Frying and roasting machine

A frying machine and frying technology, which is applied to frying pans, roasters/barbecue grids, kitchen utensils, etc., can solve the problems of not being able to adjust the frying state, unable to obtain high-quality grilled steaks with taste and flavor, etc. Achieving high-quality results that reduce adverse or health risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

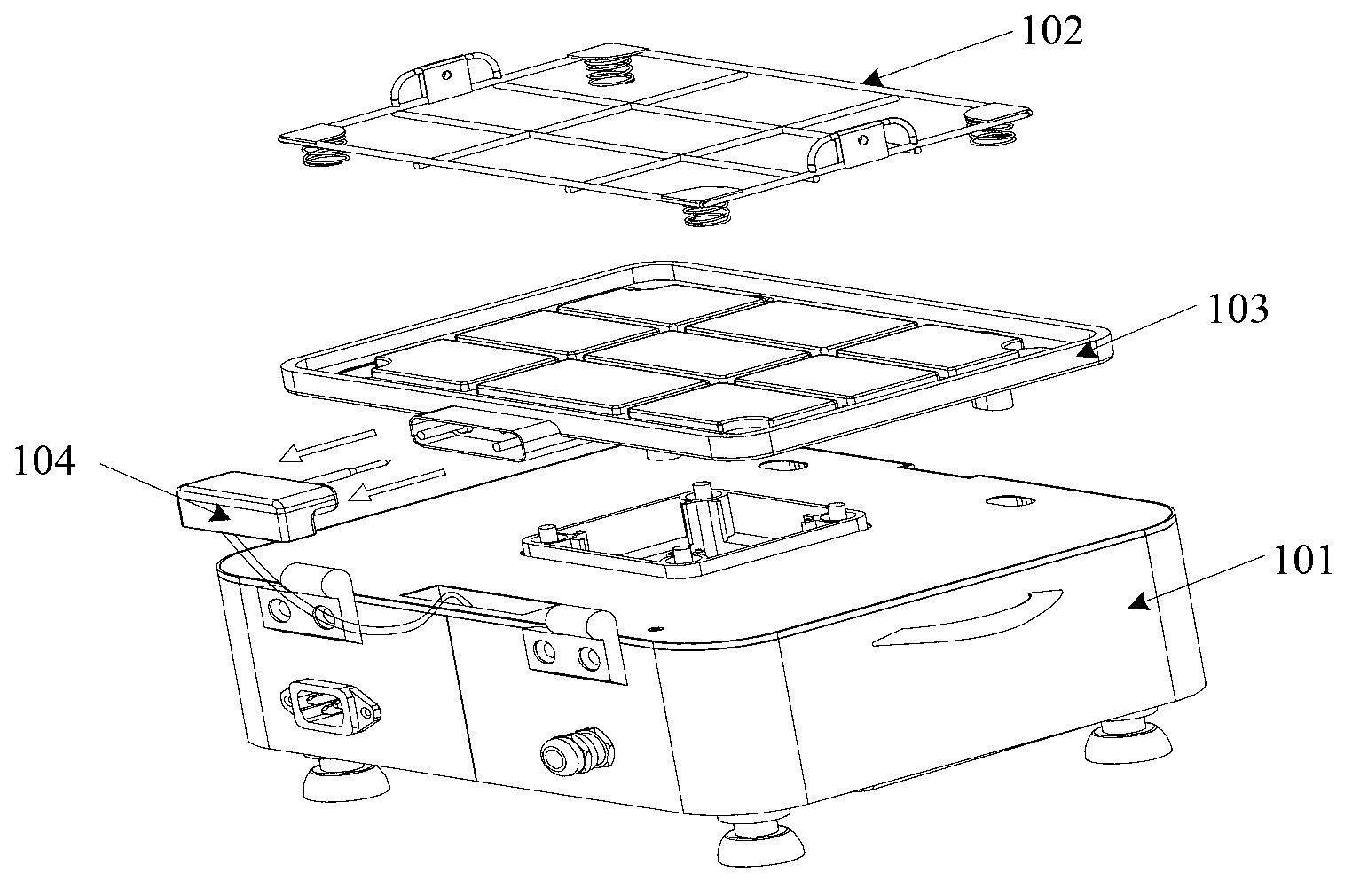

[0041] An embodiment of the present invention provides a grilling machine, including: a grill pan, a first heating plate, a first housing, a first sensor assembly, a second sensor assembly, and a controller;

[0042] The baking pan is installed on the first casing;

[0043] The first heating plate is located between the grill pan and the first casing;

[0044] The first sensor assembly is connected between the first heating plate and the controller, and is used to transmit the temperature of the first heating plate to the controller;

[0045] The second sensor assembly is connected to the controller, and is used to transmit the temperature of the grilled food to the controller;

[0046] The controller is connected with the first casing, and is used for adjusting the temperature of the first heating plate according to the current temperature of the first heating plate and the grilled food.

[0047] In the embodiment of the present invention, the first sensor assembly is fixed...

Embodiment 2

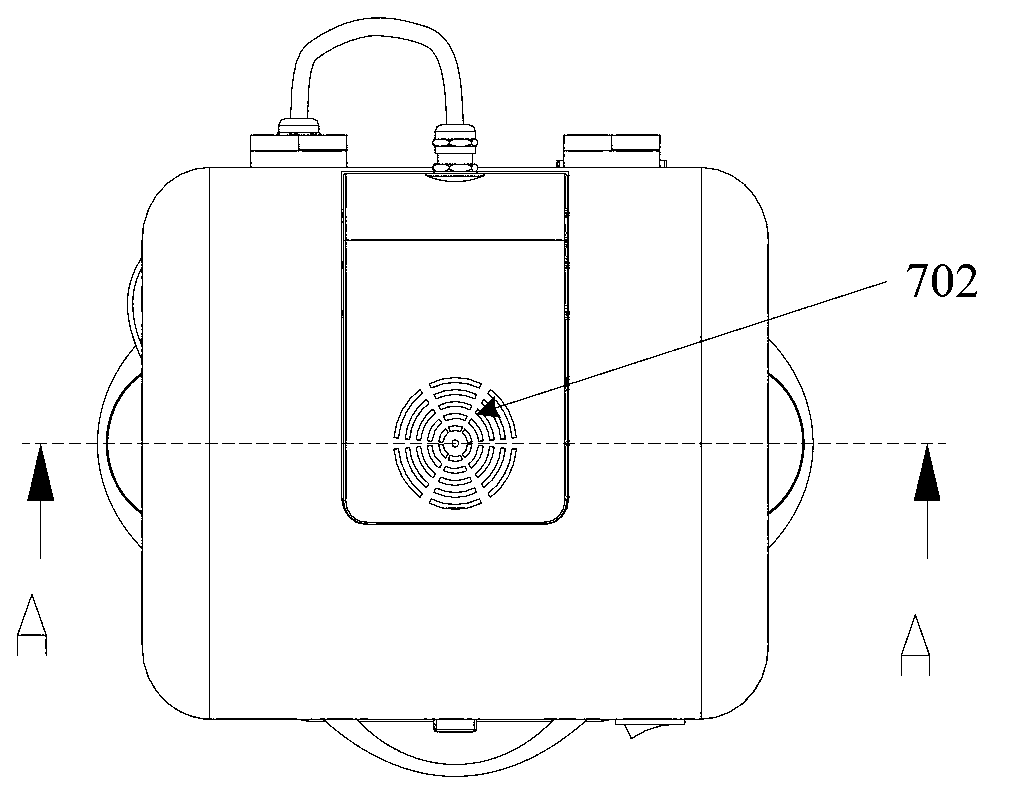

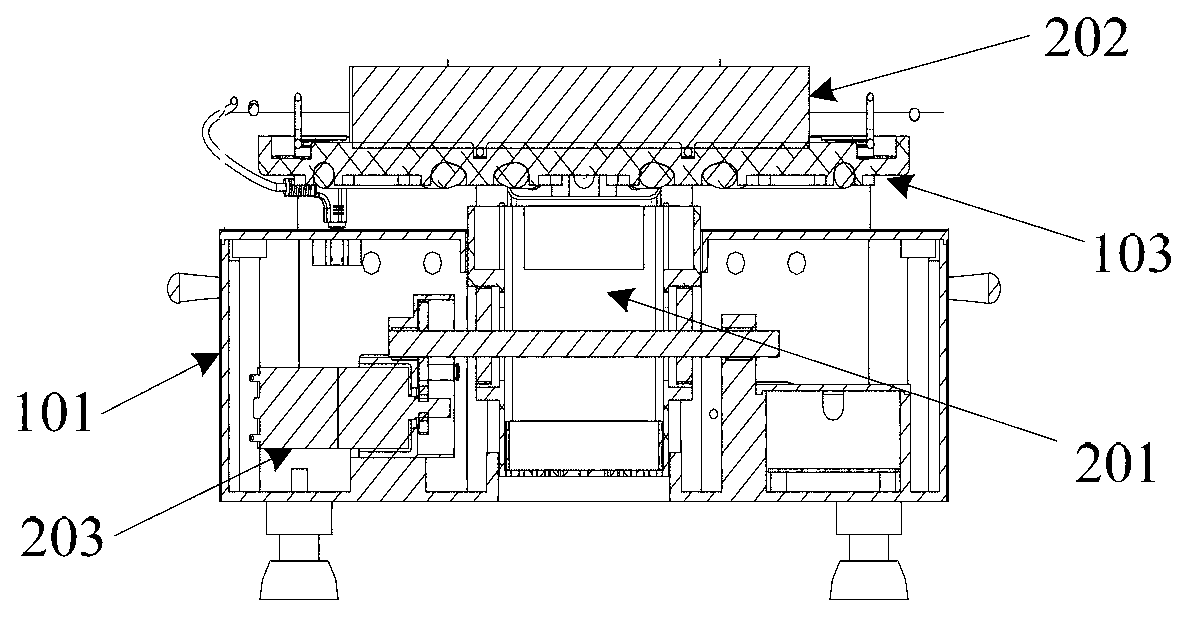

[0057] Further, see figure 2 and image 3 as shown, figure 2 It is the bottom view of the frying machine, image 3 for along figure 2 A cross-sectional view in the direction of A-A, the frying machine provided by the embodiment of the present invention may also include:

[0058] The up and down movement mechanism 201 is connected between the first heating plate 103 and the controller, and is used to drive the first heating plate 103 to move up and down under the control of the controller;

[0059] The controller is also used to control the movement of the up and down moving mechanism 201 according to the current temperature of the first heating plate 103 and the grilled food 202 .

[0060] The drive motor 203 in the fryer provided by the embodiment of the present invention is installed inside the first housing 101. The drive motor 203 can be vertical or horizontal, and the installation method is determined according to the specific shape of the fryer.

[0061] It shoul...

Embodiment 3

[0069] Further, the embodiment of the present invention also provides a grilling machine, see Figure 4 as shown, Figure 4 for along figure 2 Another cross-sectional view of the A-A direction, the frying machine also includes:

[0070] A second housing 401 movably connected to the first housing 101, and a second heating plate 402 installed on the second housing 401;

[0071] The second heating plate 402 is located above the first heating plate 103, and the baking pan 102 is interposed between the first heating plate 103 and the second heating plate 402;

[0072] The up and down moving mechanism 201 is also used to drive the second heating plate 402 to move under the control of the controller.

[0073] It should be noted that, in the embodiment of the present invention, the first heating plate 103 and the second heating plate 402 can be provided with heat by the same heating wire power supply, and the temperature of the first heating plate 103 and the second heating plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com