Intelligent substation inspection method

An intelligent inspection and substation technology, applied in the field of substation inspection, can solve problems such as dependence, failure to detect hidden faults in time, and inability to adapt to the development of enterprise informatization, and achieve the effect of ensuring safe and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to better understand the present invention, the present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

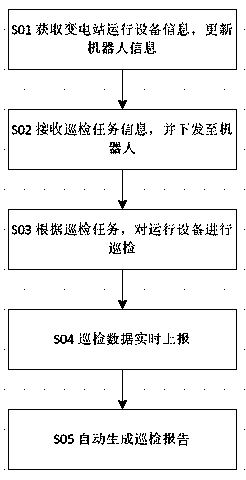

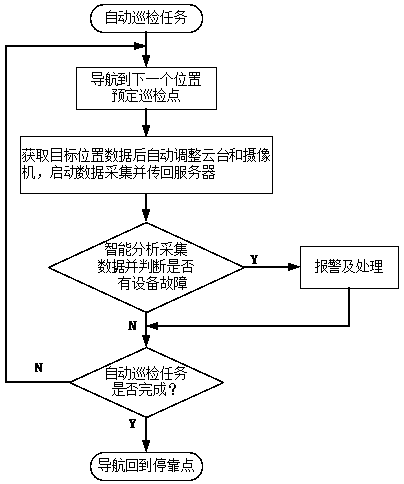

[0053] like figure 1 As shown, an intelligent inspection method for a substation includes the following steps:

[0054] S1: Establish a 3D model of the substation, and perform 3D video fusion display of the substation; including the following steps:

[0055] S11: Use aerial photography and laser scanning to construct a three-dimensional full-true inspection scene;

[0056] S12: Use video fusion technology to splice, register, correct and fuse the video data of surveillance cameras distributed in key surveillance areas; the details are as follows:

[0057] S121: The outdoor scene and the 3D scene are matched by aerial photography, and the geographical coordinates of the outdoor scene are converted into 3D space coordinates, the formula is as follows:

[0058] ;

[0059] in, is the converted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com