Power stable solid laser and control method

A solid-state laser, power stable technology, applied in the field of lasers, can solve the problems of low temperature control accuracy, affecting the working current, low accuracy, etc., to achieve the effect of improving power stability, avoiding hysteresis and error, and accurately controlling temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

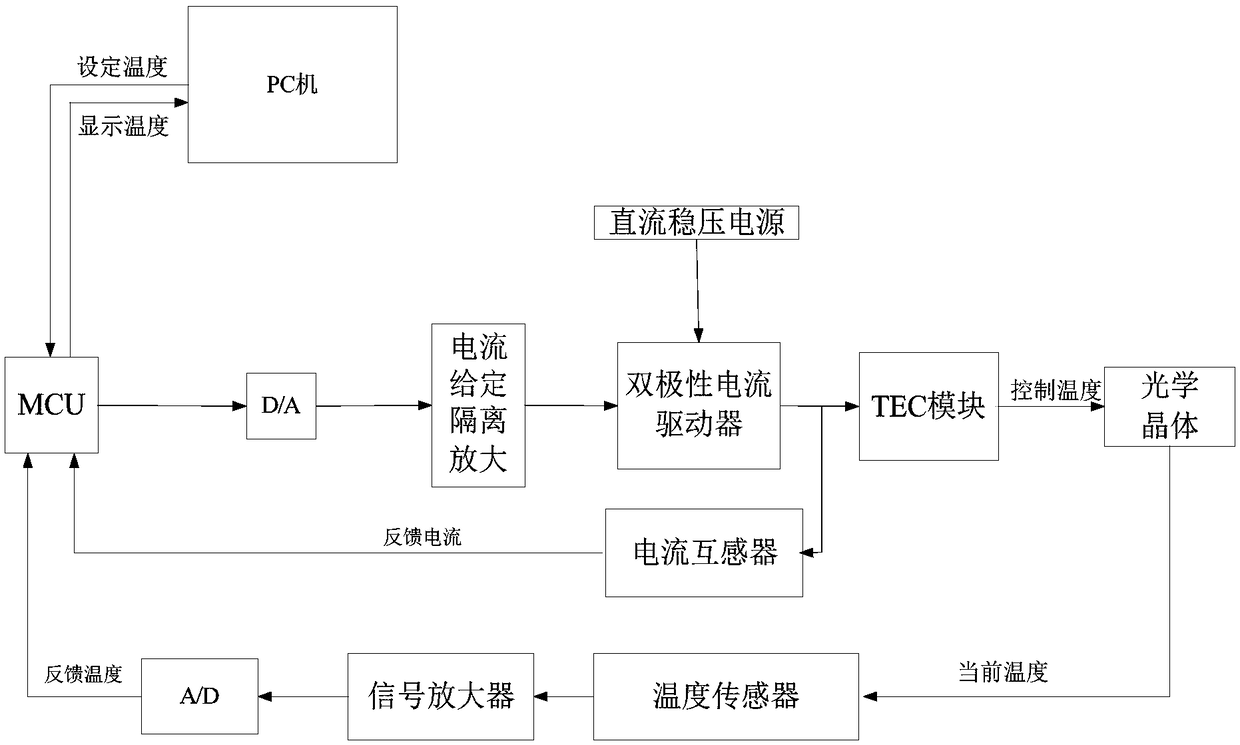

[0029] The power stable solid-state laser of the present invention includes a base for circulating cooling water therein, a heat-conducting carrier for installing and fixing the optical crystal of the solid-state laser, a temperature sensor arranged in the heat-conducting carrier, and a heat-conducting carrier between the seat and the base and is driven by a bipolar current, such as the semiconductor refrigeration unit driven by the semiconductor refrigeration chip such as the H bridge, and the control unit, wherein the control unit includes a communication connection with the temperature sensor A microprocessor, a current transformer used to collect the output of the bipolar current driver, and the controller is controllably connected to the bipolar current driver.

[0030] Among them, the temperature sensor for measuring and controlling the temperature of the optical crystal, such as a platinum resistance sensor and a TEC semiconductor refrigeration unit, is installed on a th...

Embodiment 2

[0033]Wherein, the temperature sensor includes a temperature sensing unit, an armored screw is formed for positioning the hollow cavity of the temperature sensing unit, and the armored screw is threadedly connected with the heat conduction carrier. Described temperature sensor is thermal resistance sensor, and described thermal resistance sensor is connected to microprocessor after signal amplifier and A / D module, and the output of described microprocessor passes D / A module and current given isolation amplifier Connect to the bipolar current driver as described. The current on the thermal resistance sensor changes linearly with the ambient temperature value, and the collected current signal is converted into a voltage signal. Since the collected voltage signal is at the millivolt level, it is first amplified by the preamplifier under the control of the single-chip microcomputer, and then passed through The multi-channel analog conversion switch reaches the input terminal of th...

Embodiment 3

[0037] As one of the specific implementation manners, the microprocessor is a single-chip microcomputer, and also includes a human-computer interaction screen or a PC connected to the single-chip microcomputer in communication. The PC is responsible for the configuration and management of each unit, processing the processing results uploaded by the terminal, and recording the temperature changes in real time. Moreover, the control results are transmitted to the PC in real time through serial communication for recording, and the form of graphs is intuitively generated, and the experimental data can be converted and output in various formats at any time for further analysis and processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com