On-line glue heating device

A heating device and gluing technology, applied in non-electric variable control, instrument, temperature control and other directions, can solve problems such as improvement, and achieve the effect of meeting process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described below in combination with specific embodiments and with reference to the accompanying drawings.

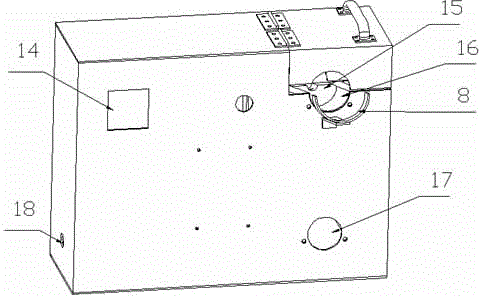

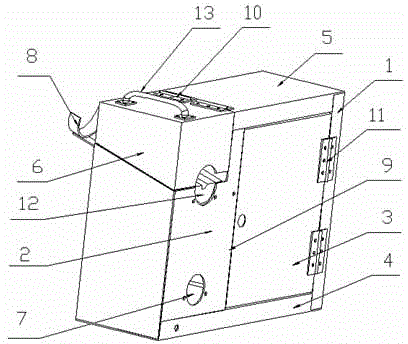

[0031] a kind of like Figure 1~2 The online gluing heating device shown is a cabinet structure, one side of the box body 1 is a heating cabinet 2 including heating components, and the other side of the box body 1 is an electrical cabinet including electrical components, between the heating cabinet 2 and In the middle of the electrical cabinet, there is a heat insulation board 9 perpendicular to the bottom plate 4 of the box body 1. The heat insulation board 9 is used to effectively isolate the heating components and electrical components, so as to ensure that the heat of the heating components will not cause thermal damage to the circuits and hardware of the electrical components. .

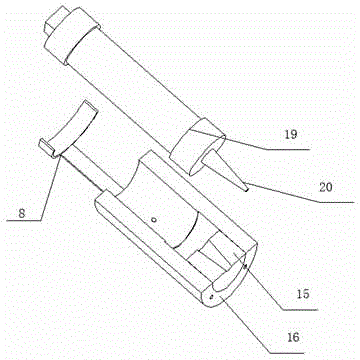

[0032] The heating components include a glue gun storage rack 8, a glue gun heating chamber 12 provided with a first resistance type heating tube and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com