Auxiliary air-cooled wire drawing machine

A wire drawing machine and auxiliary air technology, applied in the field of wire drawing machines, can solve problems such as affecting the quality of wire drawing and not having the ability to control the temperature of the wire drawing box, and achieve the effect of consistent flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

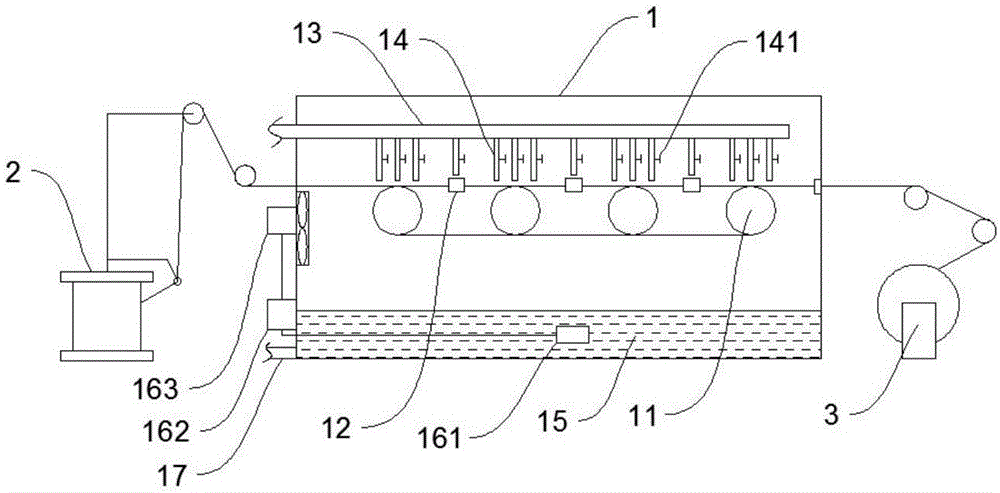

[0014] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] Such as figure 1 An auxiliary air-cooled wire drawing machine shown includes a wire drawing box 1, a wire-releasing mechanism 2 and a wire-receiving mechanism 3. The wire drawing box 1 is provided with a tower pulley 11, a wire drawing die 12 between the tower pulleys 11, and a tower pulley 11 A spray pipe 13 is arranged horizontally directly above the wire drawing die 12, a plurality of spray heads 14 are arranged vertically downwards with the spray pipe 13, a liquid storage tank 15 is provided at the bottom of the drawing box 1, and the liquid storage tank 15 is provided with a liquid outlet 17 A temperature sensor 161 is set in the liquid storage tank 15, and the temperature sensor 161 is connected to the PLC controller 162 arranged outside the drawing box 1, and the PLC controller 162 is connected to the fan 163 arranged on one side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com