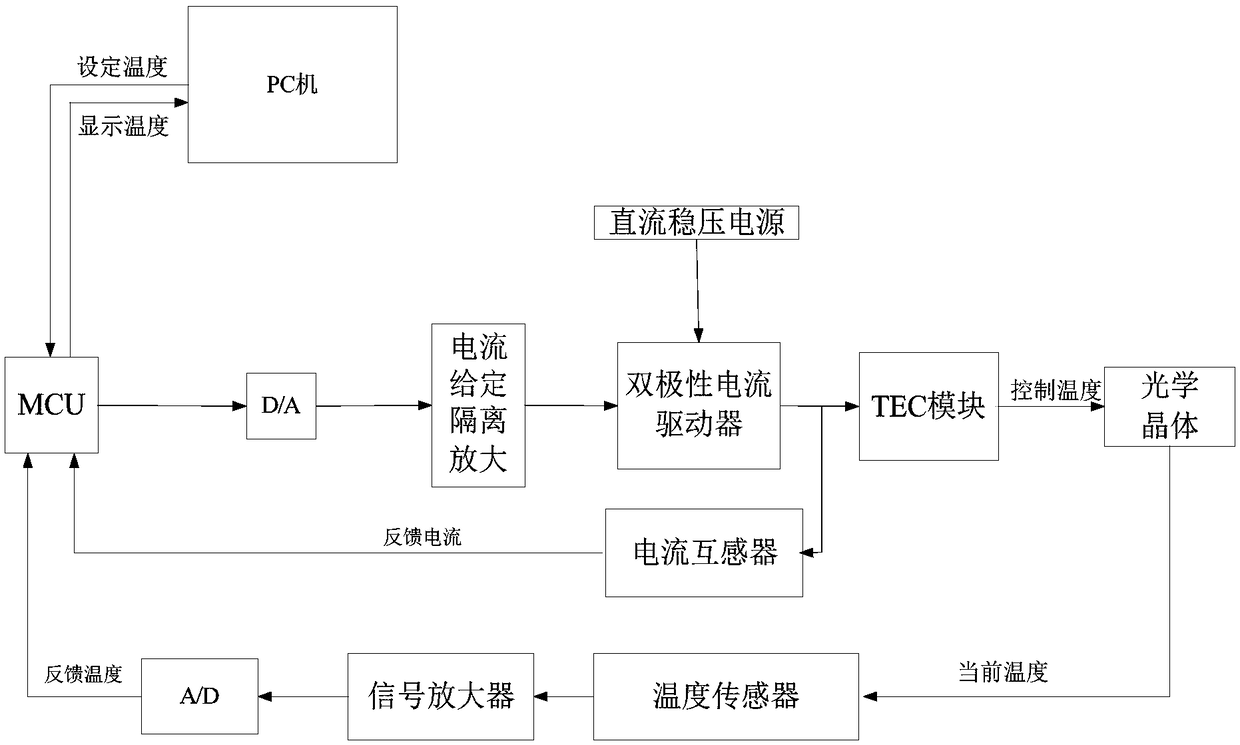

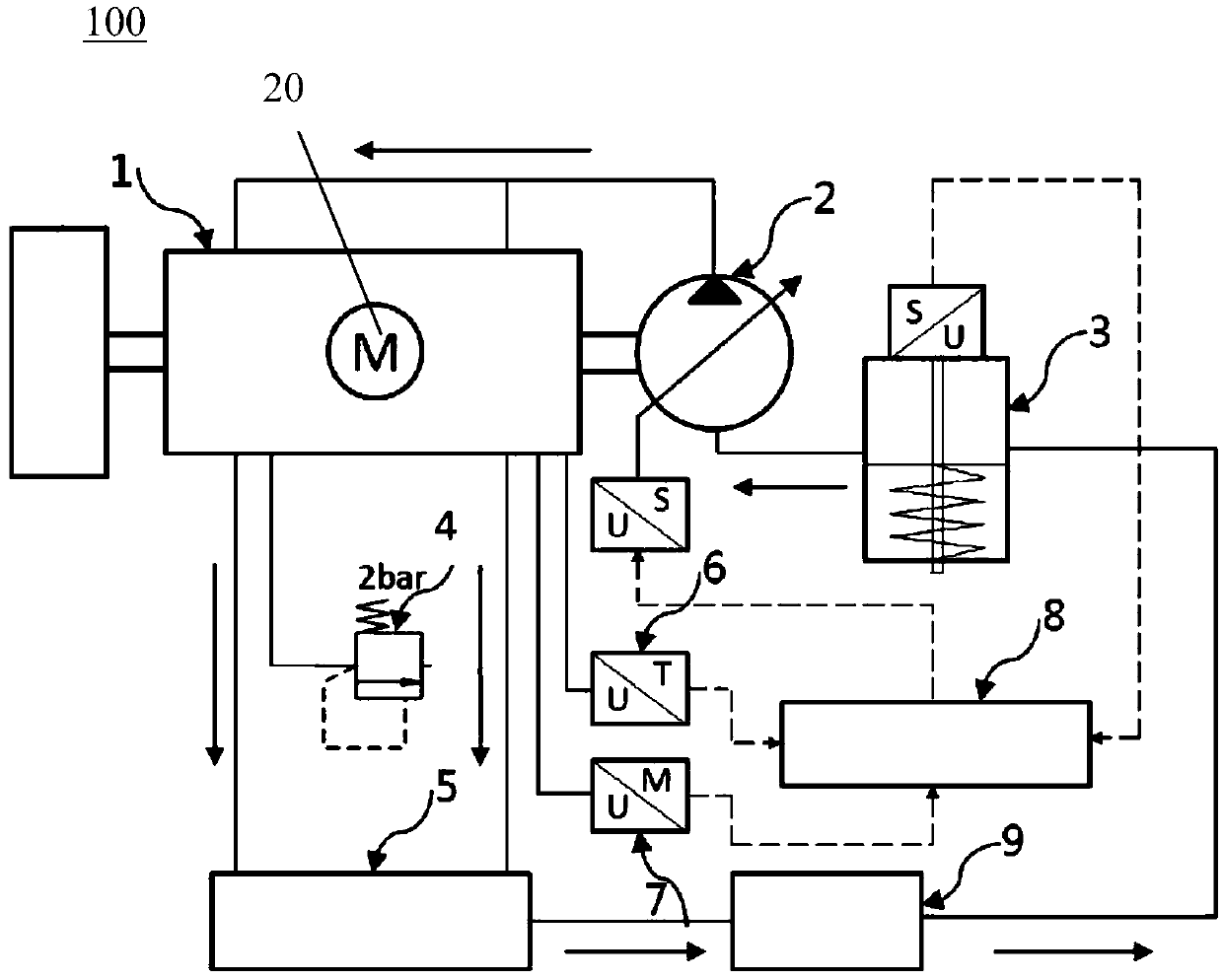

Power stable solid laser and control method

PendingCN108666856AAvoid hysteresisAvoid errorsLaser detailsTemperatue controlLoop controlHeat conducting

The invention discloses a power stable solid laser and a control method thereof. The power stable solid laser comprises a base inside which cooling water flows, a heat-conducting carrier for mountingand fixing an optical crystal of the solid laser, a temperature sensor disposed on the heat-conducting carrier, a semiconductor refrigeration unit disposed between the heat-conducting carrier and thebase and driven by a bipolar current driver, and a control unit. A temperature-current double closed-loop control system is realized on the basis of the conventional temperature control system; an inner loop is a closed current loop controlled by PI, and an outer loop is a closed temperature loop controlled by PID, so as to improve the control precision of the system, and finally achieve the purpose of improving the power stability of the solid laser.

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

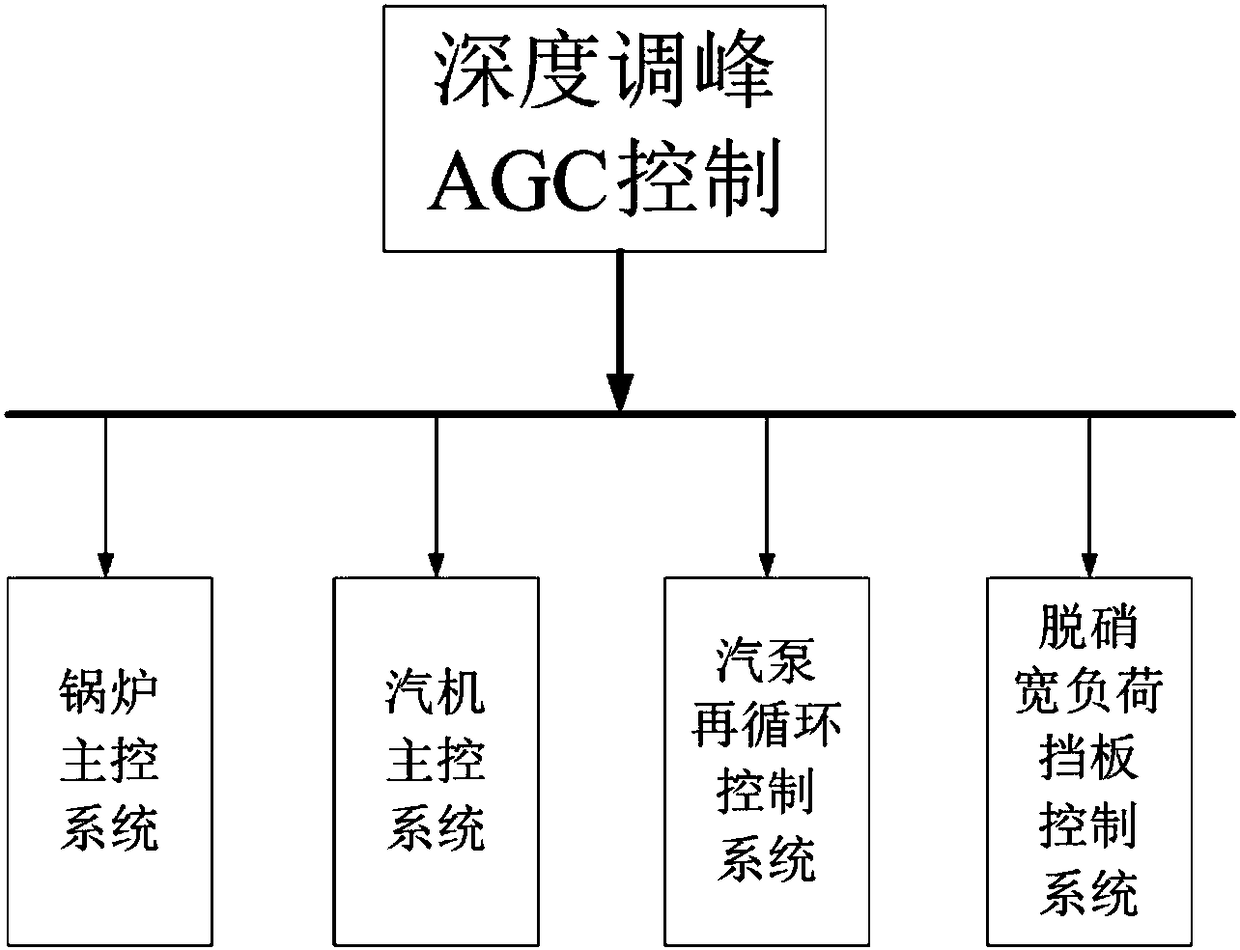

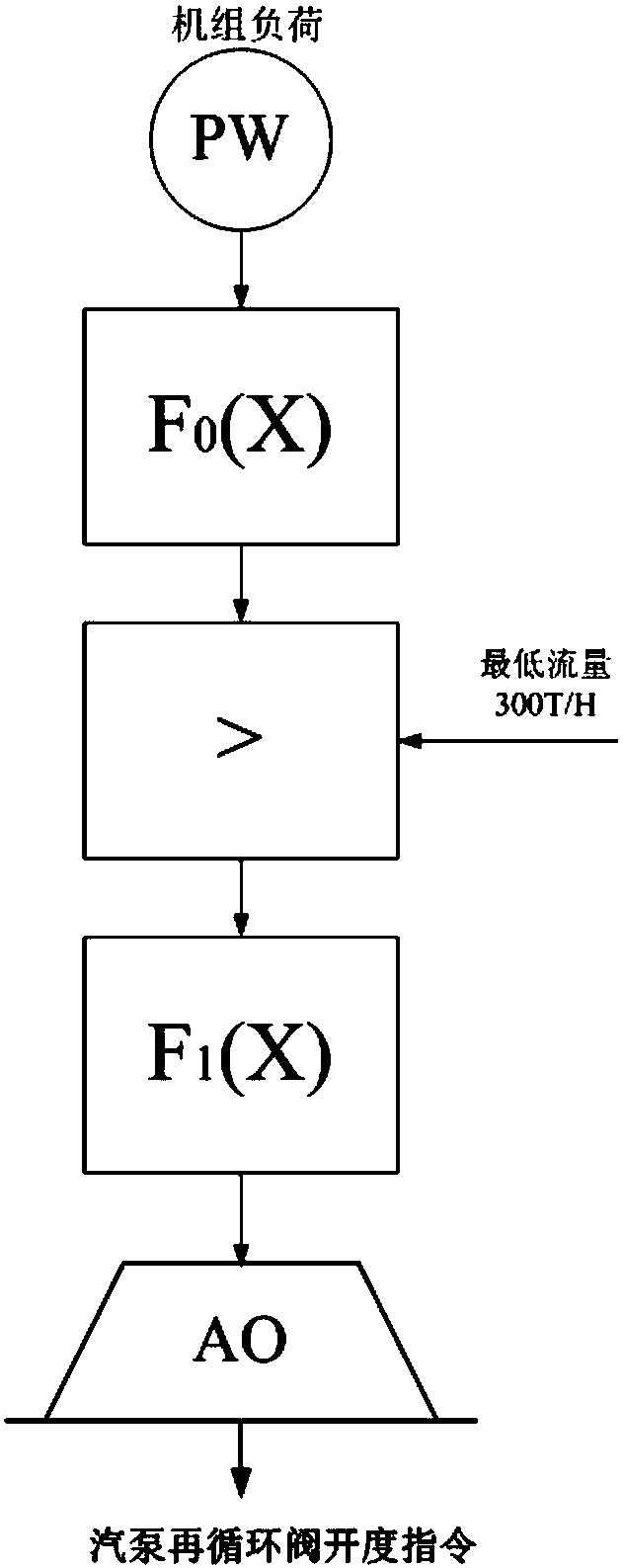

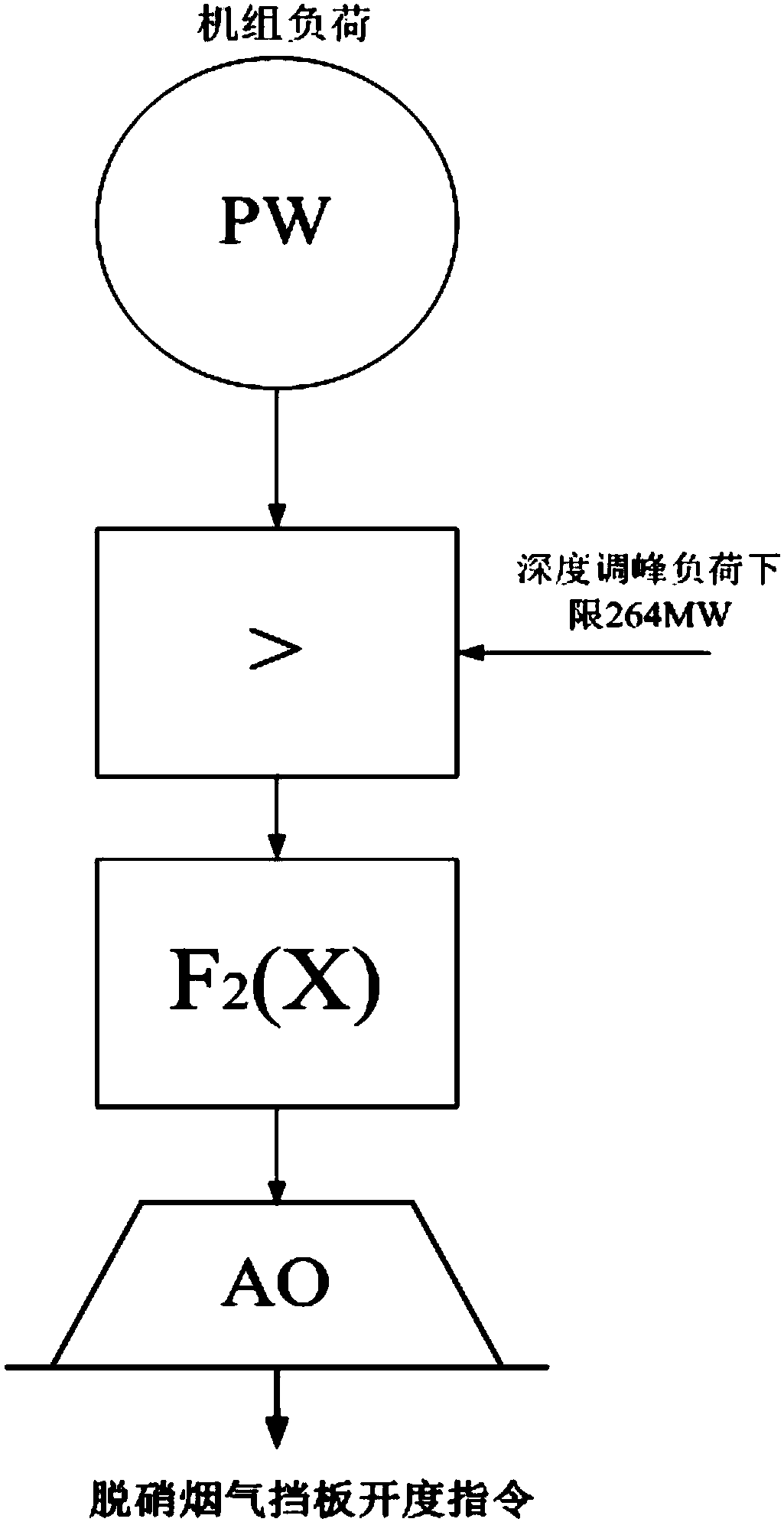

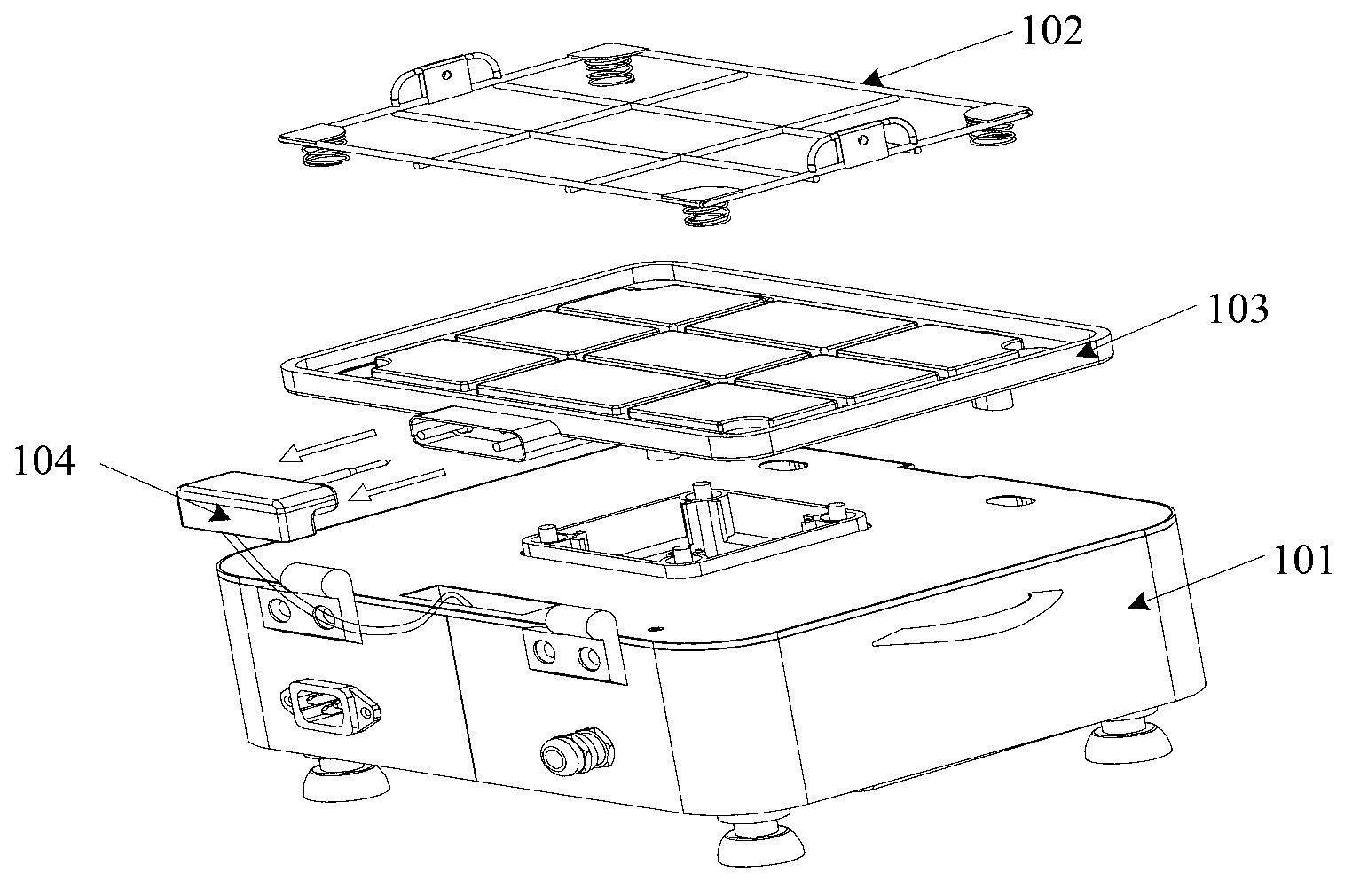

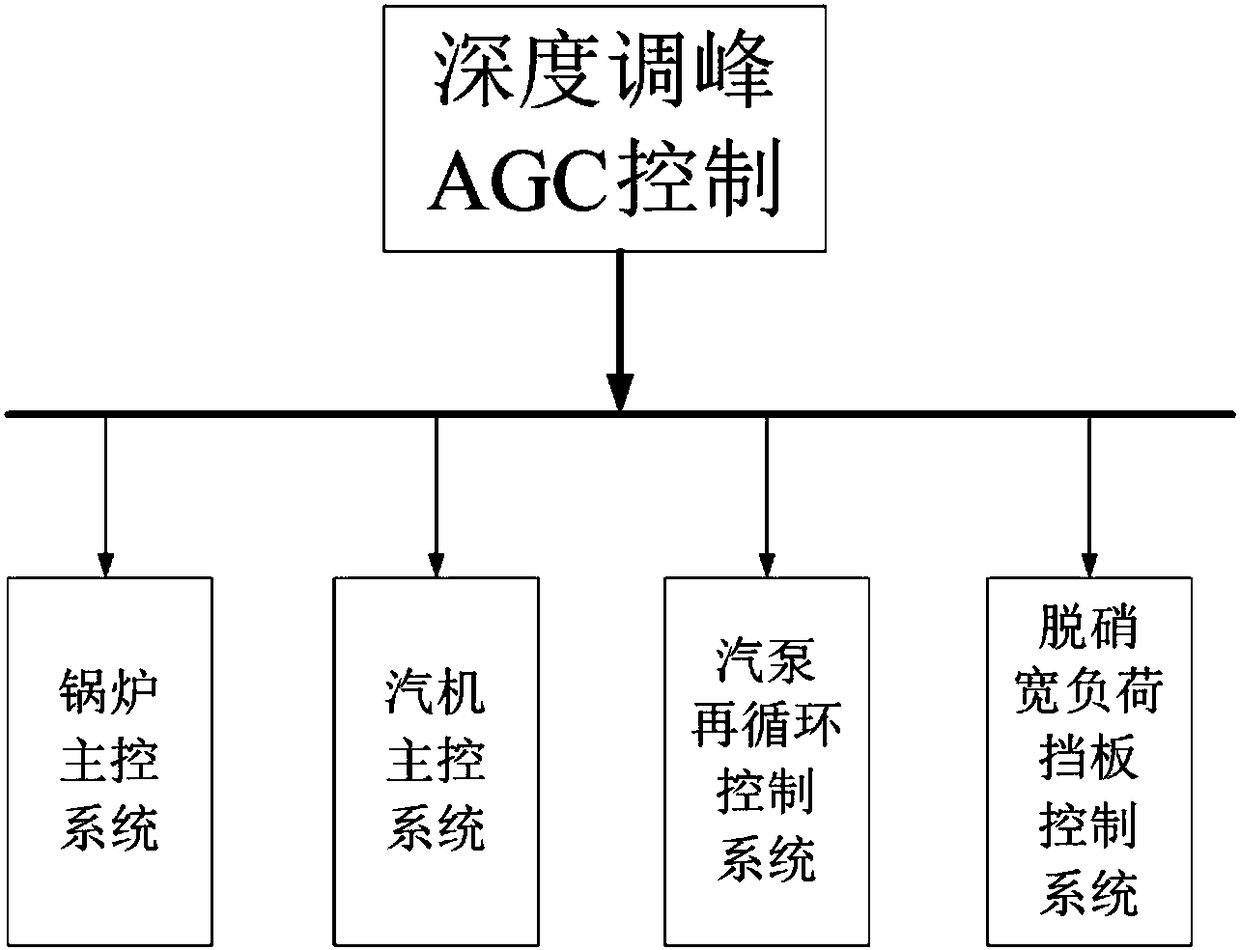

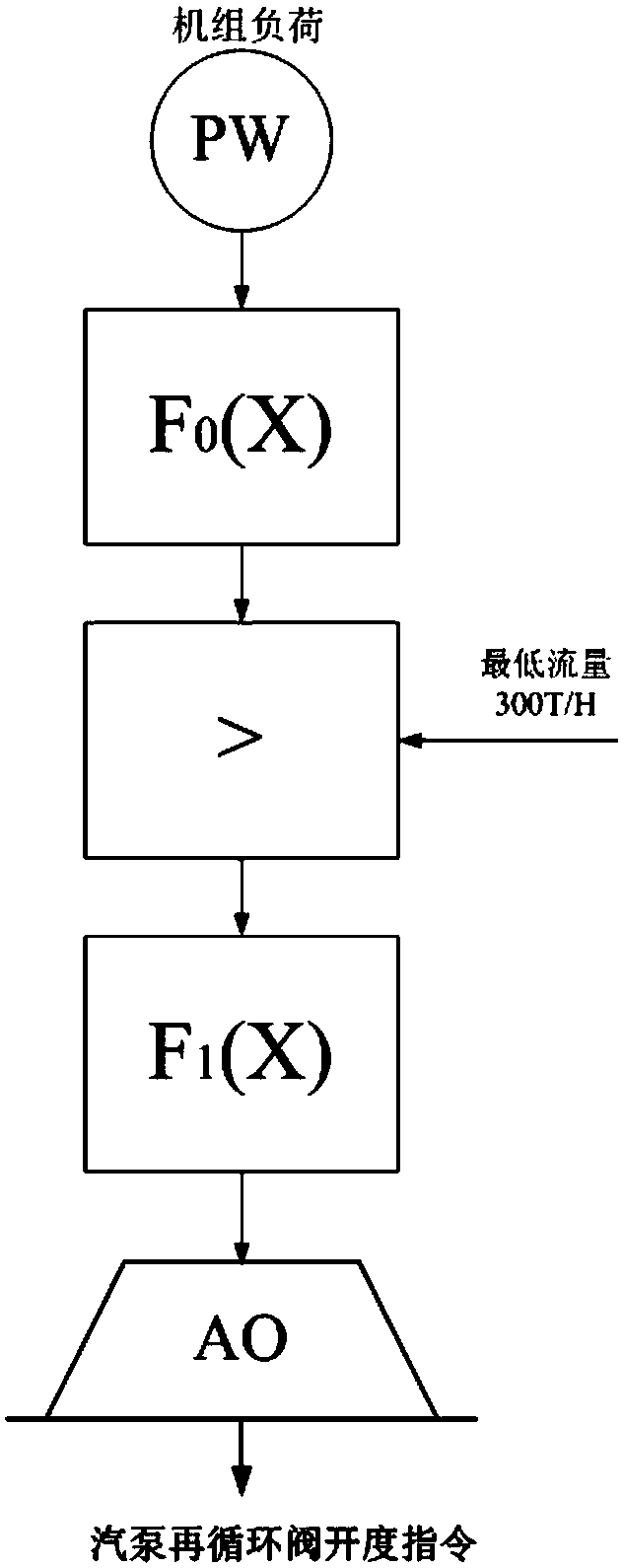

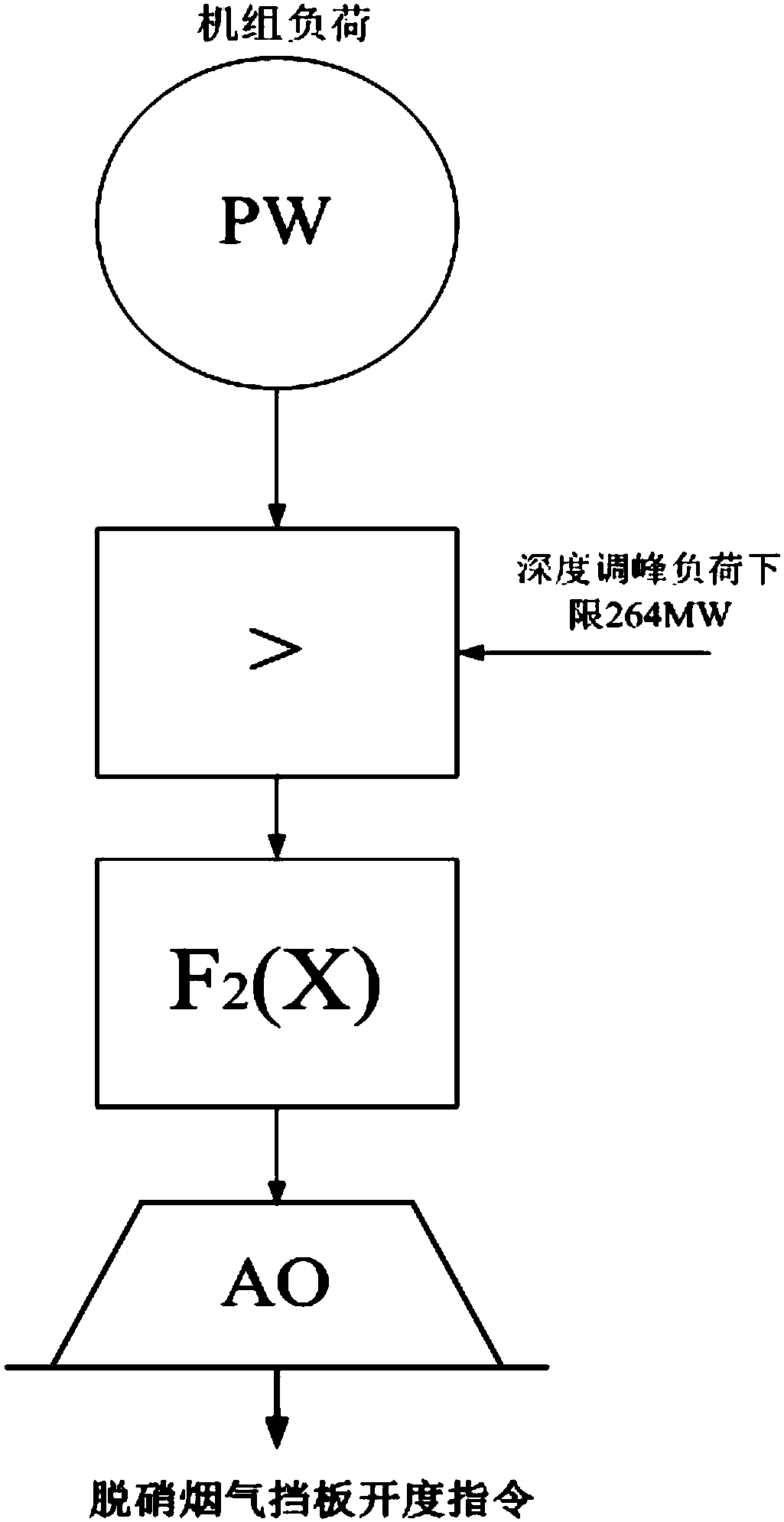

AGC control system for 660MW supercritical unit under deep peak regulation

ActiveCN108490794AIncrease adjustment depthAvoid cavitationAdaptive controlAutomatic controlParameter control

The invention discloses an AGC control system for a 660MW supercritical unit under deep peak regulation, belonging to the technical field of AGC control. When the load of the unit is in a deep peak regulation interval, minimum flow limitation is carried out on the flow of a gas pump; when the flow of a single gas pump is smaller than 425T / H, and a re-circulating valve of the gas pump is involved in gas pump inlet flow regulation, is slowly started and is maintained to work over a minimum output; meanwhile, the smoke temperature is increased at a boiler side, and a denitration wide load baffleis slowly turned down along the load of the unit so as to maintain the smoke temperature of the unit under a low load; and when the load of the unit is in a deep peak regulation interval, AGC speed isautomatically reduced through judgment, meanwhile, PID self-adaption and variable parameter control of boiler main control and steam engine main control can be realized through AGC, so that the automatic control quality is improved. According to the AGC control system, the following of the re-circulating valve and the denitration wide load baffle of a steam feed pump along the automatic load control of the unit, the AGC automatic control under deep peak regulation, the steam engine main control PID self-adaption control and the boiler main control PID self-adaption control can be realized.

Owner:MAANSHAN DANGTU POWER GENERATION

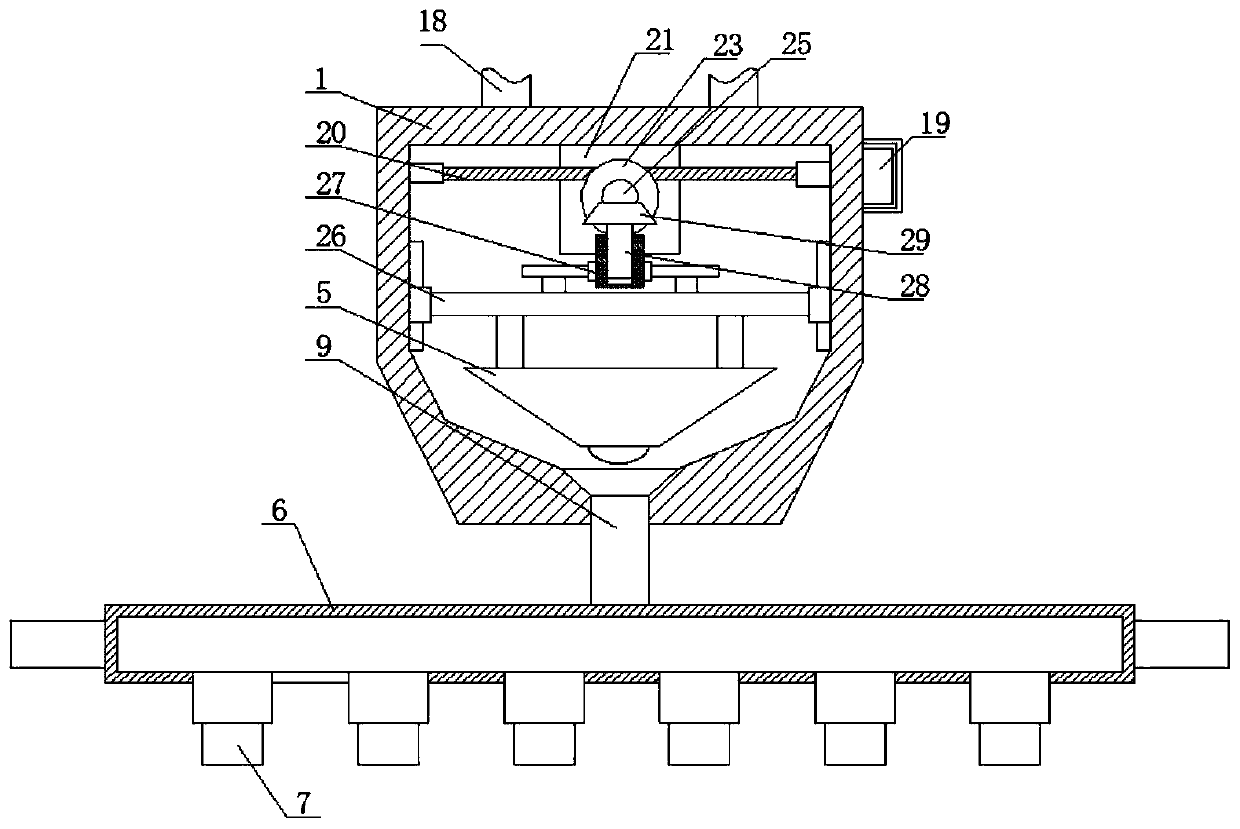

Frying and roasting machine

ActiveCN103284620AImprove qualityReduce the risk of adverse or harmful healthRoasters/grillsFrying pansEngineering

The invention discloses a frying and roasting machine. The frying and roasting machine uses a first sensor assembly and a second sensor assembly to measure temperature of fried and roasted food and temperature of a first heating plate respectively and transmits the temperature to a controller. The controller processes data according to the current temperature of the fried and roasted food and the current temperature of the first heating plate so as to control the temperature of the first heating plate in real time and control maturity degree of the fried and roasted food. The frying and roasting machine can adjust the temperature in frying and roasting in real time according to real conditions, obtain fried and roasted food with higher quality, conform to relevant regulations of food machining better and lower adverse risks or risks in damaging health.

Owner:MINGLE DEV (SHENZHEN) CO LTD

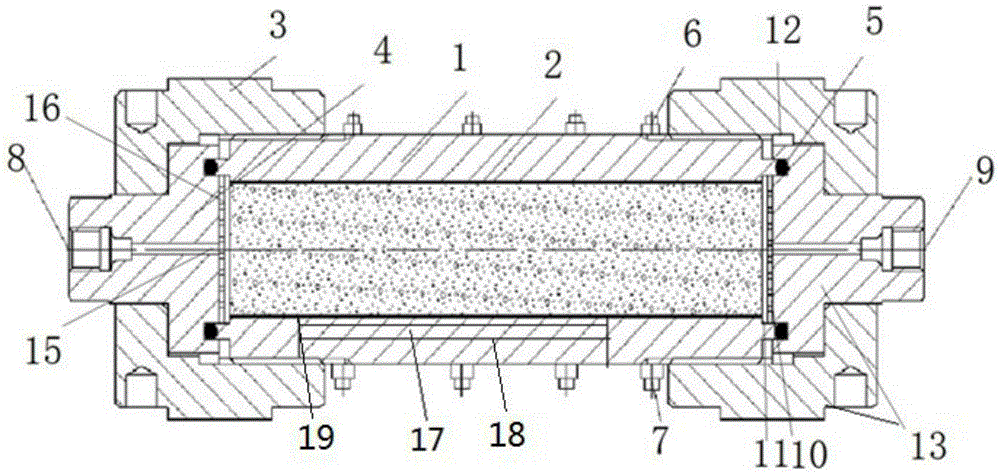

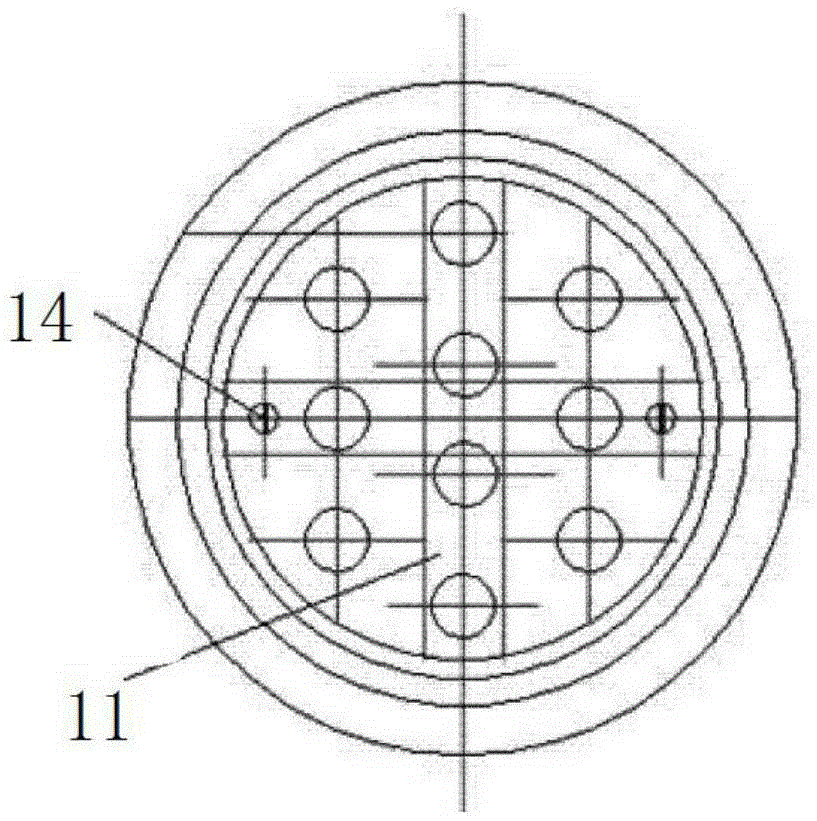

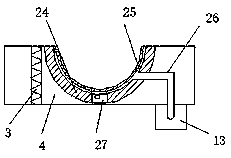

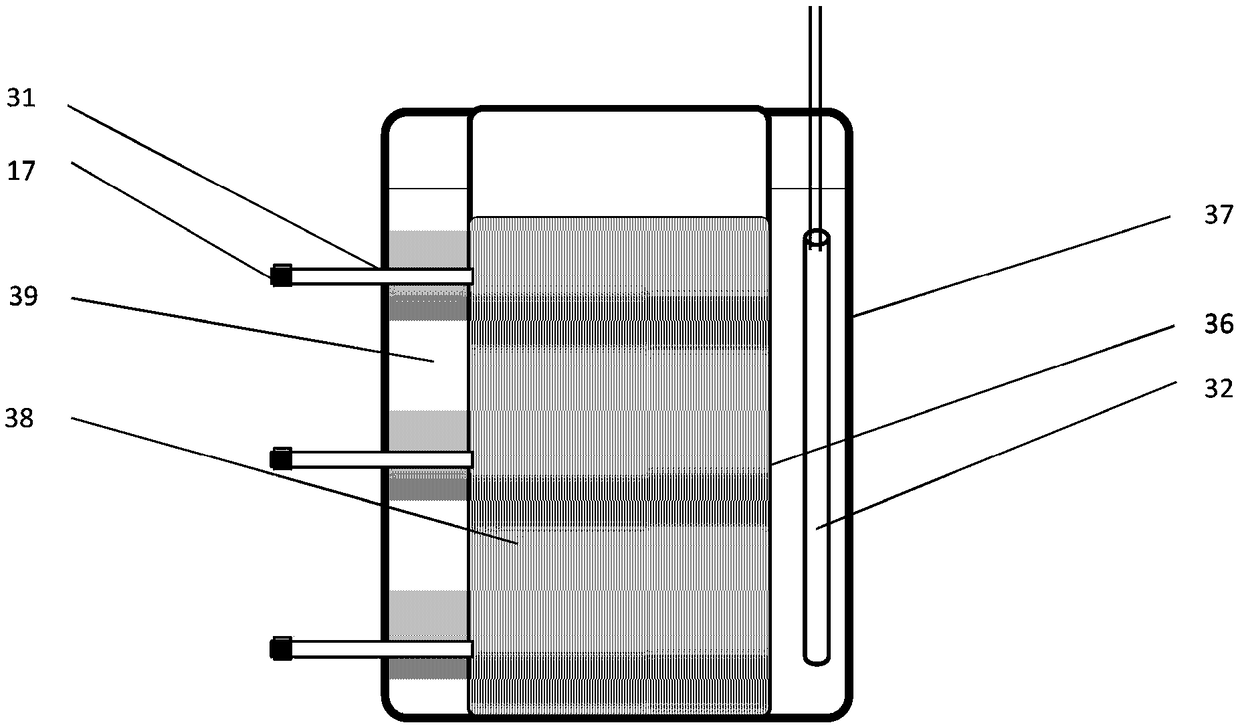

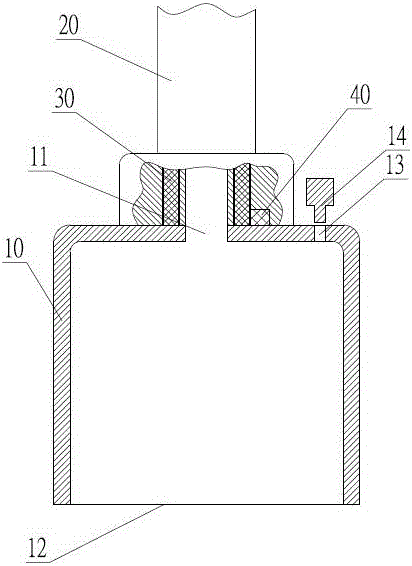

Sand filling model pipe

InactiveCN105239978APrevent flow phenomenonGuaranteed sealing performanceFluid removalEngineeringDouble ring

The invention provides a sand filling model pipe. The sand filling model pipe comprises a main body, plugs, pressing caps, an inlet and an outlet, wherein the main body is a hollow pipe, and is provided with a sampling port and a pressure measuring port; the plugs are positioned at the two ends of the main body, and are connected with the main body through screws; the pressing caps are fixedly connected with the plugs; the inlet and the outlet are positioned at the two ends of the sand filling model pipe; the inner wall of the main body is uniform and consistent in roughness, and is an electrospark roughened inner wall; the roughness of the inner wall of the main body is greater than Ra12.5; the plugs are double-ring sealing plugs; and a temperature sensing heating device is arranged in a shell of the main body, and is fixedly connected with the main body. The sand filling model pipe can effectively prevent the streaming phenomenon between sand particles and the inner wall in the experimental process, so that the precision of experimental results is guaranteed, and the tightness is good; and the sand filling model pipe is provided with the temperature sensing heating device, so that the cleaning is facilitated, and the accuracy of experimental conditions can be guaranteed.

Owner:南通市飞宇石油科技开发有限公司

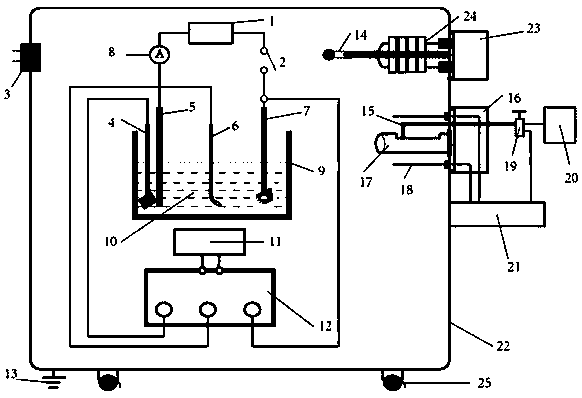

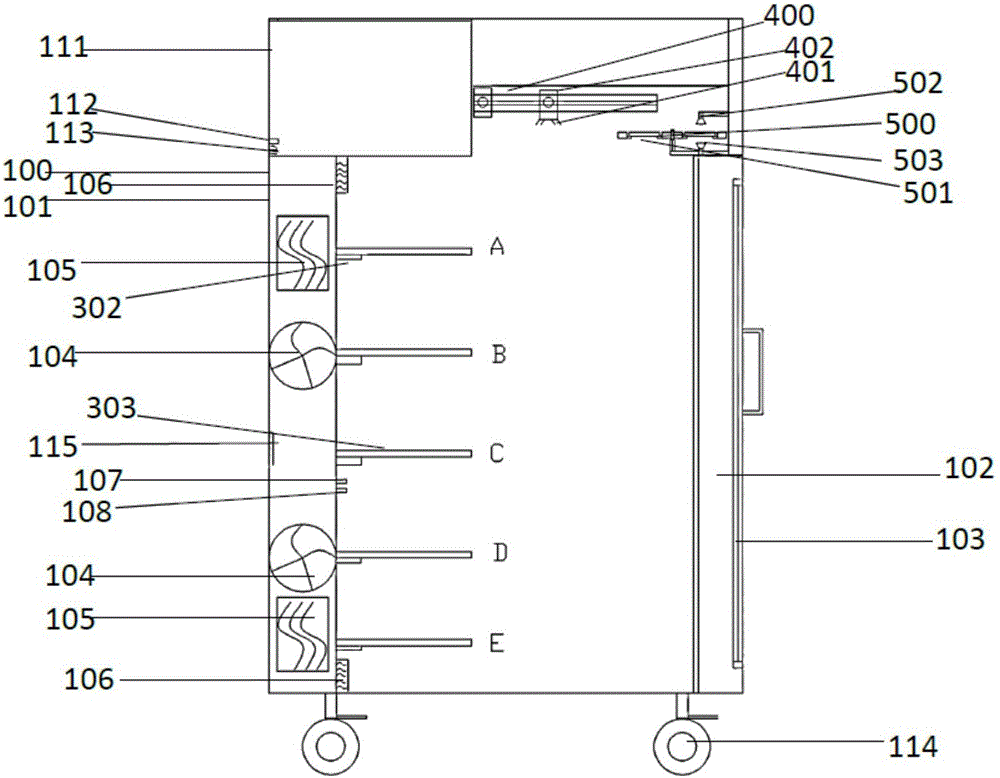

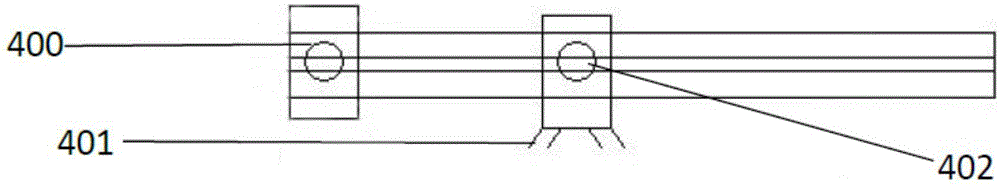

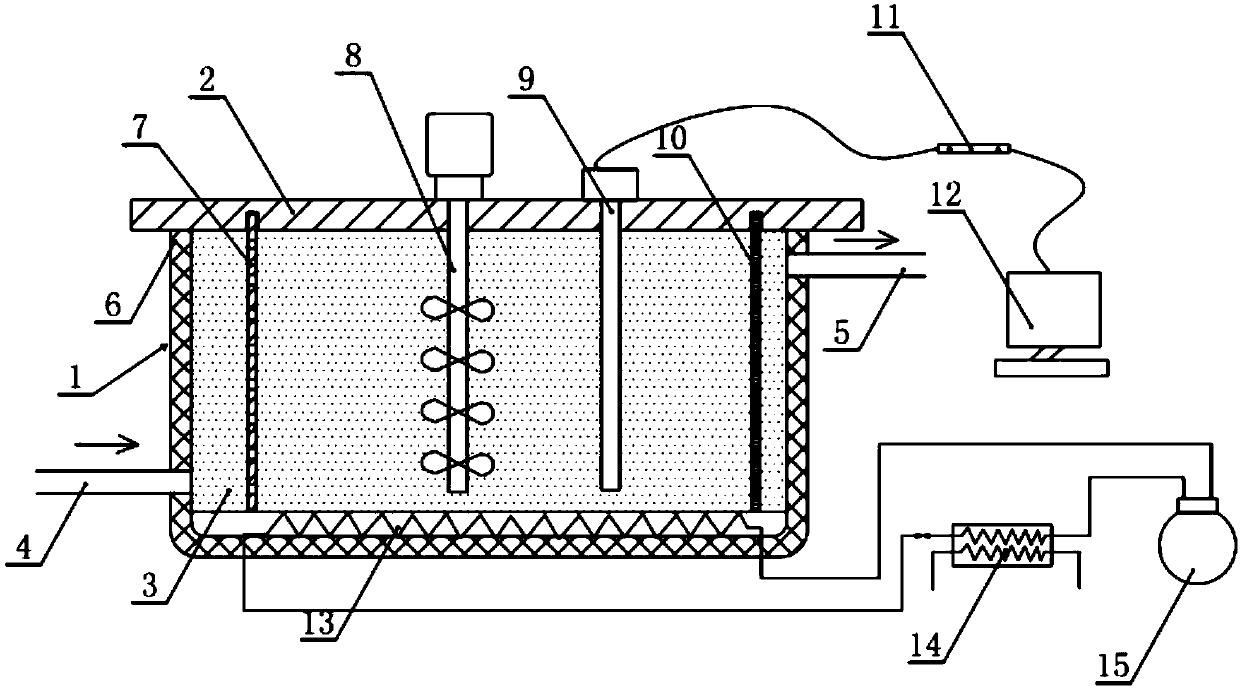

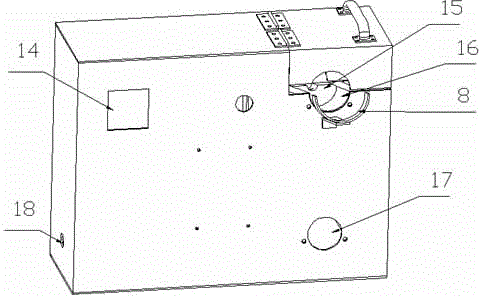

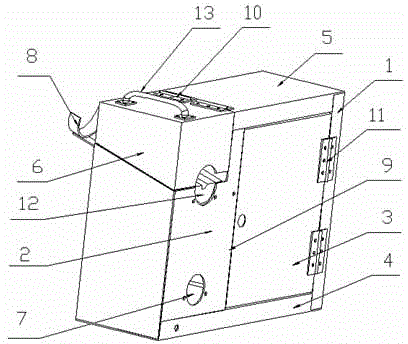

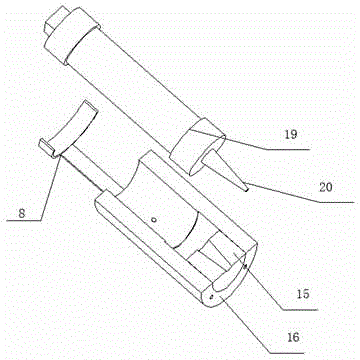

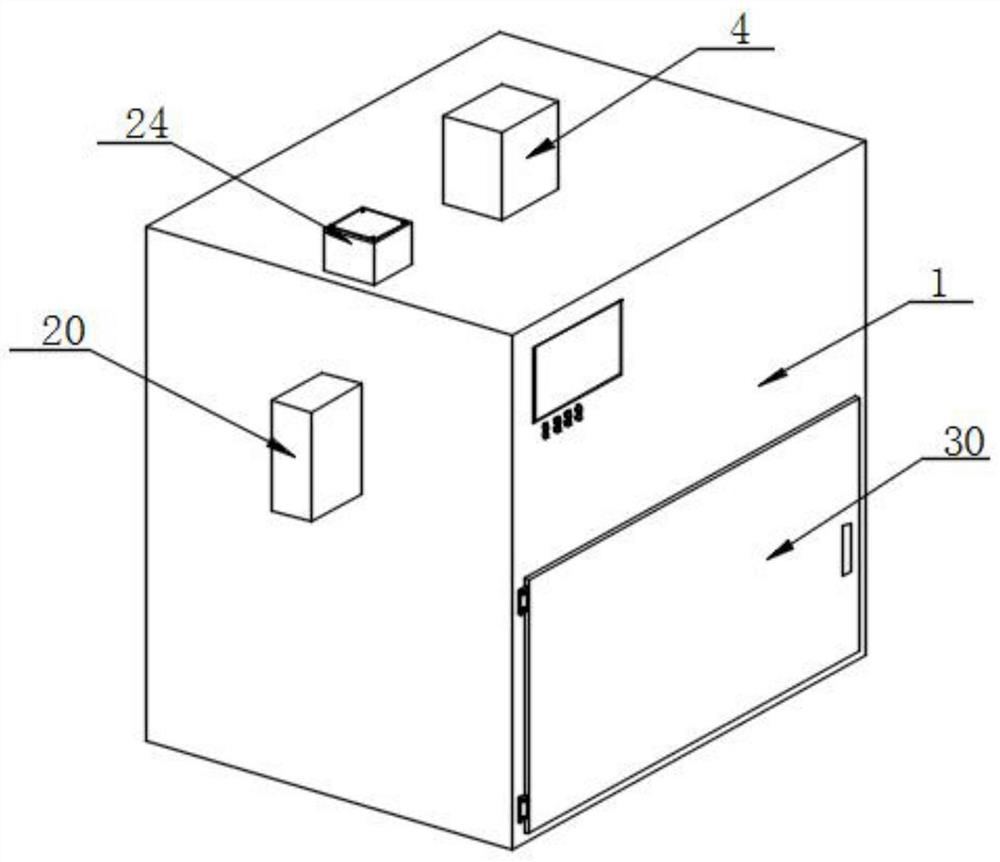

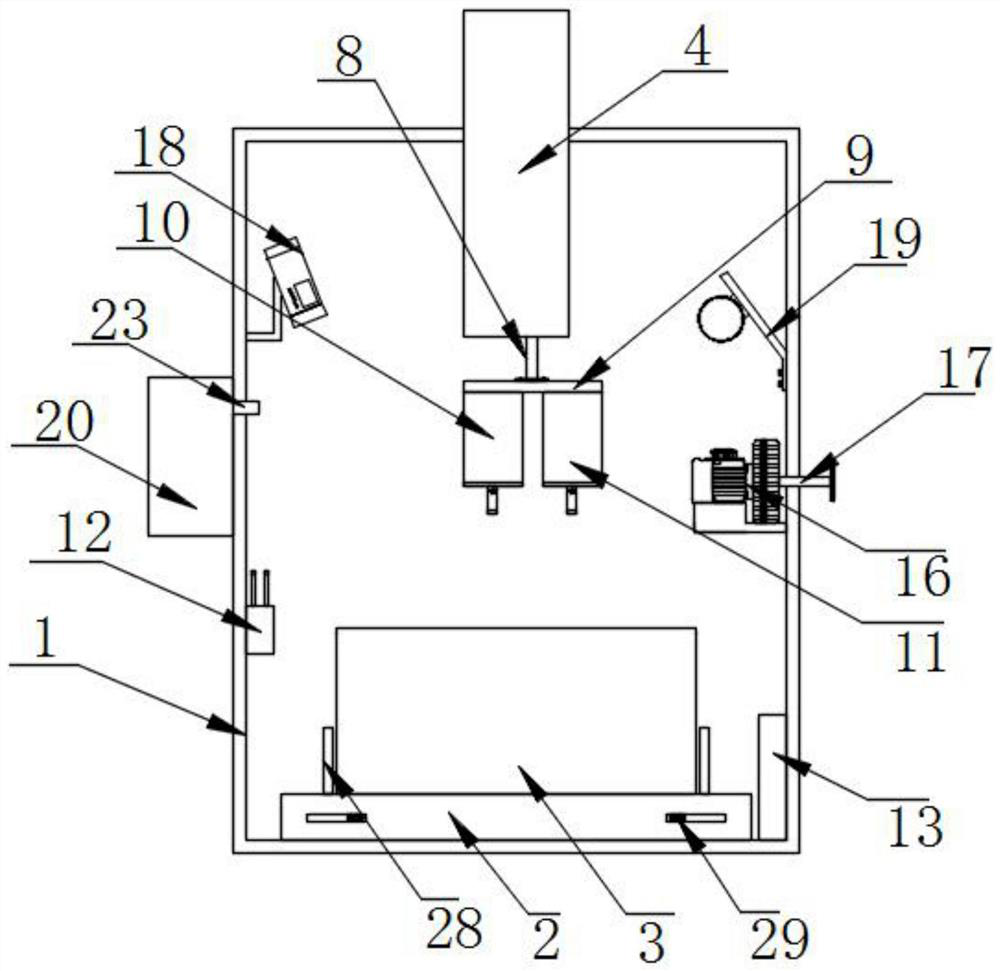

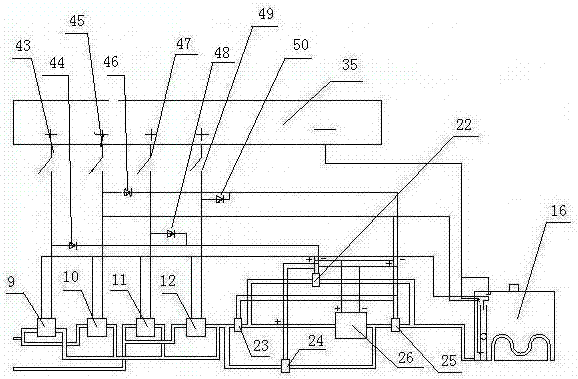

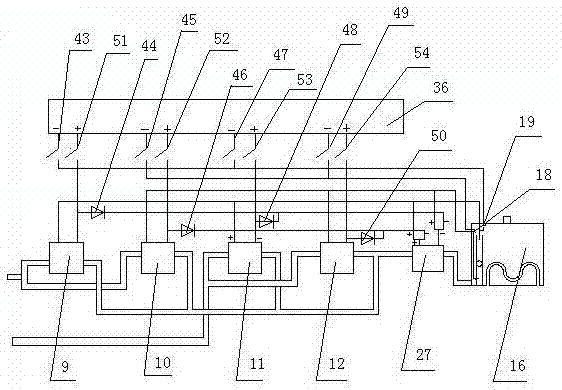

Indoor experimental simulation device for causing corrosion of metallic materials by direct-current stray current

PendingCN108444899AAvoid electromagnetic interferenceReal-time humidity controlWeather/light/corrosion resistanceNumerical controlMetallic materials

The invention discloses an indoor experimental simulation device for causing corrosion of metallic materials by a direct-current stray current, and belongs to the technical field of metallic materialcorrosion testing. The device comprises a numerical controlled socket, a grounding wire, a box body, a temperature control system, a humidity control system, a corrosion experimental system and an electrochemical testing system, the temperature control system and the humidity control system are fixed on the box body, the corrosion experimental system and the electrochemical testing system are located in the box body, the socket is located on the box body, and the grounding wire is arranged at the bottom of the box body. By means of the indoor experimental simulation device, simulation experiments in which corrosion is generated by the metallic materials under the influences of a stray current under laboratory conditions can be achieved while the corrosion process can be monitored through the electrochemical testing system; the experiments can be conducted under constant-temperature and constant-humidity conditions due to controllable environmental temperature and humidity. In addition,the structure of the device is simple, sample placing and taking are easy, and the production cost is low.

Owner:KUNMING UNIV OF SCI & TECH +1

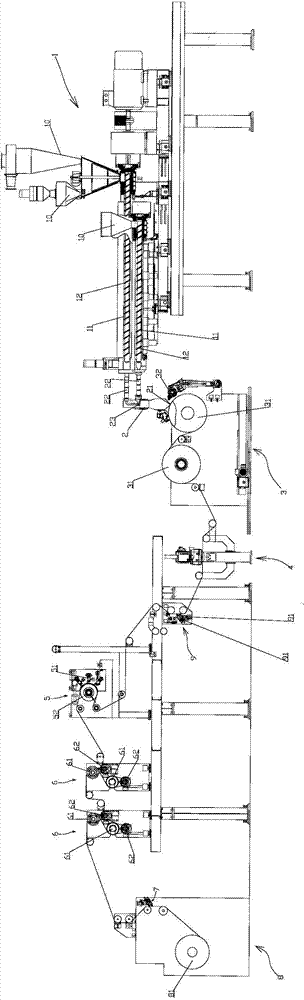

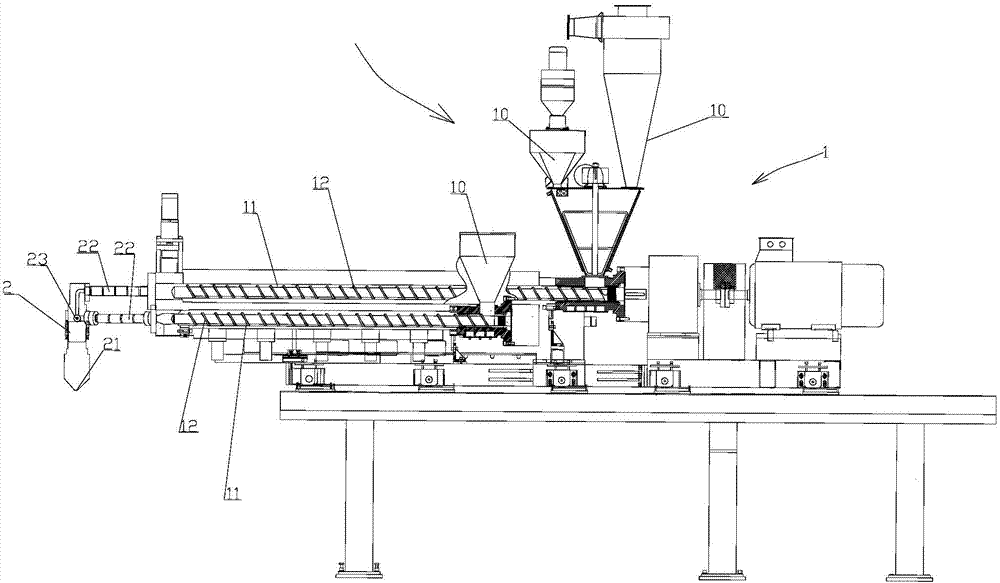

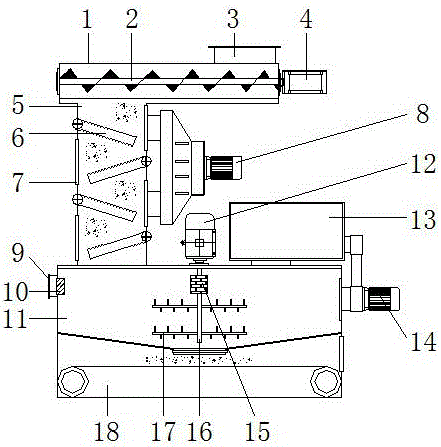

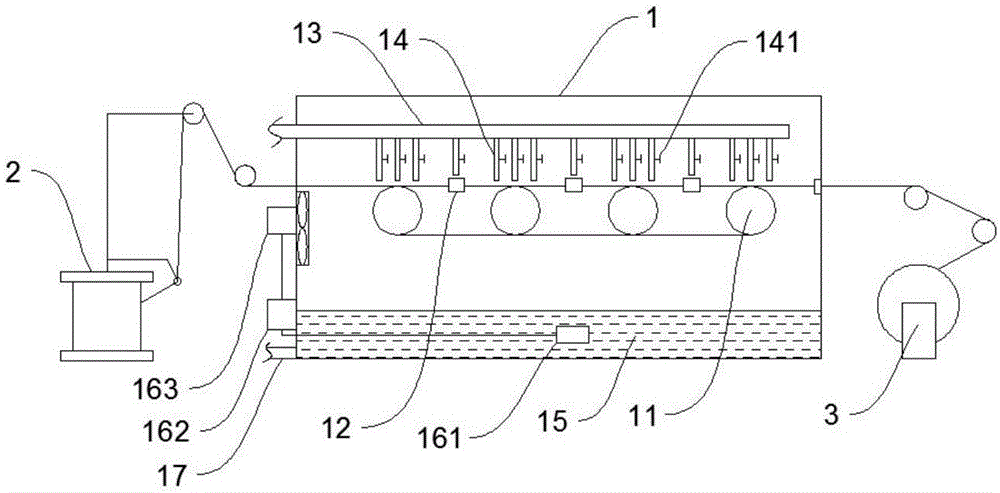

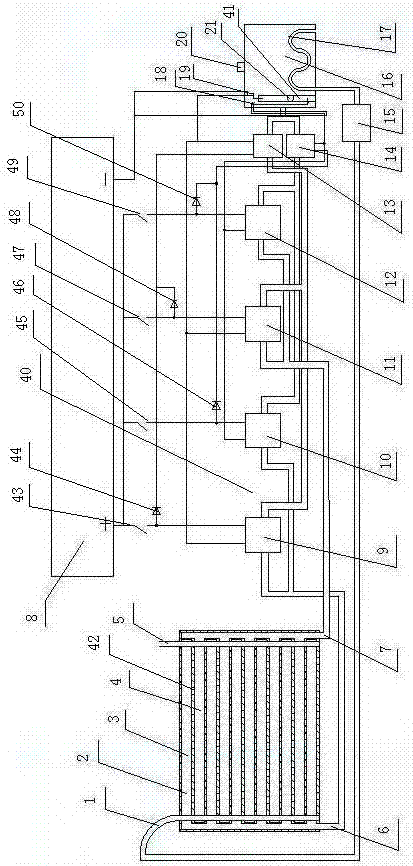

Composite packaging film forming process and making device

InactiveCN104494154AReal-time temperature controlEffective precipitationFlat articlesCoatingsEngineeringHigh voltage electrode

The invention relates to a composite packaging film forming process which has a technical key point of comprising the following steps: a, feeding; b, raw material extruding; c, raw material mixing; d, tape-casting; e, thin film thickness measuring; f, electrode corona; g, tempering; h, trimming; and I, finished product recovering. The invention further relates to a making device of a composite packaging film. The making device comprises an extruder, a raw material mixer, a tape-casting unit, a thickness-measuring unit, a corona unit, a tempering unit and a winding unit, wherein a raw material adding hole, an extruding cavity and an extruding rod are arranged on the extruder; a raw material reflowing hole is formed in the raw material mixer; the tape-casting unit is arranged at one side of the raw material reflowing hole, and a cooling traction roll is arranged on the tape-casting unit; a corona guide rotary roll and a high-voltage electrode are arranged on the corona unit; a plurality of heating rotary rolls are arranged on the tempering unit; a cutter device and a winding roll arranged at one discharging side of the cutter device are arranged on the winding unit. The composite packaging film forming process is simple and is high in yield; the making device is simple in structure and can be used for preferably precipitating a smooth opening agent.

Owner:SOTECH SMARTER EQUIP CO LTD

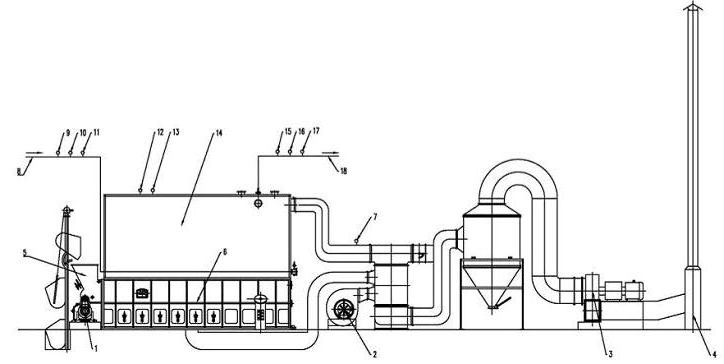

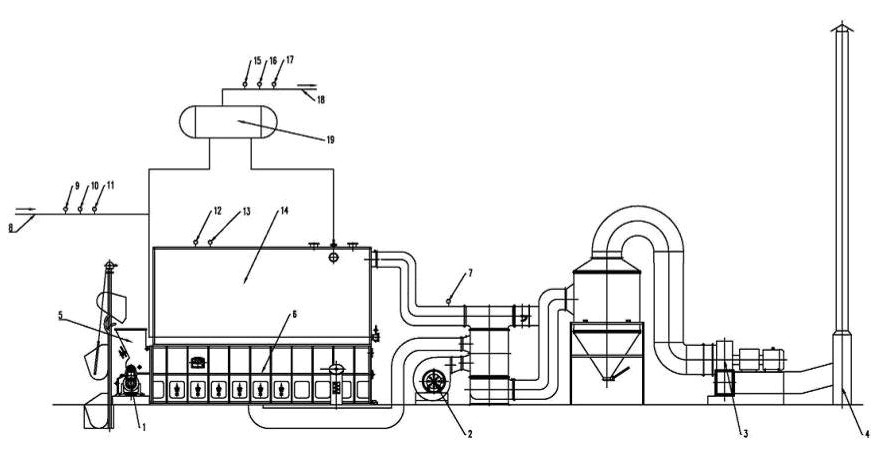

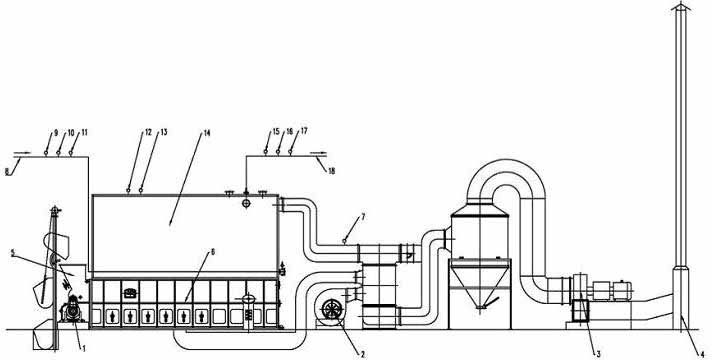

Drying machine for grain production

InactiveCN106813479AQuality impactNovel structureGas current separationDrying gas arrangementsAgricultural engineeringProduct gas

The invention discloses a drying machine for grain production. The drying machine comprises a feeding chamber, a spiral feeding rod, a feeding port, a driving device, an air outlet, a humidity detecting device, a motor, a steam boiler, an air blower, a temperature regulating device, a mixing shaft, mixing blades and a conveying device, wherein the spiral feeding rod is fixed to the inner side of the feeding chamber, and the right end of the spiral feeding rod is connected with the driving device; a drying chamber is fixed to the bottom side of a rust removing pipe; the steam boiler which is connected with the air blower is positioned at the upper right of the drying chamber; a motor is mounted at the left side of the steam boiler, and the bottom end of the motor is connected with the mixing shaft; the temperature regulating device is embedded into the outer wall of the mixing shaft; the mixing blades are arranged at two sides of the mixing shaft. The drying machine for the grain production is simple and novel in structure; the feeding speed can be freely controlled through the spiral feeding rod; the humidity of the discharged air can be detected through the humidity detecting device; the materials can be fed after the humidity meets the requirement, so that the drying efficiency can be greatly improved.

Owner:周华宾

Automatic control method for burner type industrial boiler and device for automatic control method

InactiveCN102353073APrecise temperature controlAccurately control supplyCombustion regulationAutomatic controlHeat carrier

The invention relates to an automatic control method for a burner type industrial boiler and a device for the automatic control method, and belongs to the field of boilers. A heat carrier temperature parameter, a furnace box temperature parameter, a furnace box negative pressure parameter, a furnace box flue gas component content parameter, a heat carrier flow parameter and a heat carrier pressure parameter are subjected to software analysis and expert database reasoning operation, the optimal data of a fuel supply amount, a combustion air amount and the furnace box negative pressure is determined in real time, the opening of a fuel supply regulating valve and a nozzle of a burner, the opening of a combustion air regulating valve, and the rotating speed of an induced draft fan motor are controlled in real time, and the fuel supply amount, the combustion air amount and the furnace box negative pressure are controlled in real time. The system can accurately control the fuel supply amount, the combustion air amount and the furnace box negative pressure in real time, accurately controls the output heat carrier temperature, saves fuel and electric energy, and fulfills the aims of saving energy, reducing emission and reducing consumption.

Owner:威海宝源电气有限公司

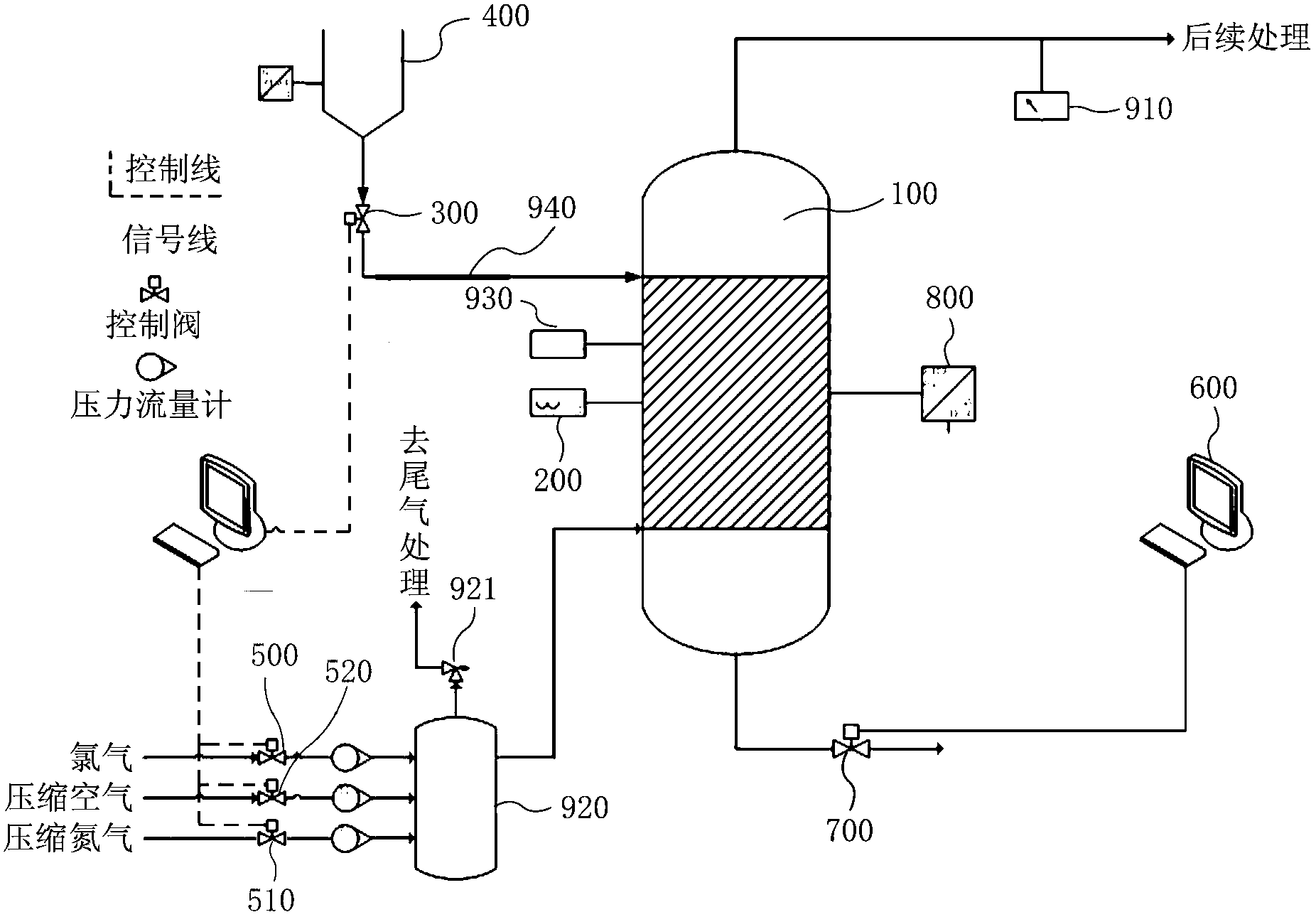

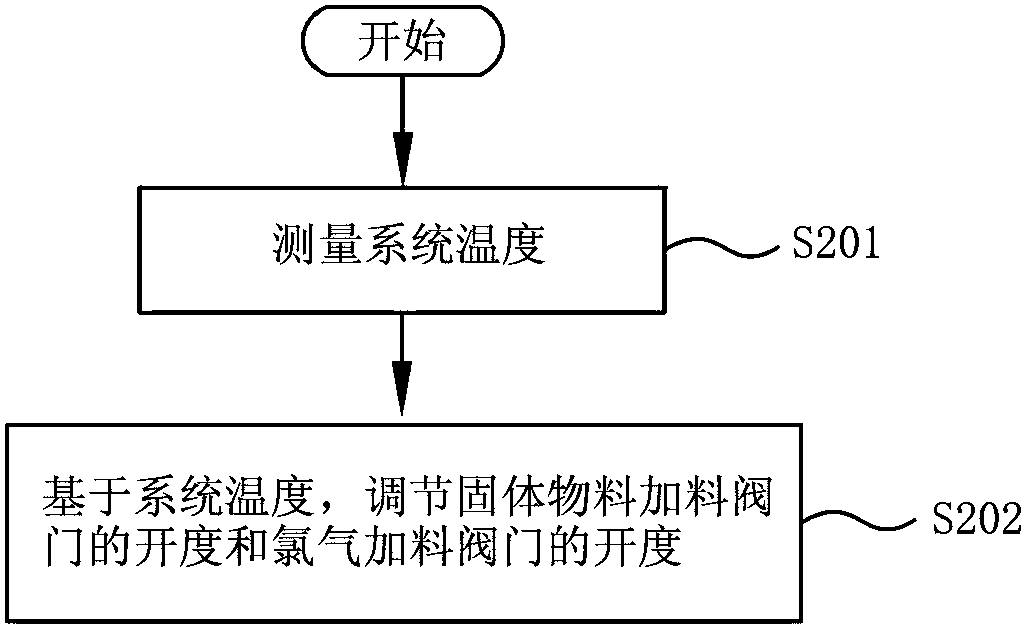

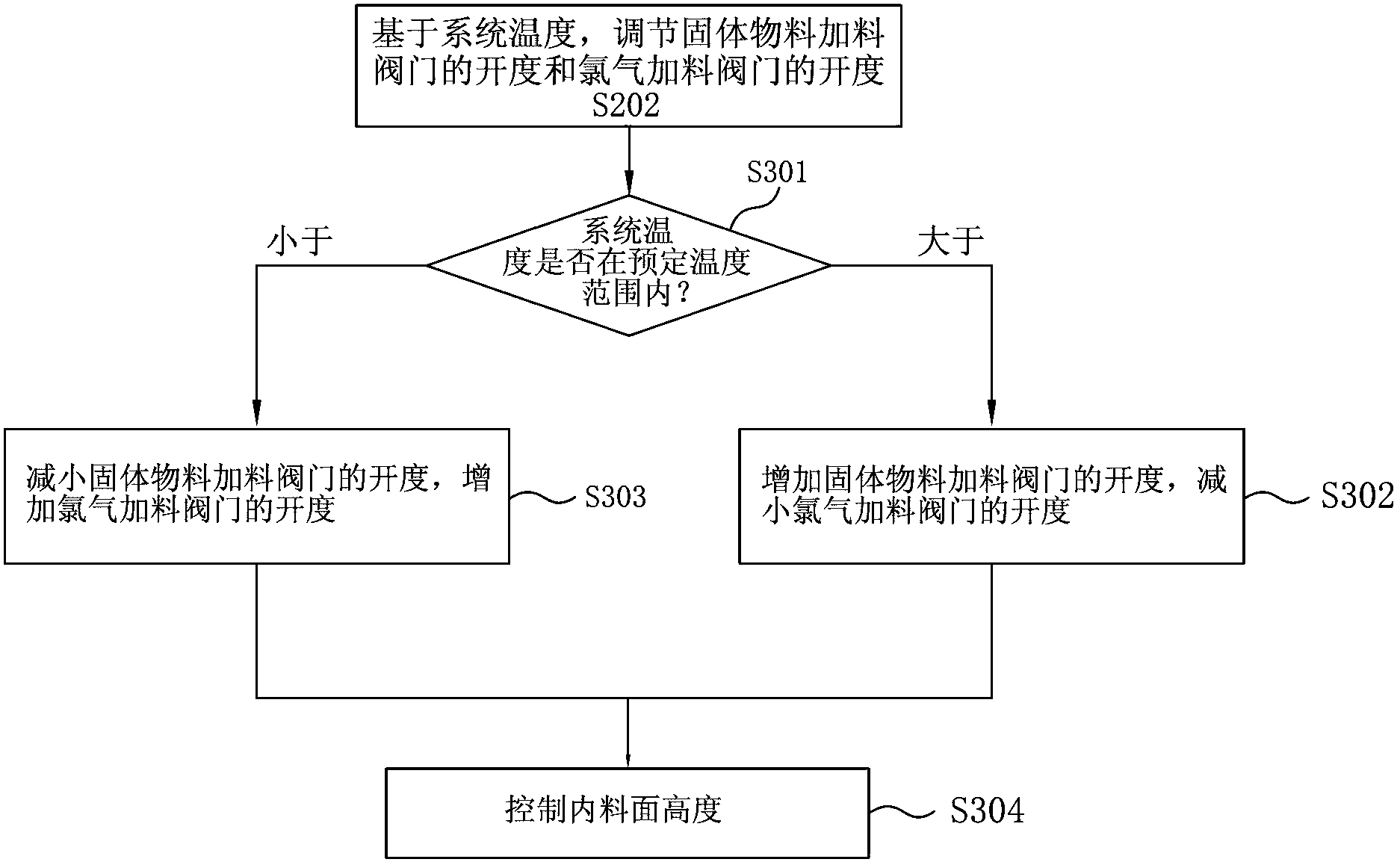

Control system and control method for low temperature fluidizing chlorination furnace

ActiveCN103058270AReal-time control system temperatureReal-time temperature controlTitanium halidesControl systemSlag

The invention provides a control system and a control method for a low temperature fluidizing chlorination furnace. The control system for the low temperature fluidizing chlorination furnace comprises a thermometer which is arranged in the low temperature fluidizing chlorination furnace for measuring a system temperature in the low temperature fluidizing chlorination furnace, a solid material feeding valve which is mounted between the low temperature fluidizing chlorination furnace and a raw material cabin providing carbonized blast furnace slag to the low temperature fluidizing chlorination furnace and is used for controlling addition amount of the carbonized blast furnace slag, a chlorine feeding valve which is arranged between and connected with a chlorine source and the low temperature fluidizing chlorination furnace and is used for controlling air inflow of chlorine, and a controller which adjusts the opening degrees of the solid material feeding valve and the chlorine feeding valve based on the system temperature measured by the thermometer. With the control system and the control method for the low temperature fluidizing chlorination furnace, real time control of the system temperature and the height of an inner material level of the low temperature fluidizing chlorination furnace can be realized, so a production process for titanium tetrachloride can be safely and highly efficiently carried out.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

AGC (automatic gain control) control method for 660MW supercritical unit under deep peak-load regulation

The invention belongs to the technical field of AGC (automatic gain control) control and discloses an AGC control method for a 660MW supercritical unit under deep peak-load regulation. The method includes: when a unit load enters a deep peak-load regulation range, subjecting flow of steam pumps to minimum flow limitation; when the flow of each single steam pump is smaller than 435T / H, enabling a steam pump recirculation valve to participate in steam pump inlet flow regulation, slowly opening, and keeping each steam pump operating above minimum output; increasing smoke temperature on a boiler side, and slowly closing a denitrification wide load baffle along with the unit load to keep smoke temperature under a low unit load condition; after the unit load enters the deep peak-load regulationrange, automatically reducing the rate through AGC rate judgment, and enabling boiler master control and steam engine master control PID self-adaption variable-parameter control through AGC control, so that automatic control quality can be improved. Automatic control of the steam feed pump recirculation valve and the denitrification wide load baffle along with the unit load, AGC automatic controlunder deep peak-load regulation, steam engine master control PID self-adaption control and boiler master control PID self-adaption control are realized.

Owner:MAANSHAN DANGTU POWER GENERATION

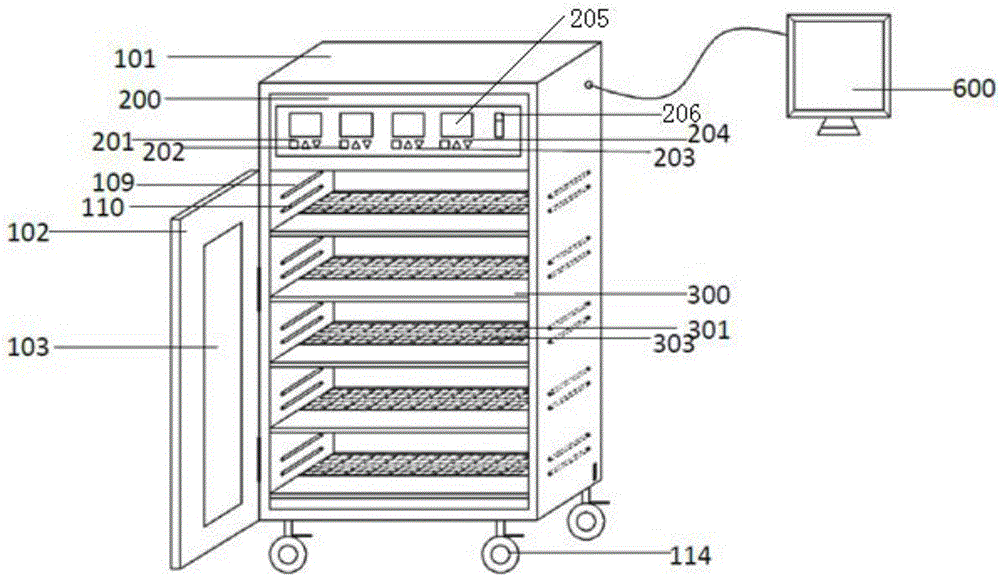

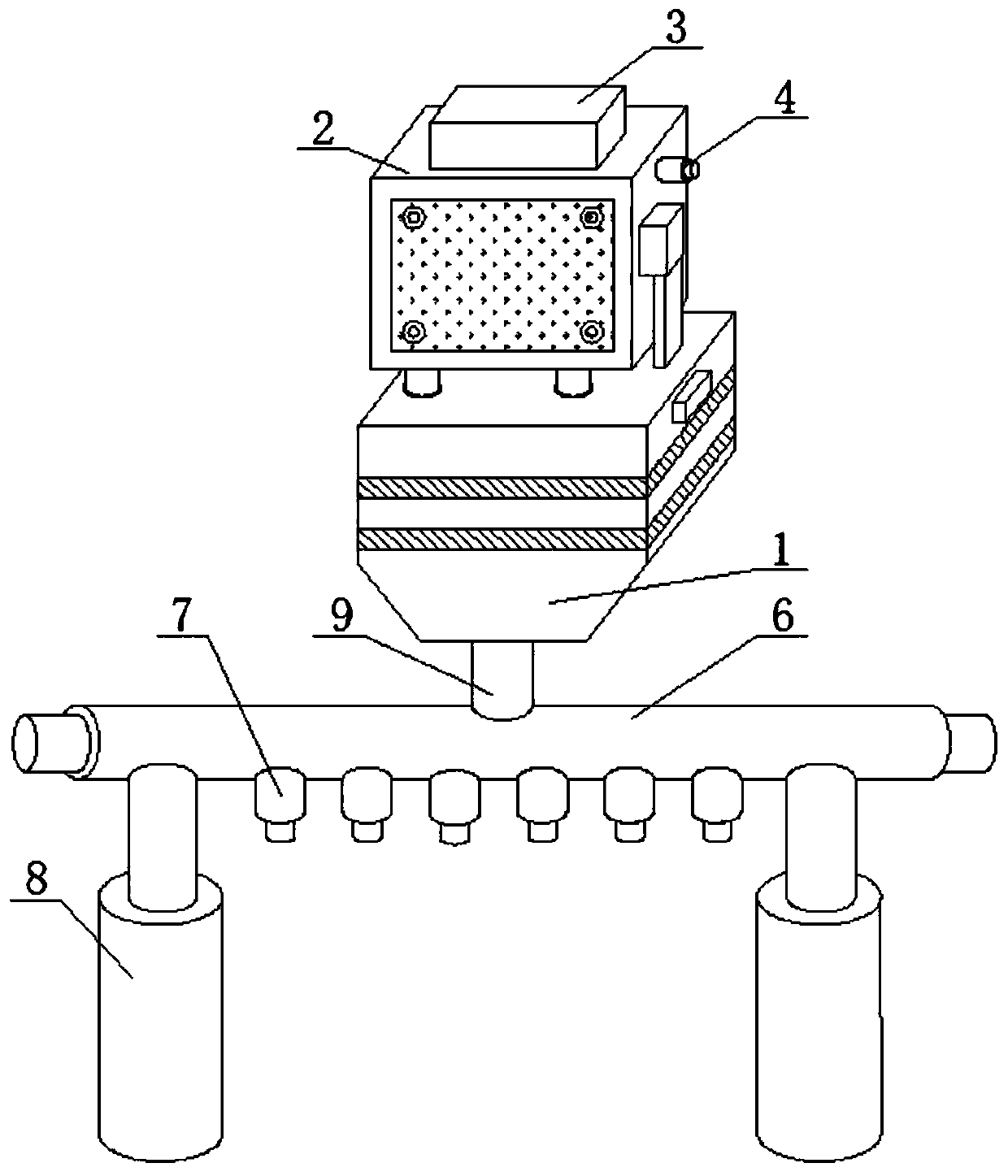

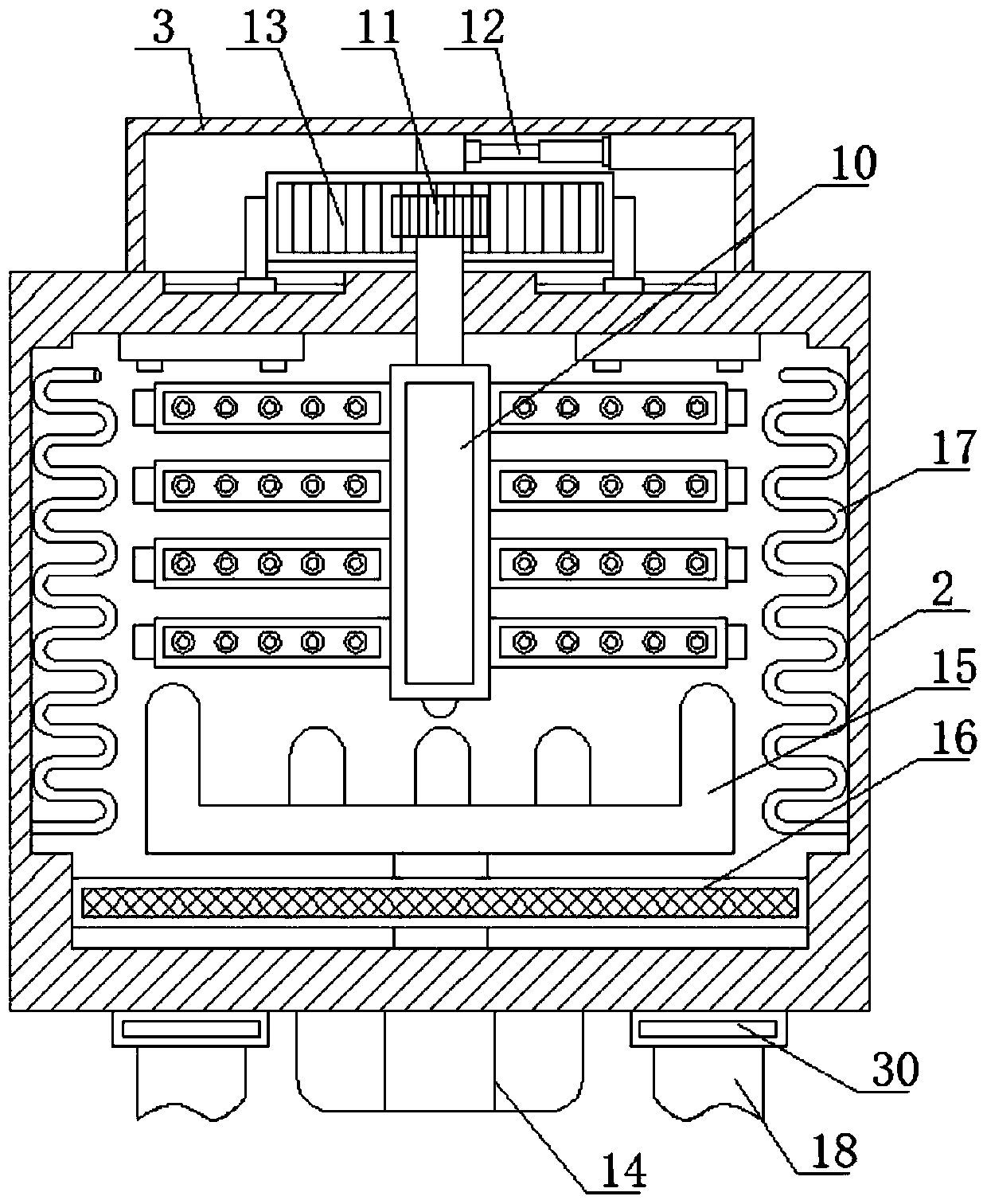

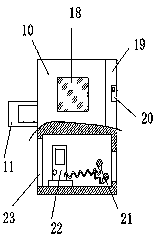

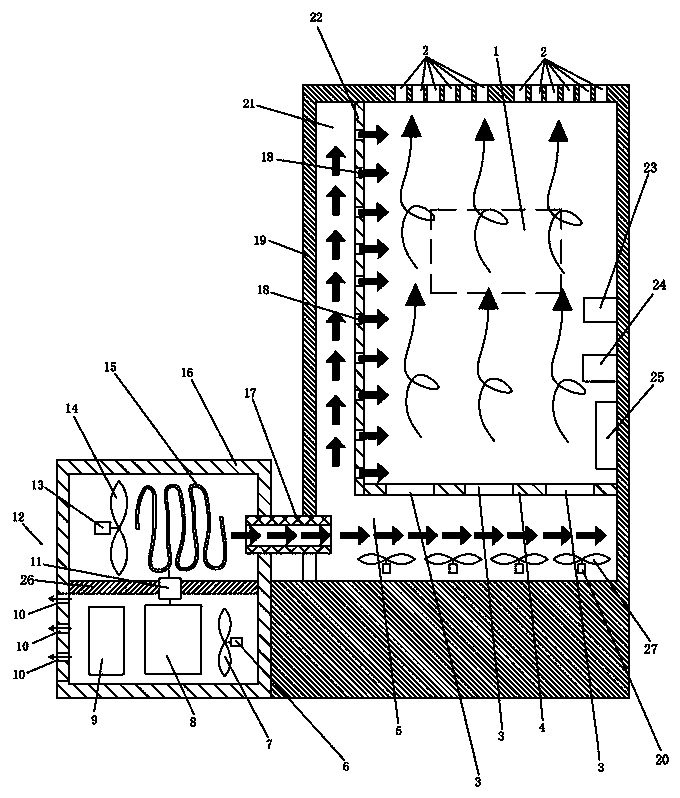

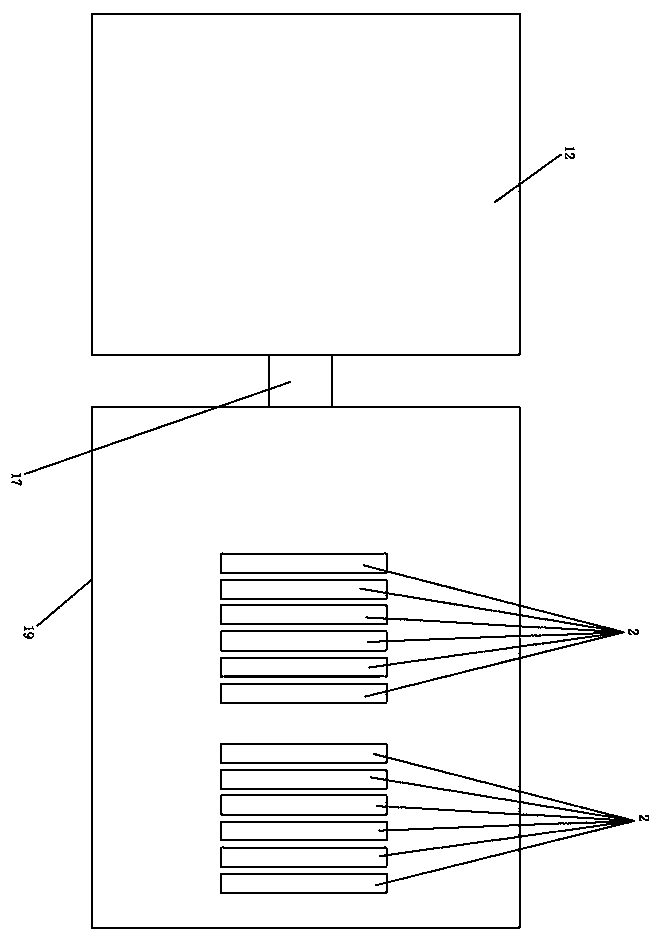

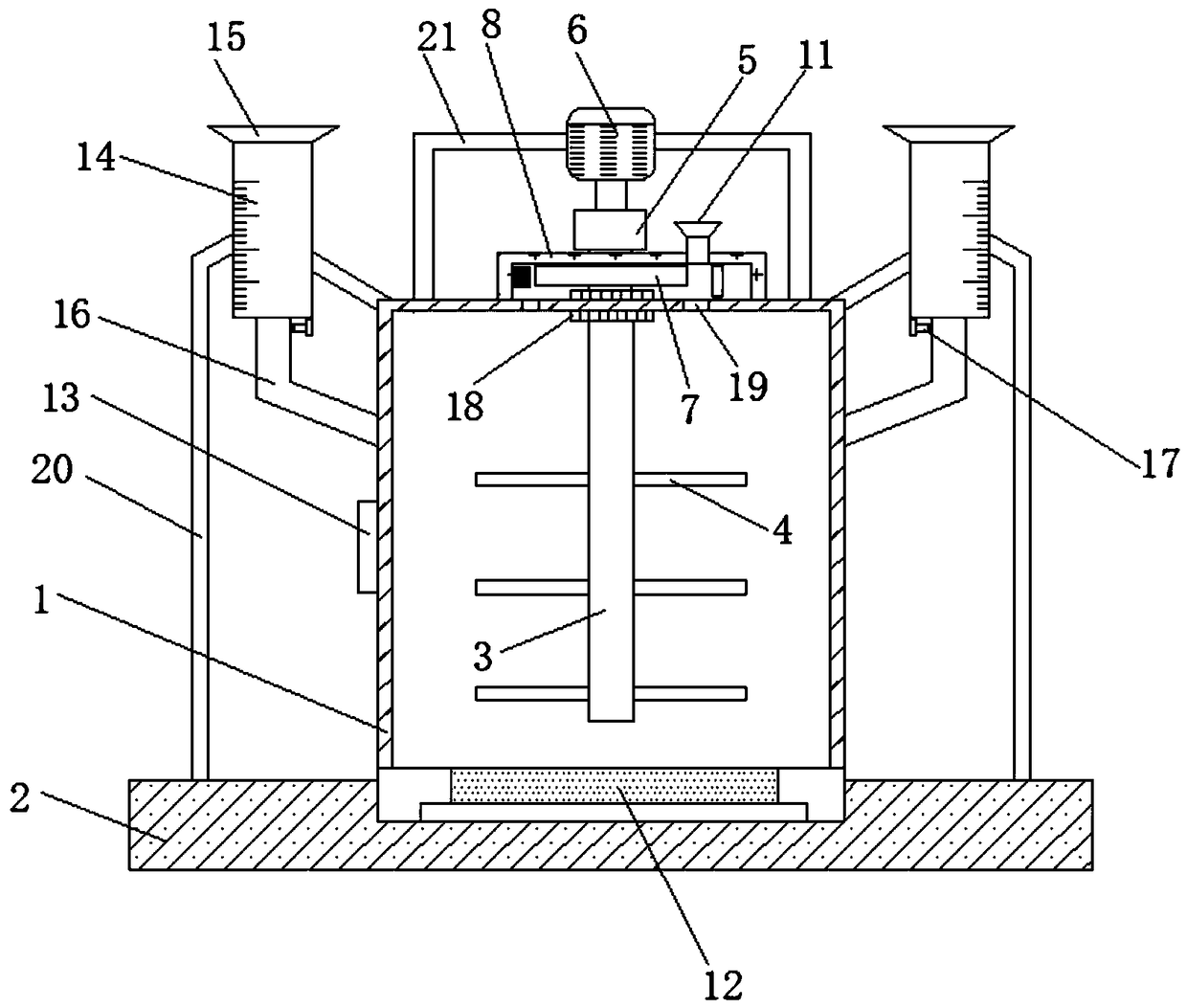

Multifunctional incubator

InactiveCN105779286AEasy to operateIncrease light intensityBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismTemperature control

The invention discloses a multifunctional incubator which comprises an incubator body mechanism, a tray mechanism, a grabbing mechanism, an observation mechanism and a computer. The multifunctional incubator controls the tray mechanism, the grabbing mechanism and the observation mechanism through the computer, so as to online monitor growth situations of microorganisms in the incubator body mechanism, record the growth situation of microorganisms in each time period, provide real and reliable growth reports with pictures and data, and overcome the disadvantage that the existing incubator cannot obtain detection results regularly; the multifunctional incubator realizes real-time regulation and control of the temperature and humidity for microorganism cultivation by being provided with a humidity controller, a temperature controller and various components matched with the controllers, ensures that the microbiological culture medium is kept within a more stable environment, which is beneficial to the growth of microorganisms, ensures that bacterial colonies are clear and distinguishable, improves the testing accuracy, and avoids artificial counting errors.

Owner:苏交科集团(江苏)安全科学研究院有限公司

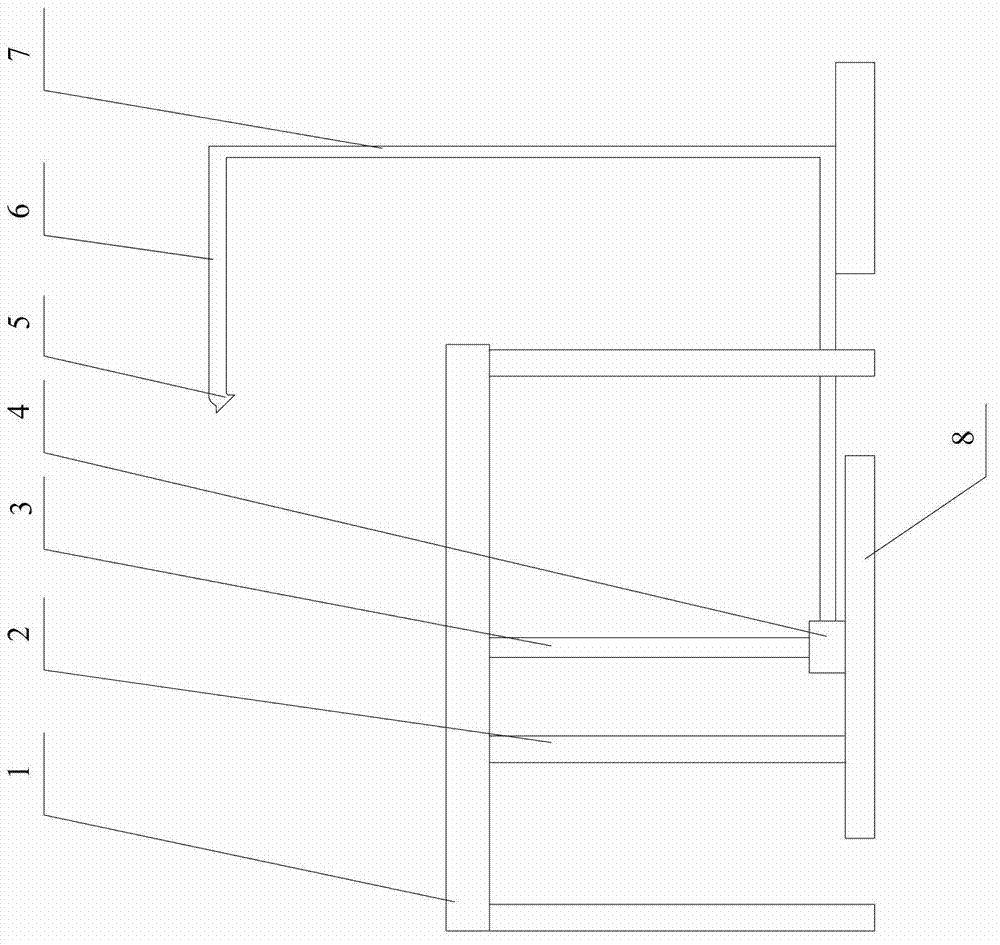

Chemical-adding drip irrigation device for agriculture

PendingCN110663513ASpeed up the flowImprove mixing efficiencyTransportation and packagingRotary stirring mixersAgricultural engineeringDrip irrigation

The invention belongs to the technical field of drip irrigation, particularly relates to a chemical-adding drip irrigation device for agriculture, and aims to solve the problems that an existing dripirrigation device is prone to scaling and drip pipe blocking, additional chemical application to land is needed, and artificial planting cost is increased. According to the technical scheme, the chemical-adding drip irrigation device comprises a flow limit tank and is characterized in that a mixing tank is fixedly connected above the flow limit tank, a liquid outlet pipe is fixedly connected to the bottom of the flow limit tank in a communicated manner, a drip pipe is fixedly connected to the bottom of the liquid outlet pipe in a communicated manner, two symmetrically-arranged support rods arefixedly connected to the top of the drip pipe, a plurality of drip ports are arranged at the bottom of the drip pipe in a communicated manner, and a chemical adding pipe is fixedly connected to one side of the mixing tank in a communicated manner. The chemical-adding drip irrigation device has the advantages that the device is simple in structural design and capable of achieving chemical adding,chemicals can be applied to crops during drip irrigation, manpower is liberated, impurities in water can be filtered, and drip pipe blocking can be prevented.

Owner:康浩东

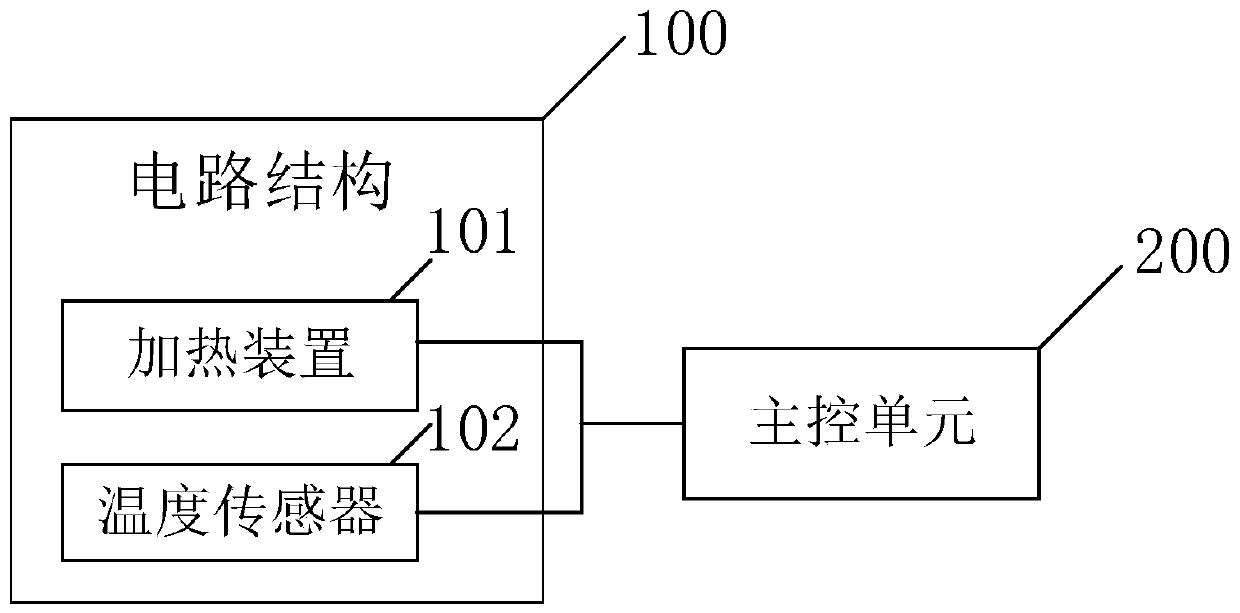

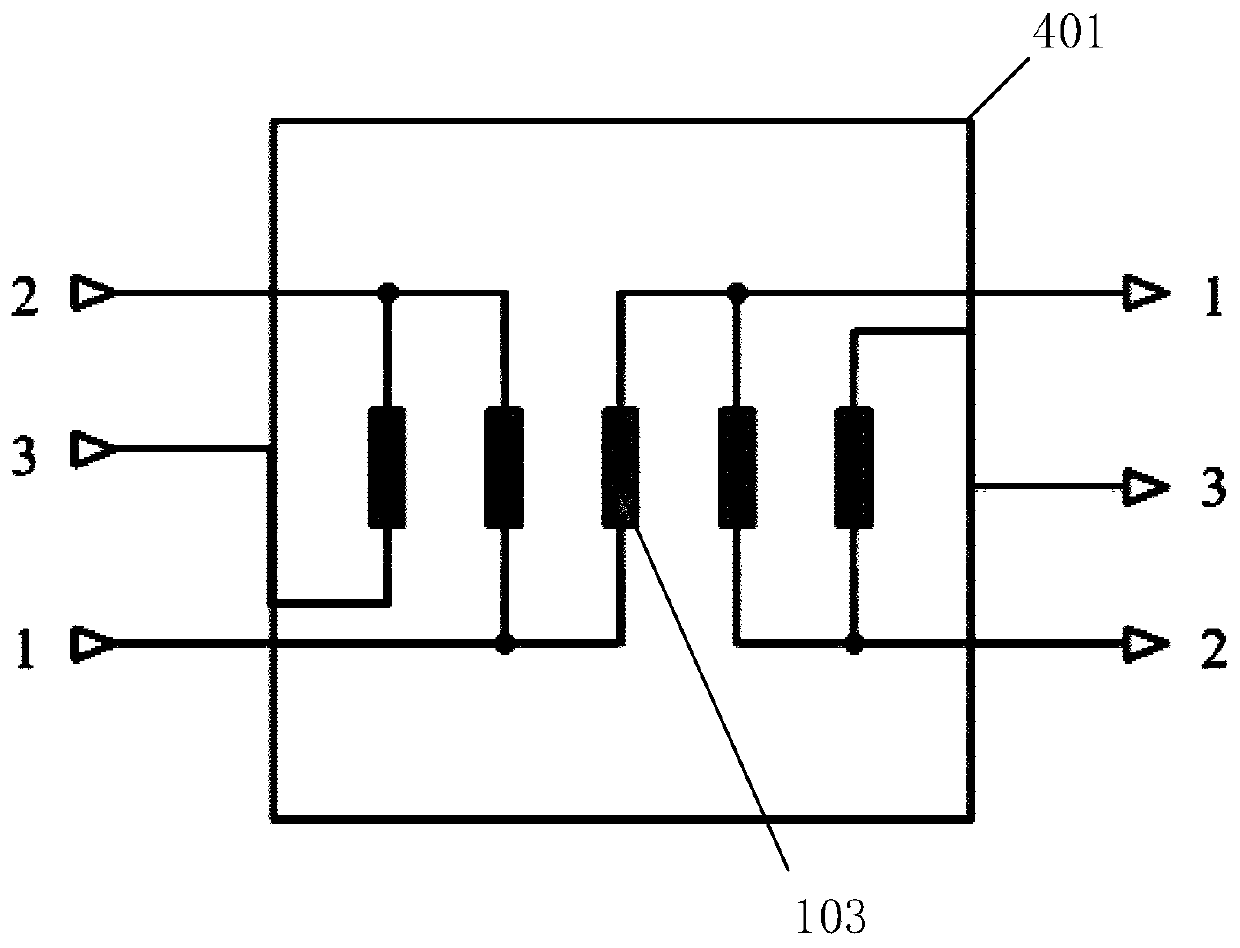

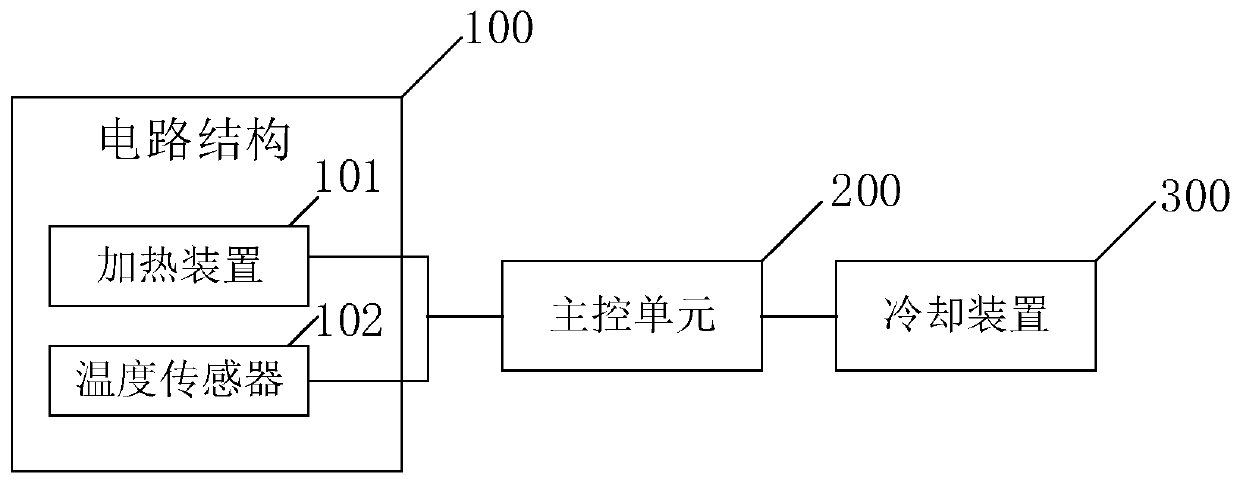

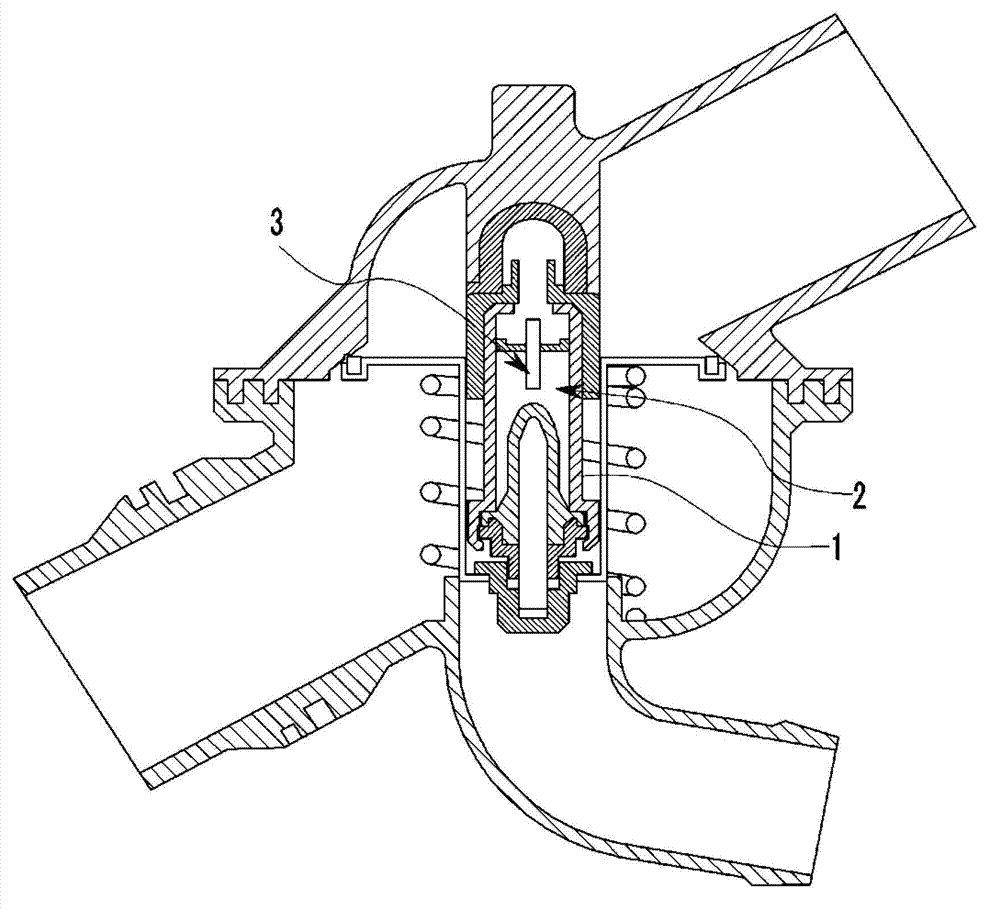

Temperature control system, detection system and temperature control method of micro-fluidic chip

ActiveCN111266139AExcellent performancePrecise temperature controlTemperature control using plurality of sensorsThermometers using electric/magnetic elementsMicrofluidic chipThermistor

The embodiment of the invention provides a temperature control system, a detection system and a temperature control method of a micro-fluidic chip. The temperature control system comprises a circuit structure which is used for being arranged in the functional layer in the micro-fluidic chip and corresponding to the reaction area of the micro-fluidic chip, wherein the circuit structure comprises atleast two thermistors and a plurality of ports and the ports comprises an input end and an output end; and a main control unit which is electrically connected with each port and is used for selectingdifferent input ends and / or different output ends to form use circuits with different resistance values so that the circuit structure can be switched between being used as a heating device and beingused as a temperature sensor. The two multiplexing functions of the circuit structure do not interfere with each other, the temperature of the reaction area can be controlled in real time, it is guaranteed that the reaction area is always at the needed temperature without additionally increasing the size of the temperature control system or the size of the detection system and the cost is low.

Owner:BOE TECH GRP CO LTD +1

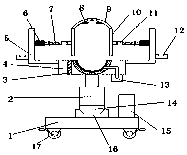

Novel head fixing device for ophthalmologic examination

InactiveCN107898510AMeet the needs of useFree height adjustmentEye diagnosticsInstruments for stereotaxic surgeryHydraulic cylinderEngineering

The invention belongs to the technical field of ophthalmologic instruments, in particular to a novel head fixing device for ophthalmologic examination, and aims at solving the problem of uncomfortableuse when the ophthalmologic examination is performed on a patient by means of the head fixing device. A scheme is proposed, and the head fixing device includes a base, universal wheels with brakes are fixed to the four corners of the bottom outer wall of the base through screws, and an electrically controlled slide rail is fixed to the top outer wall of the base through screws; the top inner wall of the electrically controlled slide rail is slidably connected with a sliding block, and a hydraulic cylinder is fixed to the top outer wall of the sliding block through screws; a support plate isfixed to one end of a piston rod of the hydraulic cylinder through bolts, fixing plates are fixed to the outer walls at both sides of the support plate through screws, the fixing plates are of L-shaped structures, and servo motors are fixed to the outer walls at one sides of the two fixing plates through screws. The head fixing device can move freely, and the height of the head fixing device can be freely adjusted, so that psychology stress of the patient can be reduced when eyes are inspected, thereby avoiding the phenomenon that the scalp is bruised by overhardening strap snaps.

Owner:许桂敏

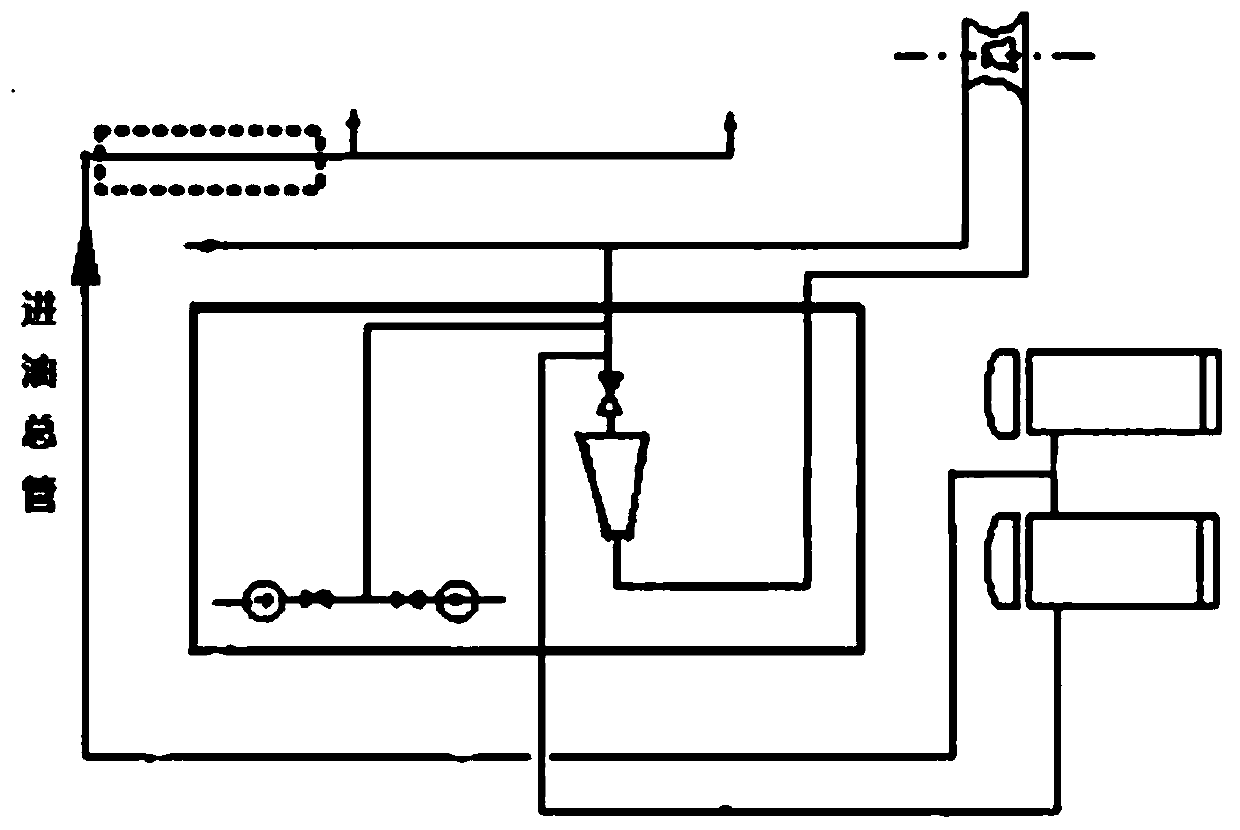

Turbine lubricating oil temperature online regulating device with precise temperature control

InactiveCN108679435APrecise lubricating oil temperatureImprove stability and security featuresLubrication elementsFuel tankStart up

A turbine lubricating oil temperature online regulating device with precise temperature control, the online regulating device is arranged on the oil inlet manifold of the lubricating oil, comprising:a fuel tank, an oil inlet pipe, an oil outlet pipe, a rectifier grid, a stirring rod, a heater, an evaporative cooling device, a temperature controller and the computer. The rectifier grid is arranged on the side of the oil tank near the oil inlet pipe, the fuel tank is arranged with a stirring rod and a heater extending into the oil tank, an evaporative cooling device is also arranged in the oiltank, and the heater and the evaporative cooling device are both in connected to the temperature controller and the computer. The turbine lubricating oil temperature online regulating device with precise temperature control can realize online real-time precise cooling of the lubricating oil. For example, during the start-up process, the unit speed is gradually increased, and the temperature of the lubricating oil is gradually increased. At this time, the temperature of the lubricating oil can be quickly reduced by the temperature control device. The system is simple, easy to install and uninstall, accurately controlling the temperature of the lubricating oil entering the bearing housing, reducing the lag of the adjustment time, and realizing online, real-time and precise temperature control.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

A power distribution cabinet with good heat dissipation effect

PendingCN107591708AUniform circulationReal-time temperature controlSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsEvaporatorPower equipment

The present invention discloses a power distribution cabinet with a good heat dissipation effect, pertaining to the technical field of power equipments. The power distribution cabinet comprises a cabinet body, a controller arranged in the cabinet body, a temperature control system electrically connected with the controller, and a humidity control system, wherein the humidity control system is arranged in the cabinet body and the humidity control system is electrically connected with the controller. The temperature control system comprises a temperature sensor arranged on the inner wall of oneside of the inside of the cabinet body; a refrigerating box, wherein the refrigerating box is arranged close to the cabinet body and the refrigerating box is connected with the cabinet body; and heatdissipation components arranged on the bottom of the inner wall of the cabinet body. The middle part of the refrigerating box is provided with a partition plate. A refrigerating part is located on theupper end of the partition plate, in the refrigerating box. A heat dissipation part is located under the lower end of the partition plate, in the refrigerating box. The refrigerating part comprises abox body, wherein the box body is arranged at the lower end of one side of the cabinet body and the box body is connected with the cabinet body; an evaporator, wherein the evaporator is arranged in the box body and the evaporator is used for refrigerating; a cold air fan used for inducing air; and a cold air motor used for driving the cold air fan. The power distribution cabinet can be used for refrigeration and dehumidification, and the power distribution cabinet has the advantages of convenience for using and good heat dissipation effect.

Owner:YINGTAI GROUP

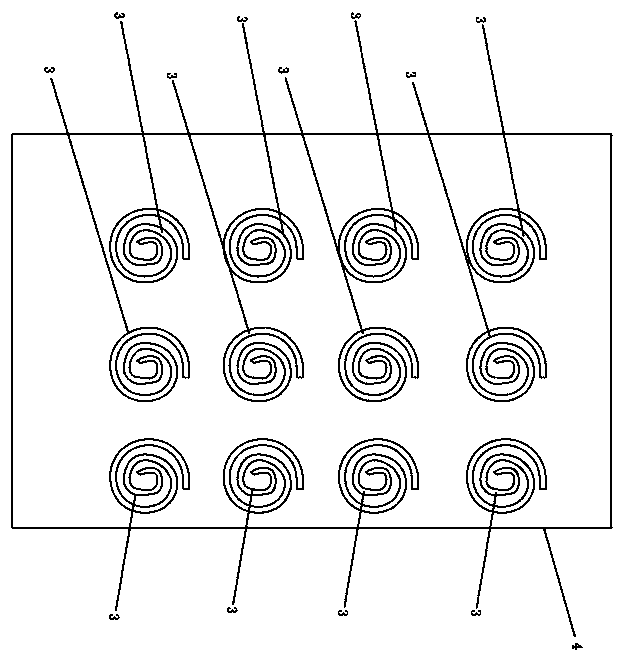

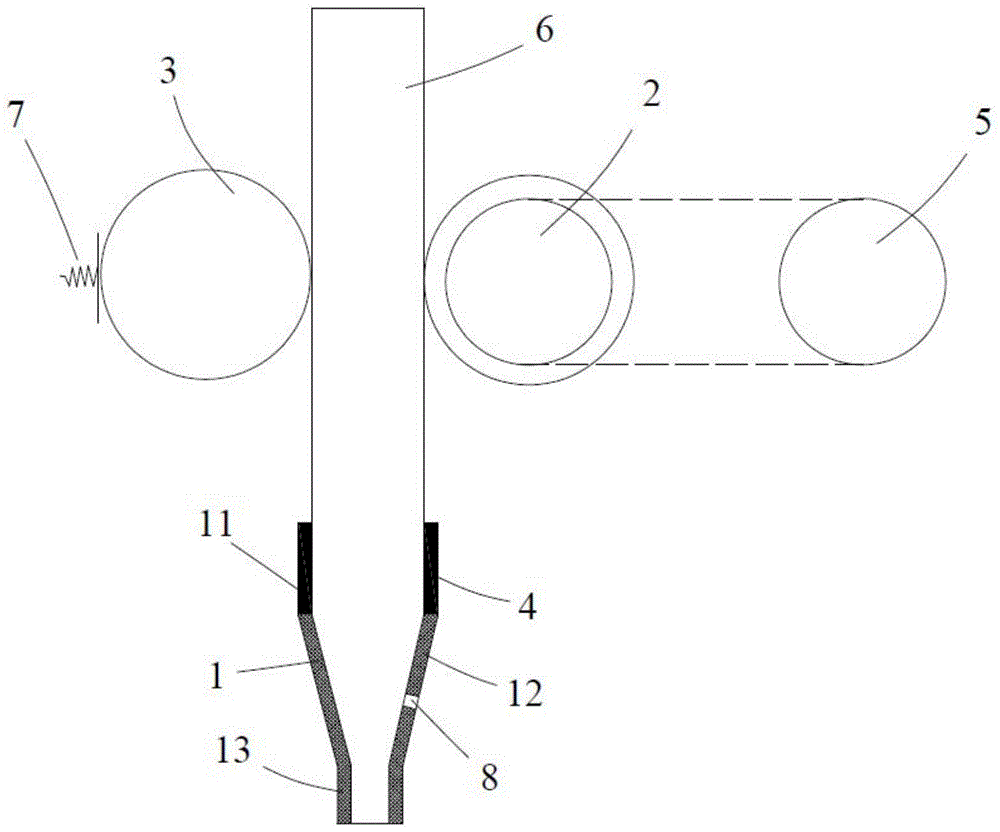

3D printing melt extrusion shower nozzle

InactiveCN104943178AHigh control precisionReal-time temperature controlAdditive manufacturing apparatusElectric machineryConductor Coil

The invention discloses a 3D printing melt extrusion shower nozzle, which comprises a printing head, a driving roller, a driven roller, a heater and a motor, wherein the motor is in transmission connection with the driving roller; an extruding space allowing printing materials to enter is formed between the driving roller and the driven roller; the printing head comprises a main body part provided with a cylindrical cavity, a cone-shaped part connected to the bottom end of the main body part and provided with a cone-shaped cavity, and an ejecting part connected to the bottom end of the cone-shaped part and provided with a cylindrical cavity; and the heater is arranged at the outer side of the main body part in a winding manner. The 3D printing melt extrusion shower nozzle has the advantages that the ejecting part provided with the cylindrical cavity is arranged at a nozzle of the printing head, so that the control precision is high; through the arrangement of a temperature sensor, the temperature of a heating cavity can be controlled in real time, so that the materials can be evenly extruded; and an extruding spring is arranged between the driven roller and printing materials, so that the friction force between the printing materials and the driven roller can be controlled, and the control precision is improved.

Owner:NORTHWESTERN POLYTECHN UNIV ZHANGJIAGANG INTELLIGENT EQUIP TECH INDZATION RES INST

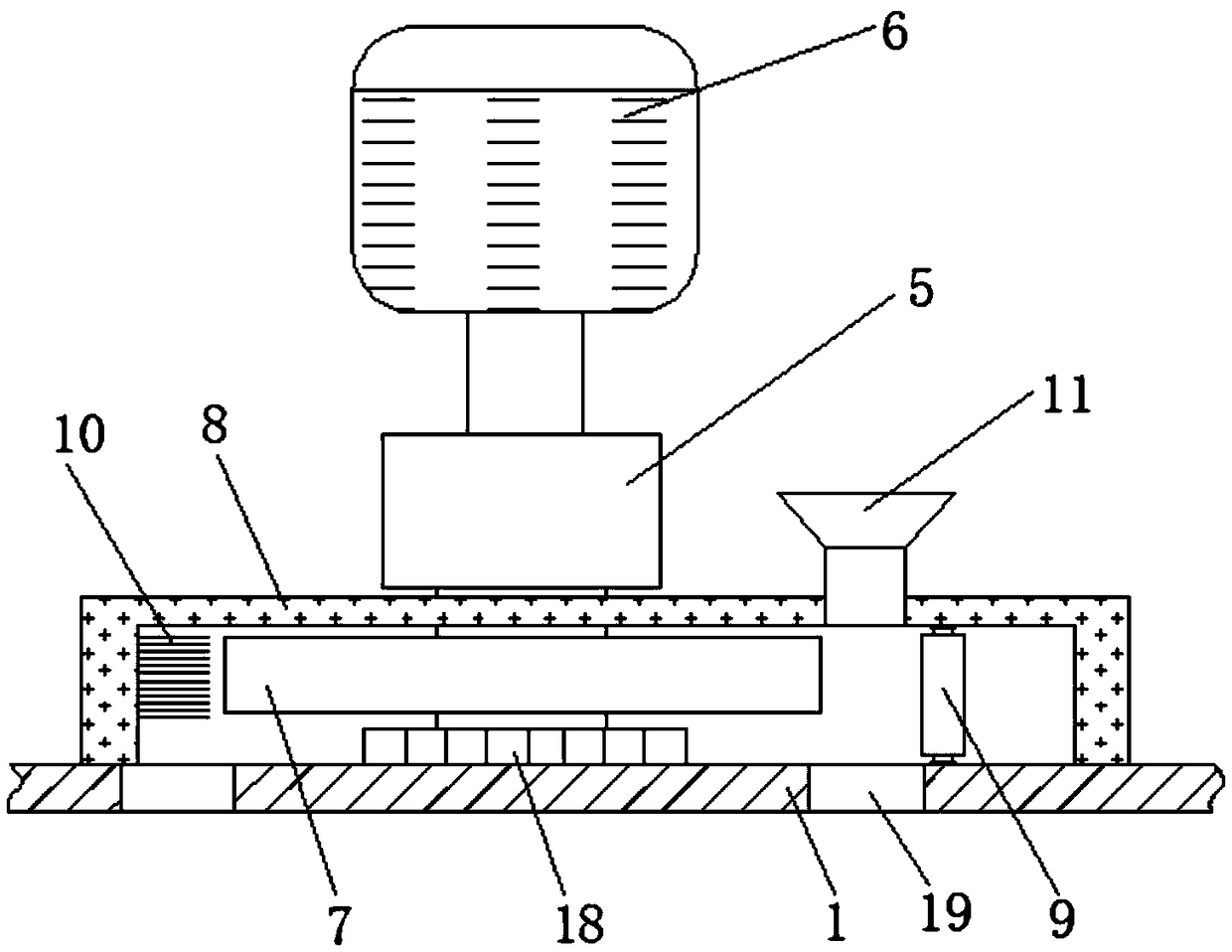

Medicine mixing device for biomedical research

InactiveCN108654511AReduce workloadEasy to observeRotary stirring mixersTransportation and packagingEngineeringMixing effect

The invention discloses a medicine mixing device for biomedical research. The medicine mixing device comprises a device body and a base, wherein the device body is mounted at the upper end of the base; a rotating shaft is mounted in the middle of the device body; stirring blades are arranged on the outer side of the rotating shaft; a motor is rotationally connected with the upper end of the rotating shaft; a grinding roller is arranged on the outer side of the rotating shaft; a protection shell is arranged at the upper end of the device body; a driven roller and a brush are arranged inside theprotection shell; an electromagnetic heater is mounted at the lower end of the device body; a temperature detector is arranged on a side surface of the device body; a measuring cylinder is arranged on the side surface of the device body; a liquid outlet is formed in the upper end of the measuring cylinder; the lower end of the measuring cylinder is communicated with the device body through a guide tube; a valve is mounted inside the guide tube. The medicine mixing device is simple in structure, has functions of liquid medicine weighing and solid medicine grinding, is capable of alleviating working intensity, improving research mixing effects, meanwhile has a heating function, and is convenient to use.

Owner:广州塔莱生物科技有限责任公司

On-line glue heating device

ActiveCN104635802AReal-time temperature controlIncreased consistencyTemperatue controlProgrammable logic controllerEngineering

The invention discloses an on-line glue heating device. A heating component comprises a glue gun storage rack, a glue gun heating chamber, a small glue barrel heating chamber, a first aluminum block and a second aluminum block mounted in the glue gun heating chamber and a third aluminum block mounted in the small glue barrel heating chamber, and the first, second and third aluminum blocks are profiling aluminum blocks made of cast aluminium alloy; an electrical component comprises a first resistance-type heating tube, a second resistance-type heating tube, a third resistance-type heating tube, a PLC (programmable logic controller), a non-contact inductive temperature sensor, an electronic display screen and a power supply, and the PLC receives feedback information of temperature, monitored by the temperature sensor in real time, of the first, second and third aluminium blocks, processes the feedback information and then sends corresponding commands for respectively controlling the temperature of the first, second and third aluminum blocks to be at a set value constantly in real time. Multiple small glue barrels and a glue gun can be heated on line at the same time, glue in the small glue barrels and the glue gun can be avoided being gradually increased in coagulation consistency when used in the station and can be used continuously without being heated repeatedly, heating temperature can be controlled to be consistent in real time, and technological requirements of gluing operation are met.

Owner:CHERY AUTOMOBILE CO LTD

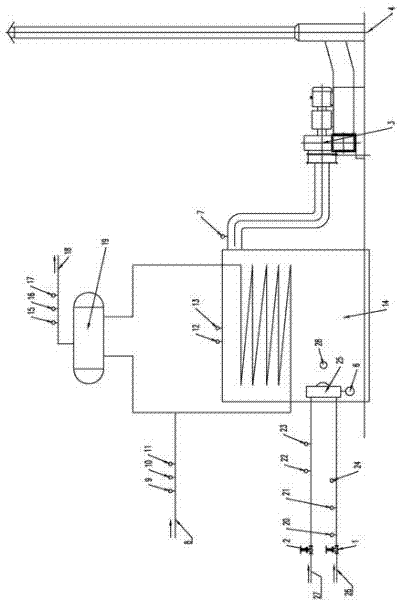

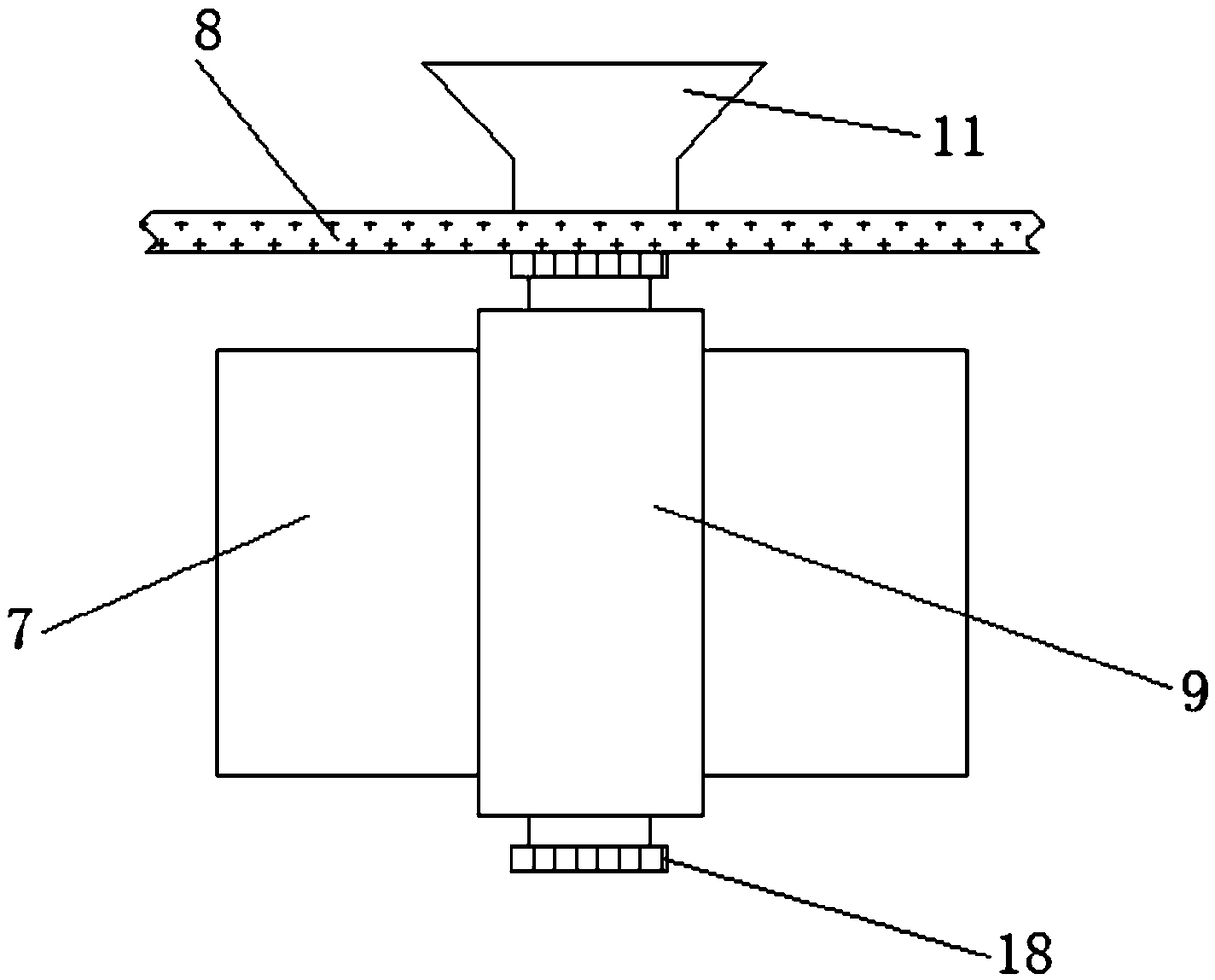

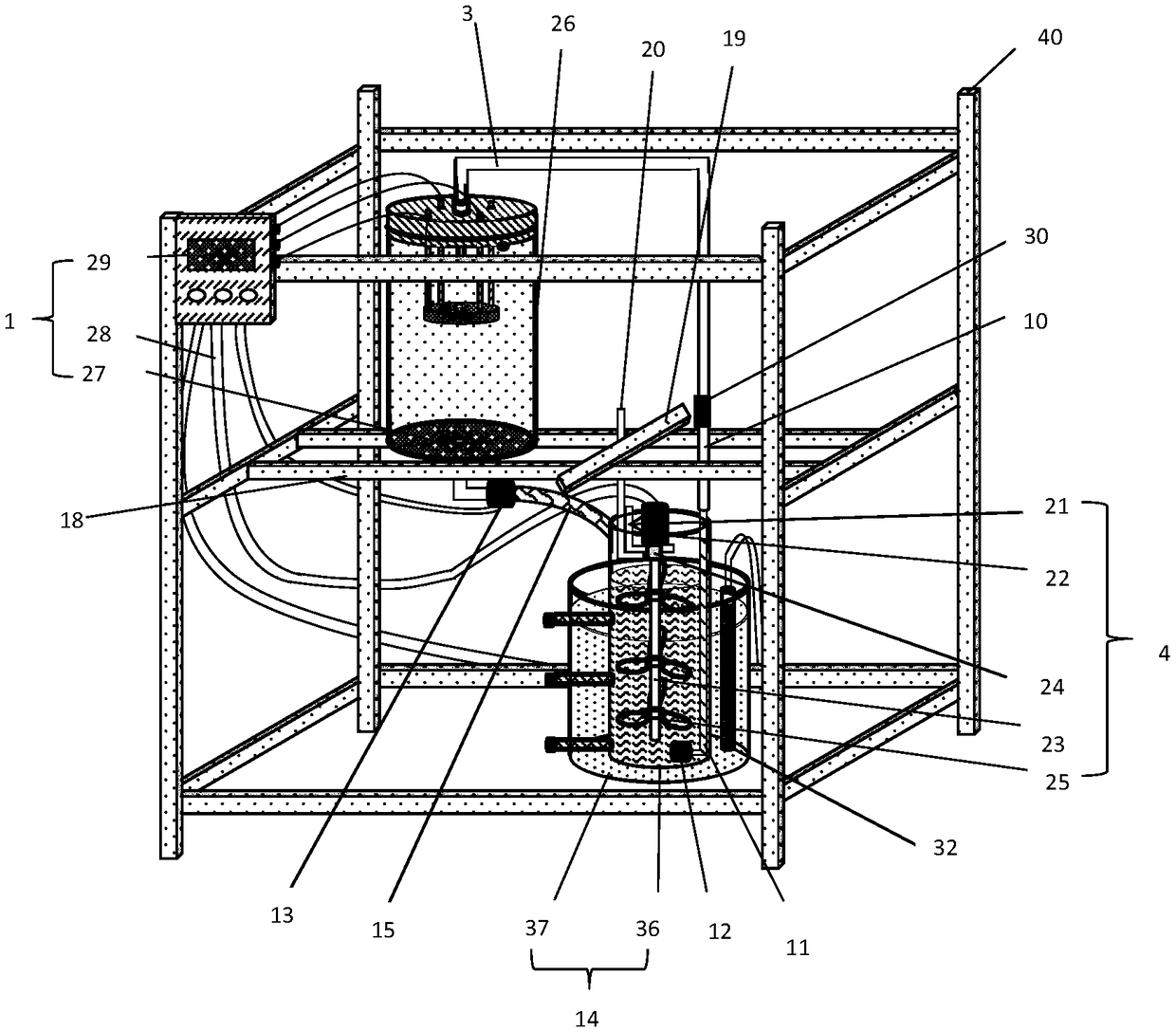

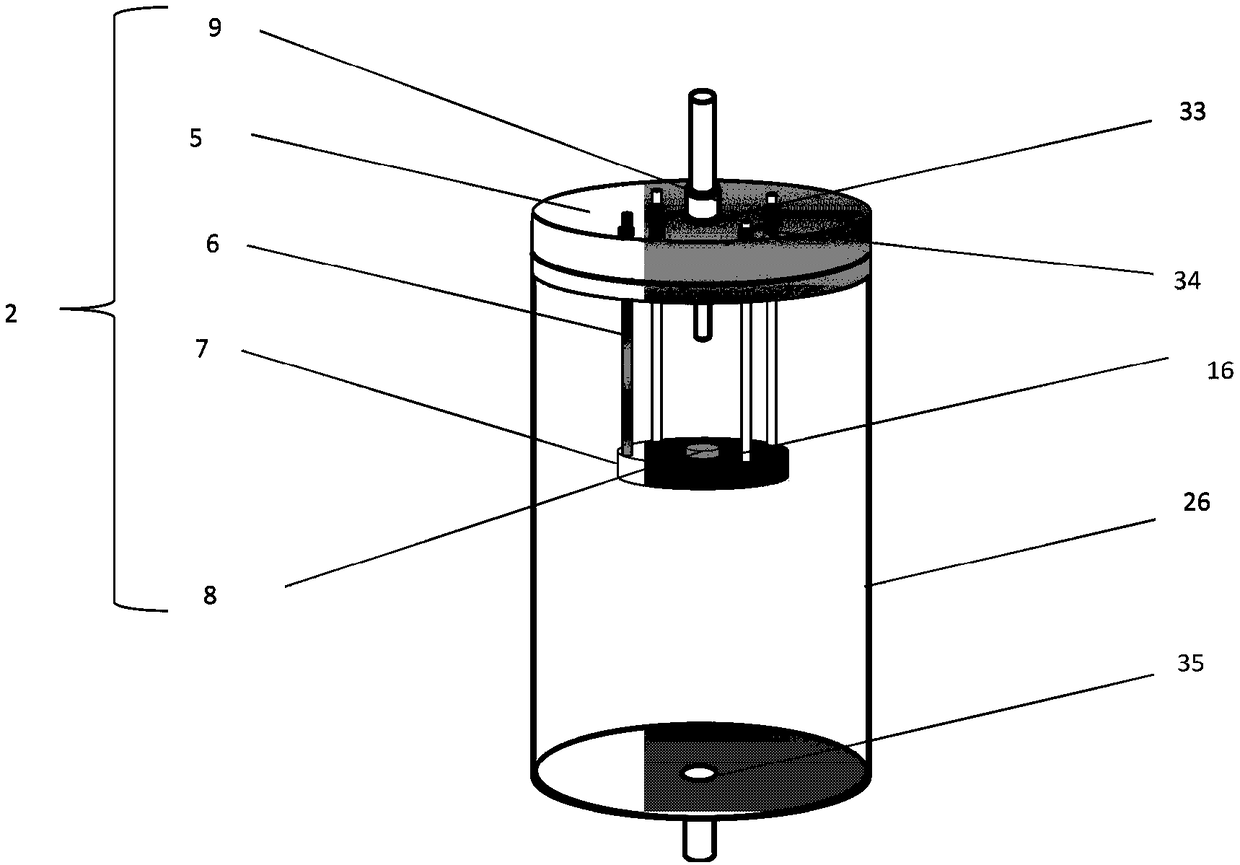

Intelligent cyclic flowing type erosion corrosion testing system and testing method

PendingCN109490124AImprove securityImprove efficiencyWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceTemperature controlControl system

The invention discloses an intelligent cyclic flowing type erosion corrosion testing system and testing method. The system comprises a temperature control system, a test piece erosion corrosion system, a test solution circulating system and a test solution stirring system. The test piece erosion corrosion system comprises a rubber plug, a tower connector, a connecting shaft rod, a test piece platform and a test piece and is mounted between the top and the bottom of a cylindrical test piece tank. One end of a pipeline is connected with the rubber plug while the other end is connected with one end of an upper corrugated pipe, the other end of the upper corrugated pipe is connected with a water pump, and one end of a lower corrugated pipe is connected with the rubber plug while the other endextends into a stirring tank to form the test solution circulating system. A third guide rail is connected with a motor angle part which is connected with a motor, and one end of an extension shaft isconnected with one end of the motor through a coupler while the other end extends into a test solution tank to form the test solution stirring system. The temperature control system comprises three groups of thermocouples, a control circuit and wires. Test piece flushing under different operating conditions is realized, and testing precision is improved.

Owner:ZHEJIANG SCI-TECH UNIV

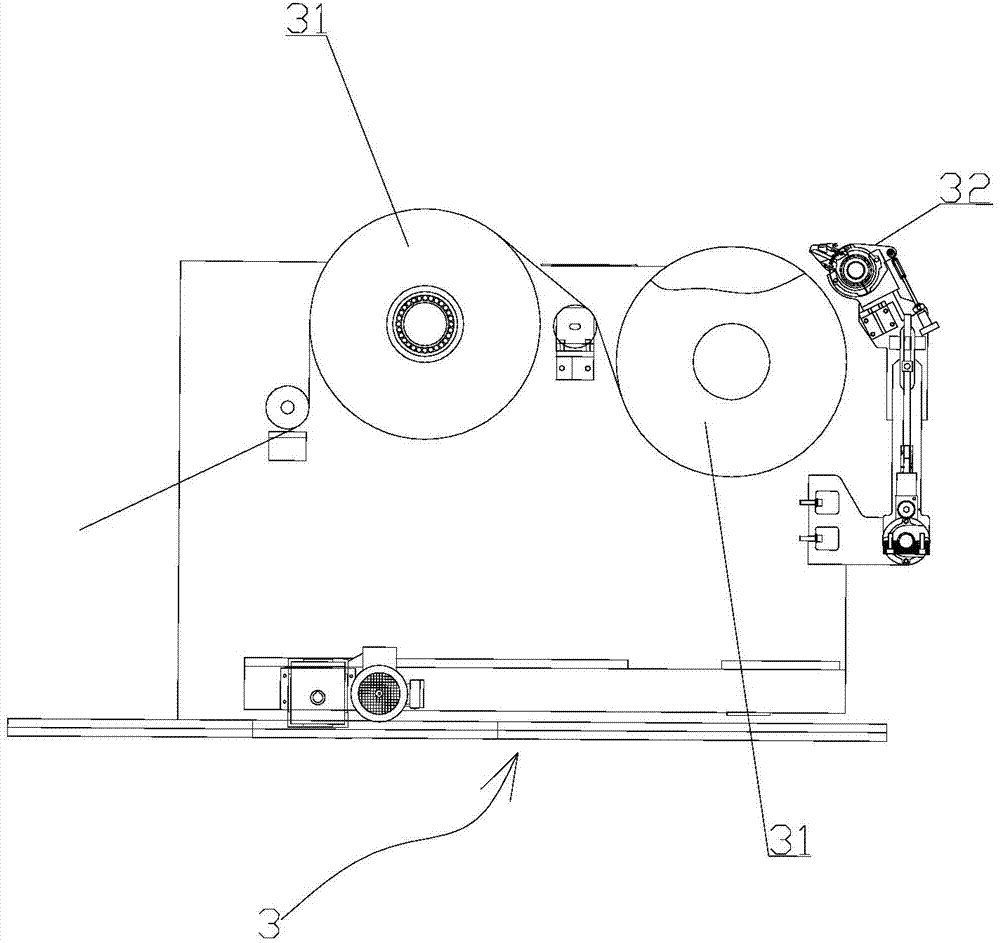

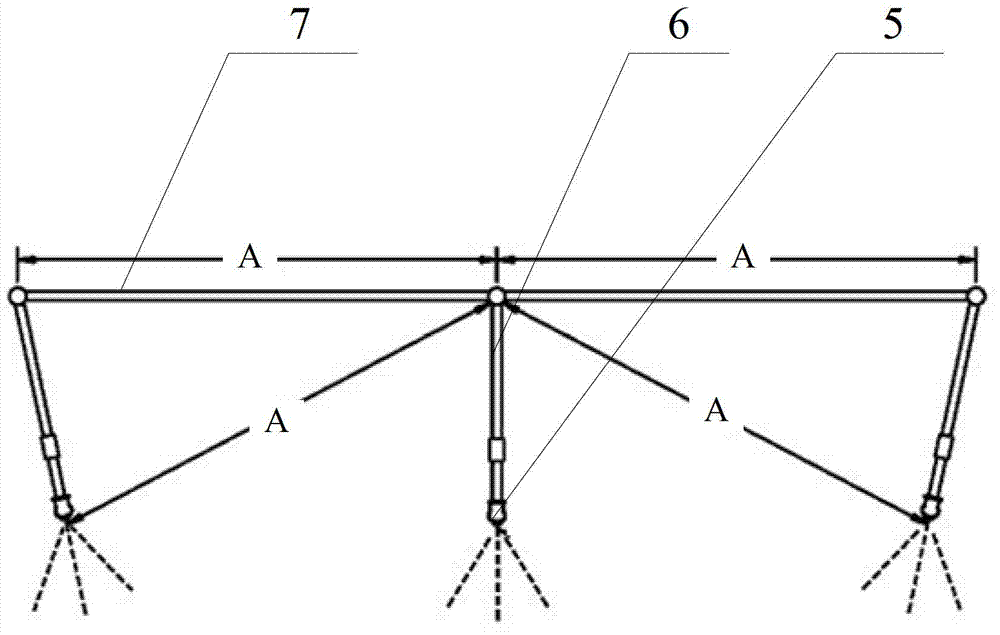

Auxiliary air-cooled wire drawing machine

The invention provides an auxiliary air-cooled wire drawing machine and belongs to the field of wire drawing machines. For an existing wire drawing machine, especially for a water tank wire drawing machine adopting the spraying manner on the aspect of cooling, the defect that temperature adjustment cannot be achieved in a wire drawing box exits, the auxiliary air-cooled wire drawing machine is provided and aims at overcome the defect. According to the auxiliary air-cooled wire drawing machine, improvement is conducted based on the prior art, the auxiliary air-cooled wire drawing machine comprises a wire drawing box, an unwinding mechanism and a winding mechanism. Tower wheels and wire drawing molds between the tower wheels are arranged in the wire drawing box. A spray pipe is horizontally arranged over the tower wheels and the wire drawing molds. Multiple spray heads perpendicular to the spray pipe are arranged outwards. A liquid storage box is arranged at the bottom of the wire drawing box. A temperature sensor is arranged in the liquid storage box and connected with a PLC arranged outside the wire drawing box. The PLC is connected with a fan on one side of the wire drawing box. By the adoption of the auxiliary air-cooled wire drawing machine, the temperature in the wire drawing box can be adjusted in real time through auxiliary fans, and the abnormal working conditions are prevented.

Owner:ANHUI JIANGNAN MINGFANG ELECTRONICS TECH

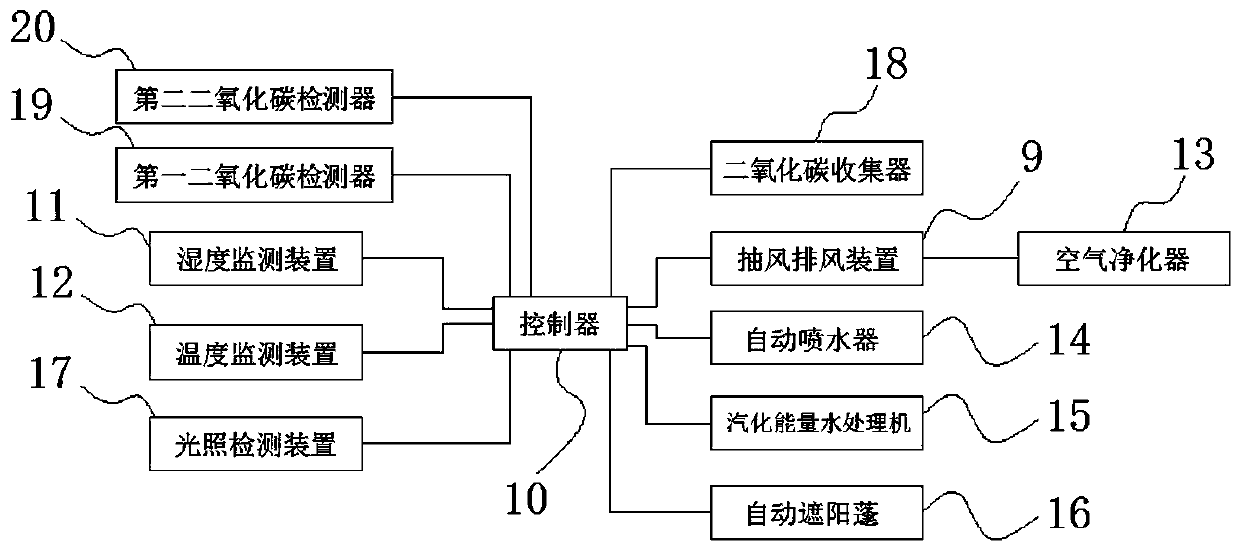

Container-type comprehensive ecological farm

InactiveCN110754413AEasy to solveIncrease water and fertilizerPisciculture and aquariaAgriculture gas emission reductionAnimal sciencePoultry farmer

The invention relates to a container-type comprehensive ecological farm, which comprises a container body; a channel which is arranged in the container body in its length direction and penetrates twoends of the container body; one side of the channel is provided with a fish box for farming fish, and the upper end of the fish box is provided with a culture medium; one end of the fish box is provided with a circulating water processor, and one end, far away from the fish box, of the circulating water processor is provided with a hydroponic device; the circulating water processor is communicatedwith the fish box and the hydroponic device, and conveys water from the fish box into the hydroponic device; the other side of the channel is provided with a control chamber and a storage chamber, the control chamber is arranged at one end of the storage chamber, the other end of the storage chamber is provided with a planting bed for planting vegetables, melons and fruits, one end, far away fromthe storage chamber, of the planting bed is provided with an earthworm farming box, and the upper end of the earthworm farming box is provided with a poultry farming box for farming poultry. Comparedwith the prior art, the container-type comprehensive ecological farm has the advantages that the size is small, the influence from plant diseases and insect pests is reduced, the ecological cycle utilization rate is high, and fresh and safe organic foods are provided.

Owner:苏朝鹏

Energy-saving constant temperature automatic control method and device for movable grate boiler

InactiveCN102278821APrecise temperature controlAccurately control supplyFluid heatersBoiler controlFurnace temperatureAutomatic control

The invention relates to an energy-saving and constant-temperature automatic control method and device for a movable grate boiler, belonging to the field of boilers. Using heat carrier temperature parameters, furnace temperature parameters, furnace negative pressure parameters, furnace flue gas component content parameters, heat carrier flow parameters and heat carrier pressure parameters, through software analysis and expert database reasoning calculations, the fuel supply and combustion air volume can be determined in real time And the optimal data of the furnace negative pressure, real-time control of the operating speed of the movable grate of the boiler supplying fuel, the speed of the fan motor, and the speed of the wind-inducing motor, and then real-time control of the fuel supply, combustion air volume, and furnace negative pressure. The method and system of the present invention can accurately control the fuel supply, combustion-supporting air volume, and furnace negative pressure in real time during the combustion process, while accurately controlling the temperature of the output heat carrier, saving fuel and electric energy, and achieving the goals of energy saving, emission reduction, and consumption reduction .

Owner:威海宝源电气有限公司

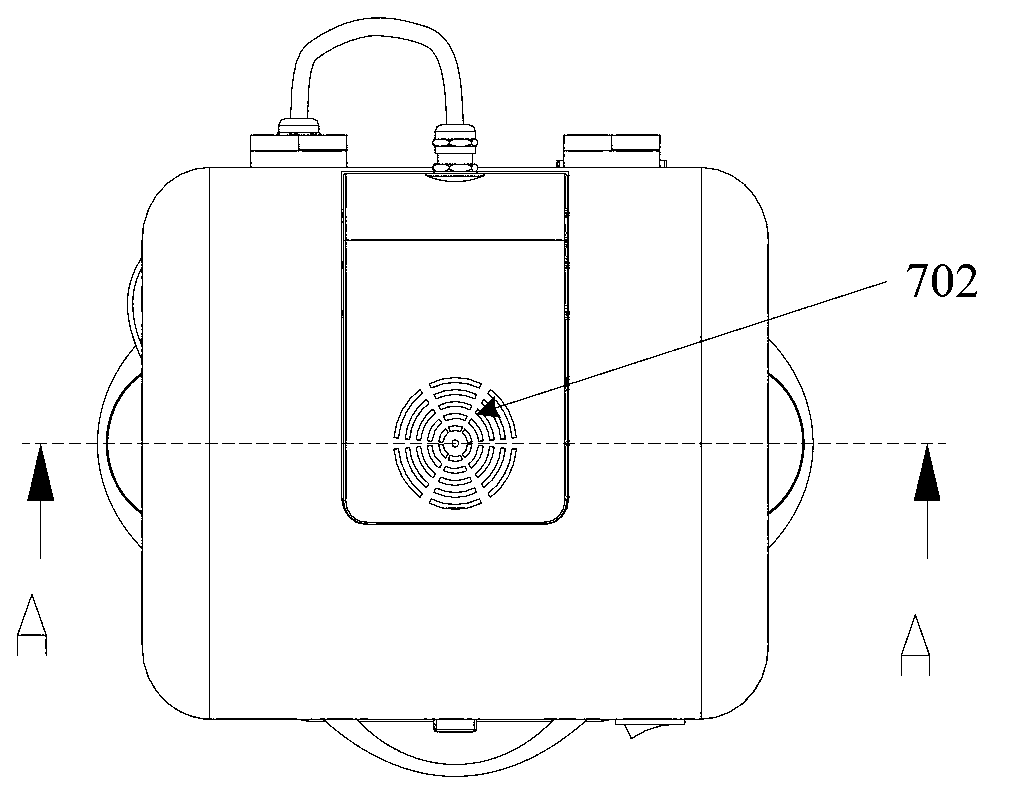

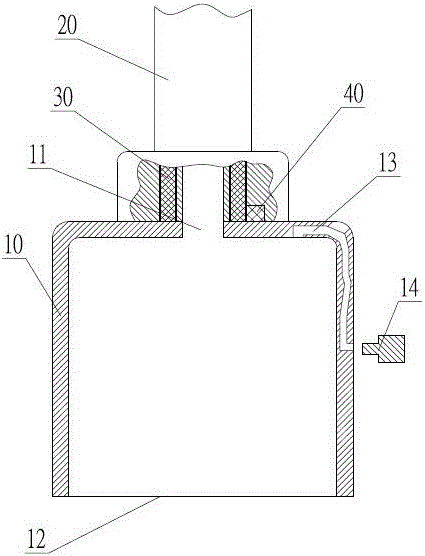

Constant-temperature constant-pressure adjustable cupping cup

PendingCN106512114AReal-time temperature controlPressure real-time controlPneumatic massageMedical devicesFresh airEngineering

The invention discloses a constant-temperature constant-pressure adjustable cupping cup, which at least comprises a cup body, a vacuum pump and a main control unit. A heating device and temperature sensors are arranged on the cup body, and the heating device and the temperature sensors are connected with the main control unit, so that the goals of controlling the temperature in the cup body in real time and maintaining the temperature in the cup body in the constant-temperature state can be achieved; a throttle valve, a pressure relief valve and pressure sensors are arranged on a pipeline formed between the cup body and the vacuum pump, and the vacuum pump, the throttle valve, the pressure relief valve and the pressure sensors are connected with the main control unit, so that the goals of controlling the pressure in the cup body in real time and maintaining the pressure in the cup body in the constant pressure state can be achieved; an air exchange passage communicating with the outside is arranged on the cup body, so that external fresh air can be supplemented into the cup body at any time in the cupping process; and the air flow speed of the air exchange passage is smaller than the air suction speed of the vacuum pump, so that the inside of the cup body is enabled to be maintained in the relatively stable negative pressure state under the continuous work state of the vacuum pump.

Owner:GUANGZHOU INFUMEDI MEDICAL TECH CO LTD

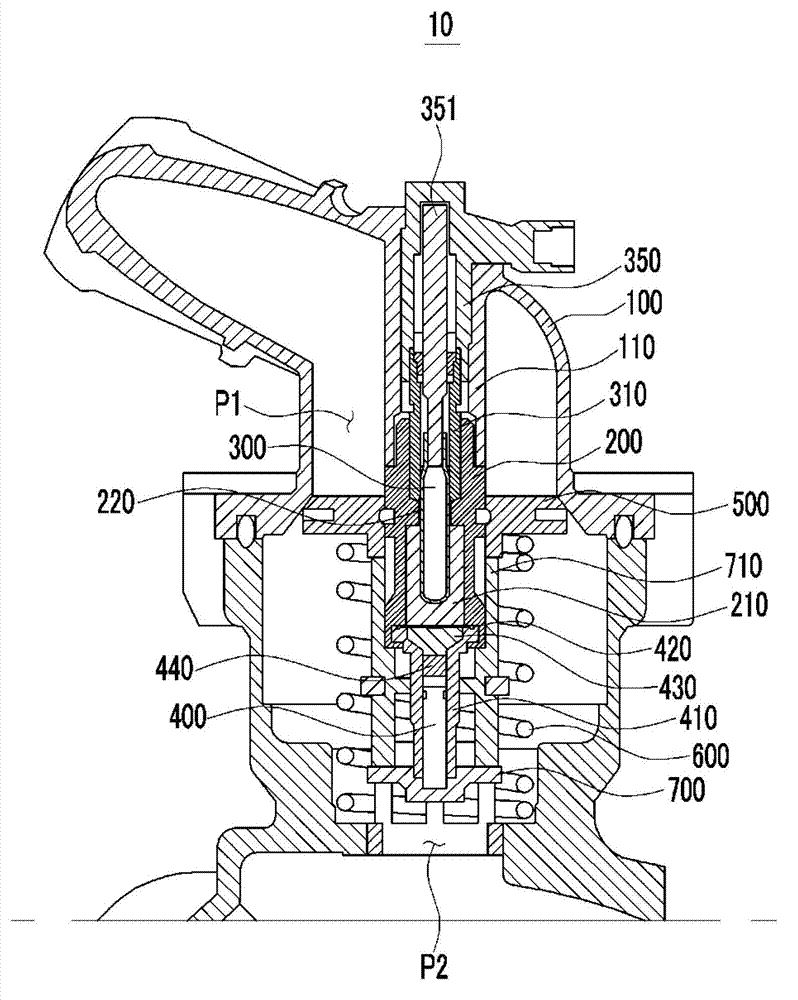

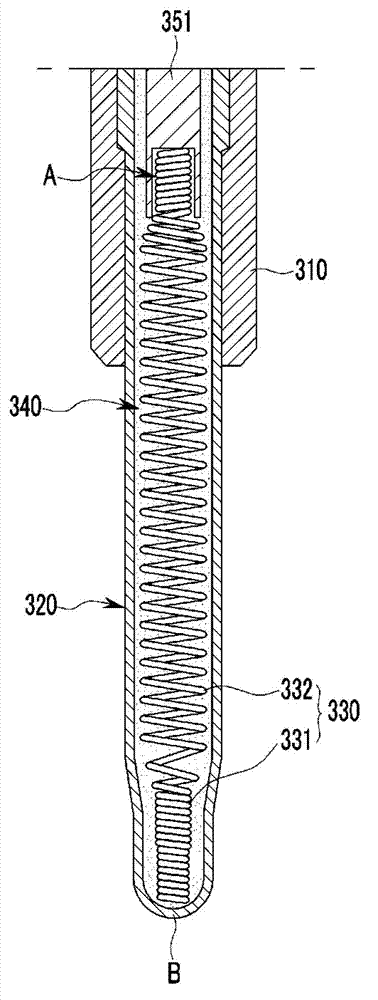

An electronic thermostat apparatus

InactiveCN103362626AReal-time temperature controlImprove fuel efficiencyOperating means/releasing devices for valvesCoolant flow controlElectricityEngineering

Owner:HYUNDAI MOTOR CO LTD +2

Temperature-adjustable microorganism culture device and method

InactiveCN112143638AEasy to fixReal-time monitoring of environmental informationBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyMicroorganism

The invention discloses a temperature-adjustable microorganism culture device and method, and relates to the technical field of microorganism culture. The device comprises a culture box, a base and aculture dish, wherein the bottom of an inner cavity of the culture box is fixedly connected with the bottom of the base, the top of the base makes contact with the bottom of the culture dish, a driving box penetrates through the top of the culture box, the top of an inner cavity of the driving box is fixedly connected with a motor through a supporting plate, and the output end of the motor is fixedly connected with a threaded rod through a coupler. According to the temperature-adjustable microorganism culture device and method, external air can be prevented from directly entering the culture box, so that bacteria in the air are unlikely to pollute a culture medium in the culture box; and moreover, manual operation is not needed when a culture solution or water needs to be added, the overall culture effect is good, the culture dish can be well fixed, and the temperature in the culture box can be controlled in real time.

Owner:JIAMUSI UNIVERSITY

Spraying testing device

ActiveCN102854442AReal-time temperature controlReduced replacement timesTesting dielectric strengthTemperature controlWater storage tank

The invention discloses a spraying testing device which comprises a groove-shaped working table, a water storage tank and a spraying system, wherein the water storage tank is communicated with the groove-shaped working table; the spraying system is used for spraying water and is communicated with the water storage tank; a temperature control device is arranged inside the water storage tank; the spraying system is provided with a power pump; the temperature of the spraying water is 25 DEG C; the resistance of the spraying water is 3500+ / -175omega cm; when the spraying testing device is used, the temperature of the spraying water is 25 DEG C and the resistance of the spraying water is 3500+ / -175omega.cm, so that the requirements in UL (Underwriters Laboratories) standards are completely met, the actual situation of rainwater is simulated well; and meanwhile the spraying water flows into the water storage tank after being sprayed to a battery panel put in the groove-shaped working table, and is sucked into the spraying system by the power pump, thereby a circulation system is formed; the spraying water which meets the standards can be used in circulation, so that the production cost is reduced; and meanwhile the temperature control can be carried out; and by adoption of the spraying testing device provided by the invention, the spraying test to the battery panel can be accomplished well.

Owner:YINGLI GRP

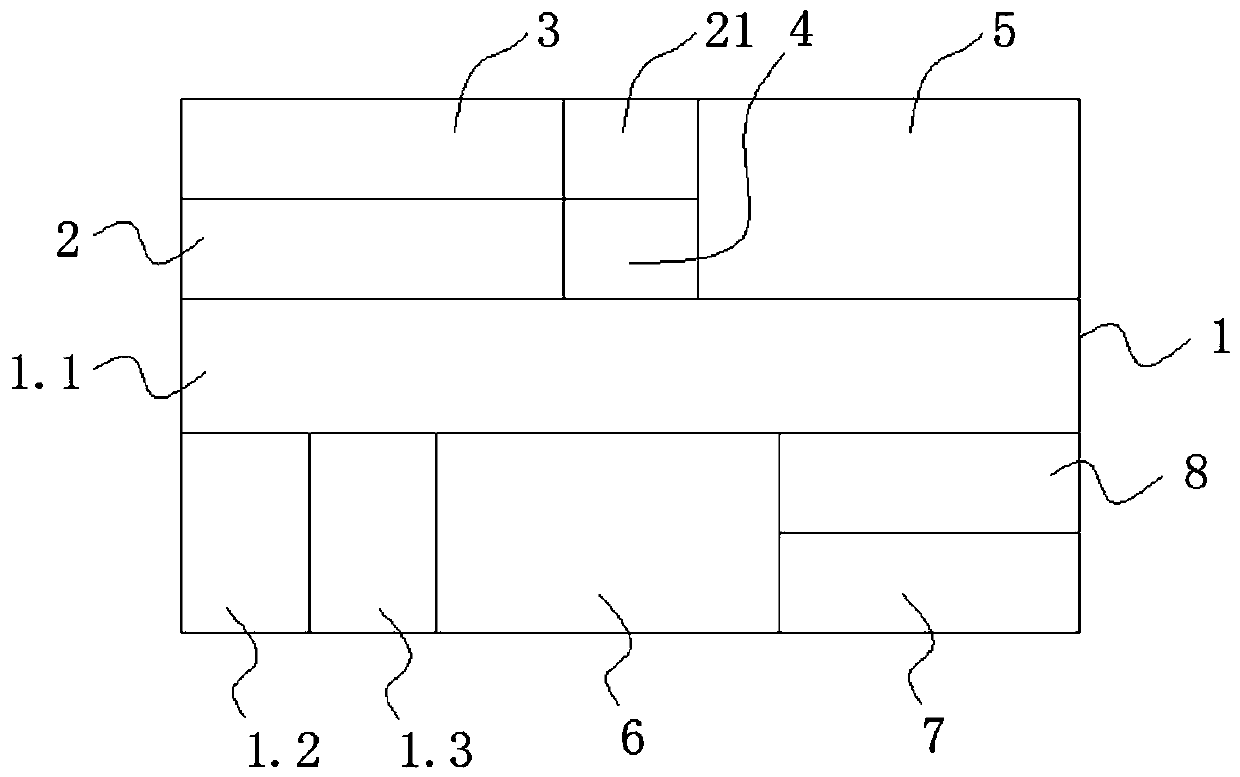

Cushion with switchable bearing parts and switching control method

PendingCN106937809APrevent outflowUniform changeStuffed mattressesSpring mattressesEngineeringCushion

The invention relates to a cushion with switchable bearing parts and a switching control method. The temperature of conventional cushions with switchable bearing parts cannot be uniformly controlled. The cushion with switchable bearing parts in the invention comprises a cushion (42); the cushion is connected with a control unit (40) via a pipeline; the control unit is connected with a medium box (16) via a pipeline; the cushion comprises a base plate (2); the base plate is provided with an inlet-and-outlet pipe A (6) and an inlet-and-outlet pipe B (7); the inlet-and-outlet pipe A is communicated with coating films on or lining capsules of a group of grooves A (3) to form a cavity; the inlet-and-outlet pipe B is communicated with coating films on or lining capsules of a group of grooves B (4) to form another cavity; and the soft films on the grooves are separately connected with the ends of the grooves A and the grooves B. The invention discloses the cushion with switchable bearing parts and the switching control method.

Owner:HARBIN ZIRAN TECH DEV CO LTD

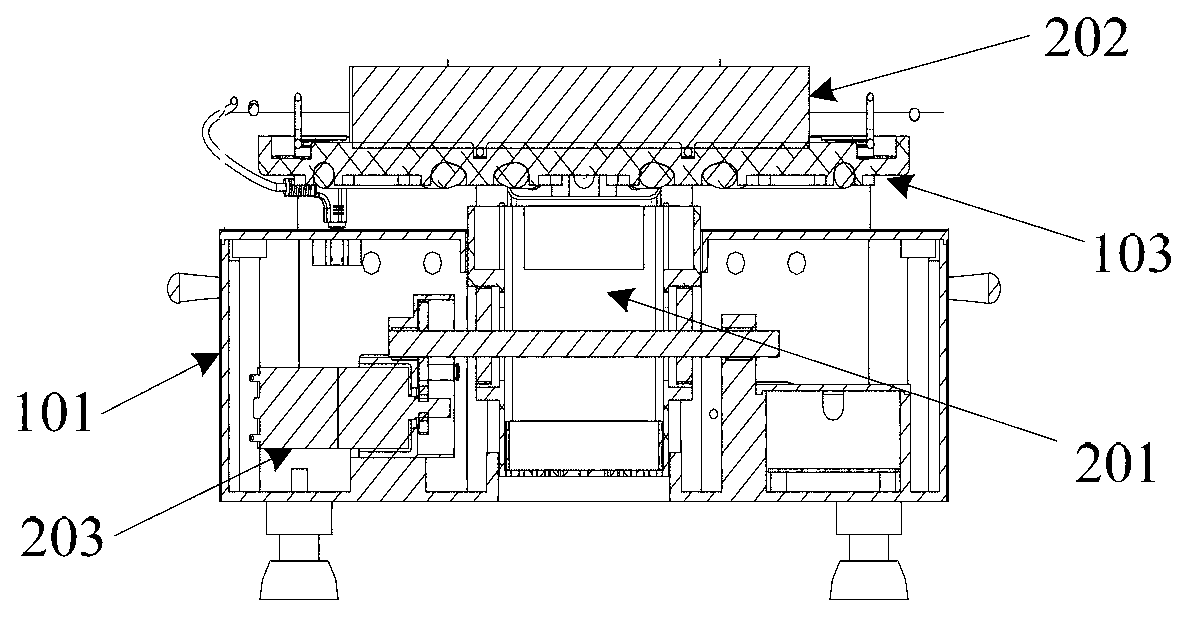

Cooling device and method for submarine motor

InactiveCN110858745AGuaranteed cooling effectAdaptableCooling/ventillation arrangementThermodynamicsElectric machine

The invention provides a cooling device for a submarine motor, which comprises a motor, a compensator, a cooler and a control system, wherein the motor comprises a motor housing, one end of the motoris connected with a pump group, and the other end of the motor is connected with an electric control variable pump; the compensator is used for compensating seawater pressure and is connected with theelectric control variable pump; the cooler is used for carrying out heat exchange on cooling liquid of the motor and seawater, and the cooler is communicated with the motor housing; the control system is connected with the electric control variable pump and the compensator and used for controlling and adjusting heat dissipation of the motor; and the cooler is communicated with the compensator, sothat the circulating flow of the cooling liquid is realized to cool the motor. The invention further provides a cooling method for the submarine motor. The cooling method uses the above cooling device for cooling.

Owner:上海中车艾森迪海洋装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com