Energy-saving control method and system for air-source heat pump system

An air source heat pump, energy-saving control technology, applied in the direction of control input related to air characteristics, space heating and ventilation control input, heating mode, etc., can solve the problem of manual on-duty status, limited energy-saving potential, lack of professionalism, scientificity, etc. problem, to achieve the effect of overcoming the difficulty of control and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

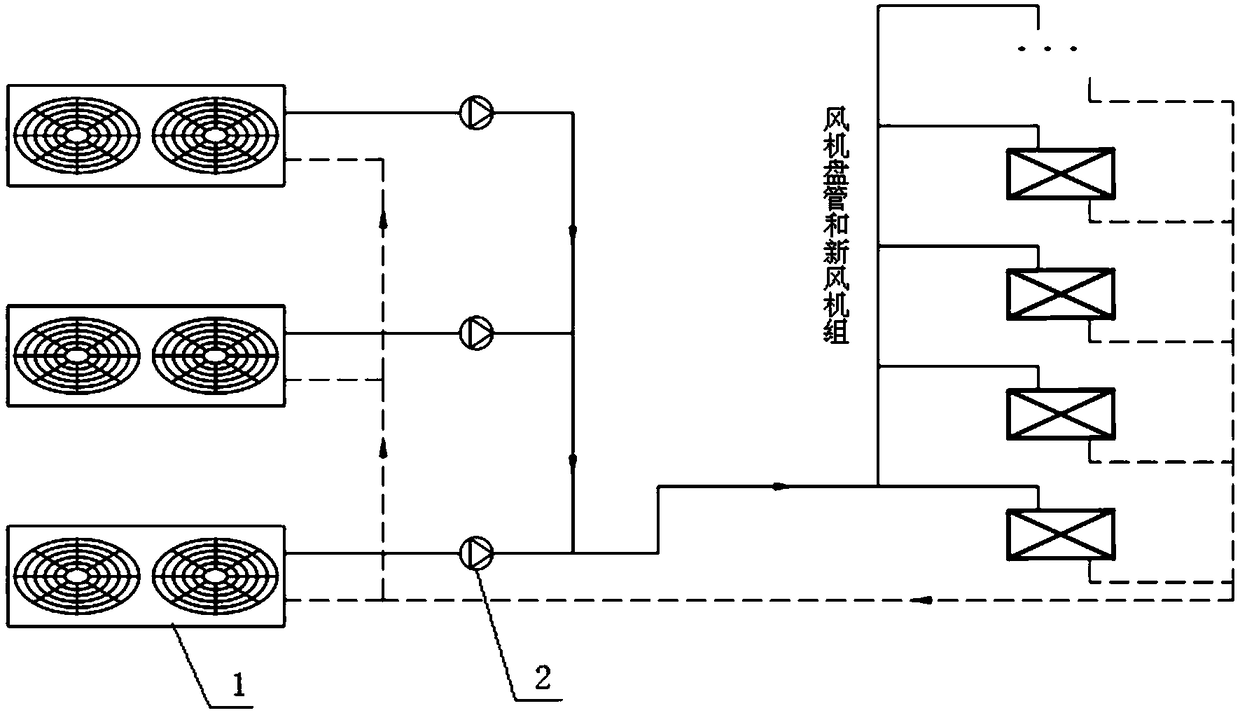

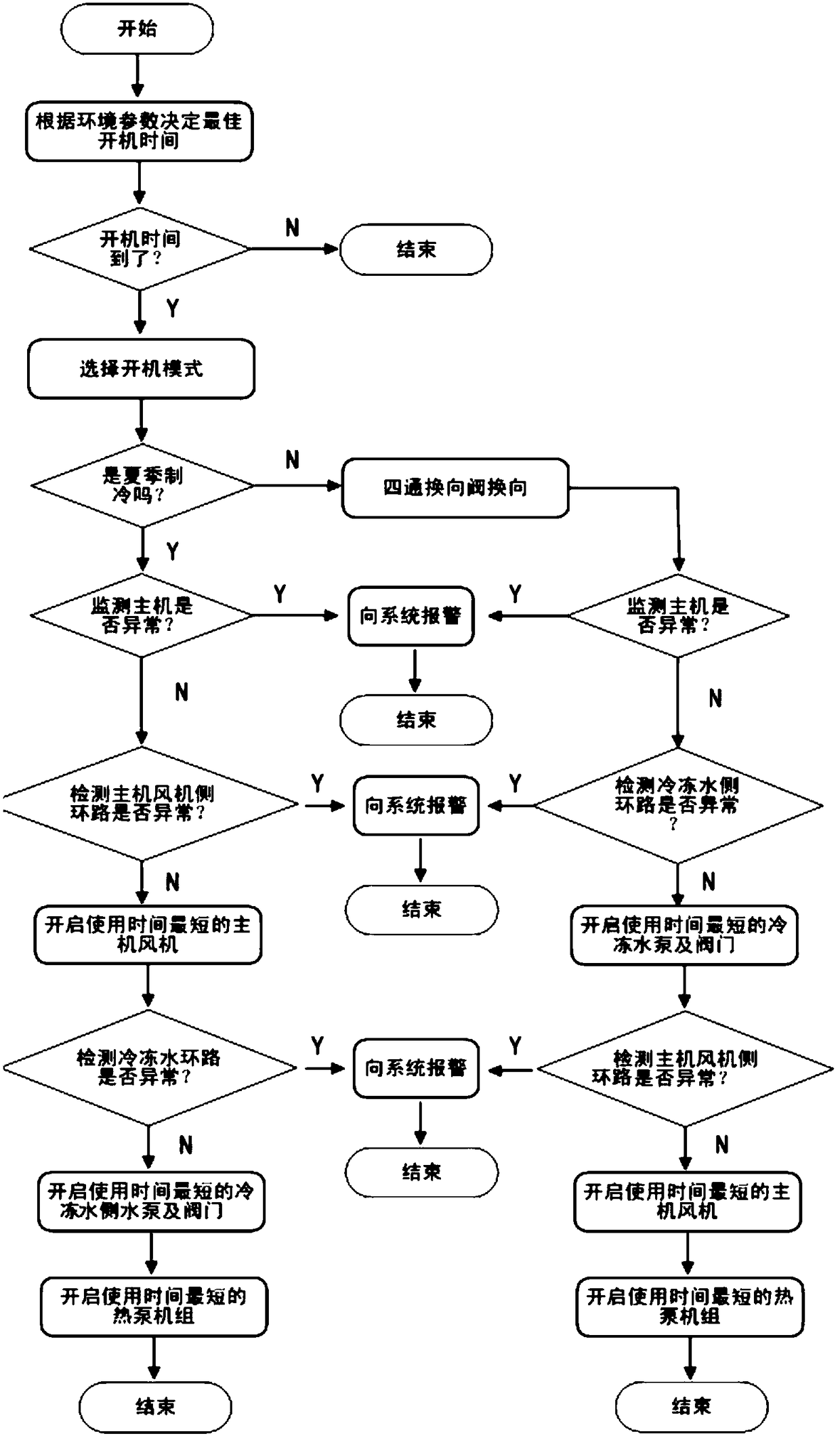

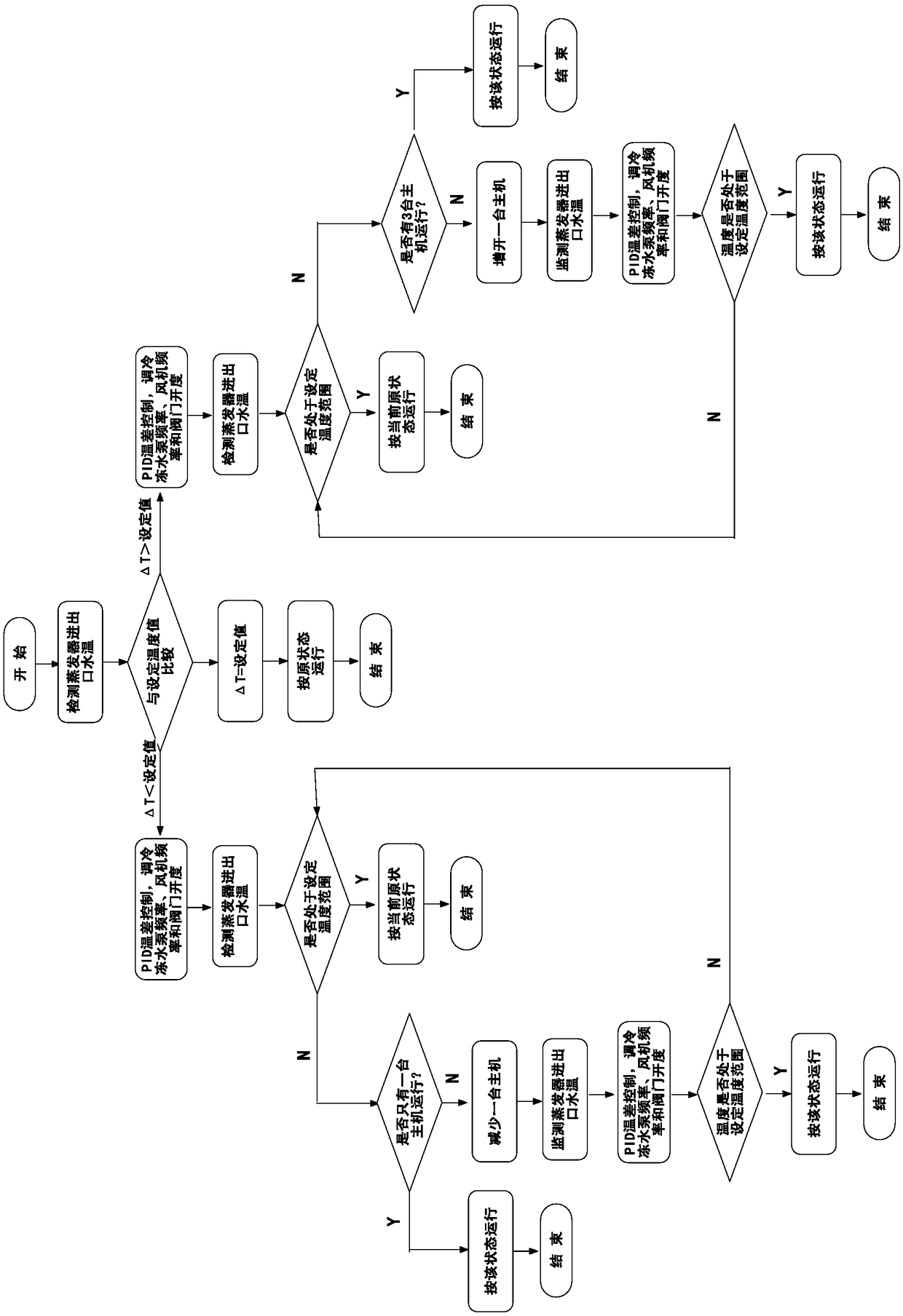

[0059] An energy-saving control of an air-source heat pump system includes three parts: a building standard cooling and heating load prediction model based on big data analysis and processing, building fine-grained zoning control, and three-stage start-stop control of air-conditioning equipment.

[0060] In the present invention, the building standard cooling and heating load prediction model, that is, the building standard cooling and heating energy consumption database, mainly includes the basic meteorological data of China's five major climate zones, and the original building data in the design stage (such as building functions, building shape coefficients, envelope structure parameters, Air-conditioning area, personnel usage and initial design parameters of building indoor environment, etc.), real-time data acquisition and storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com