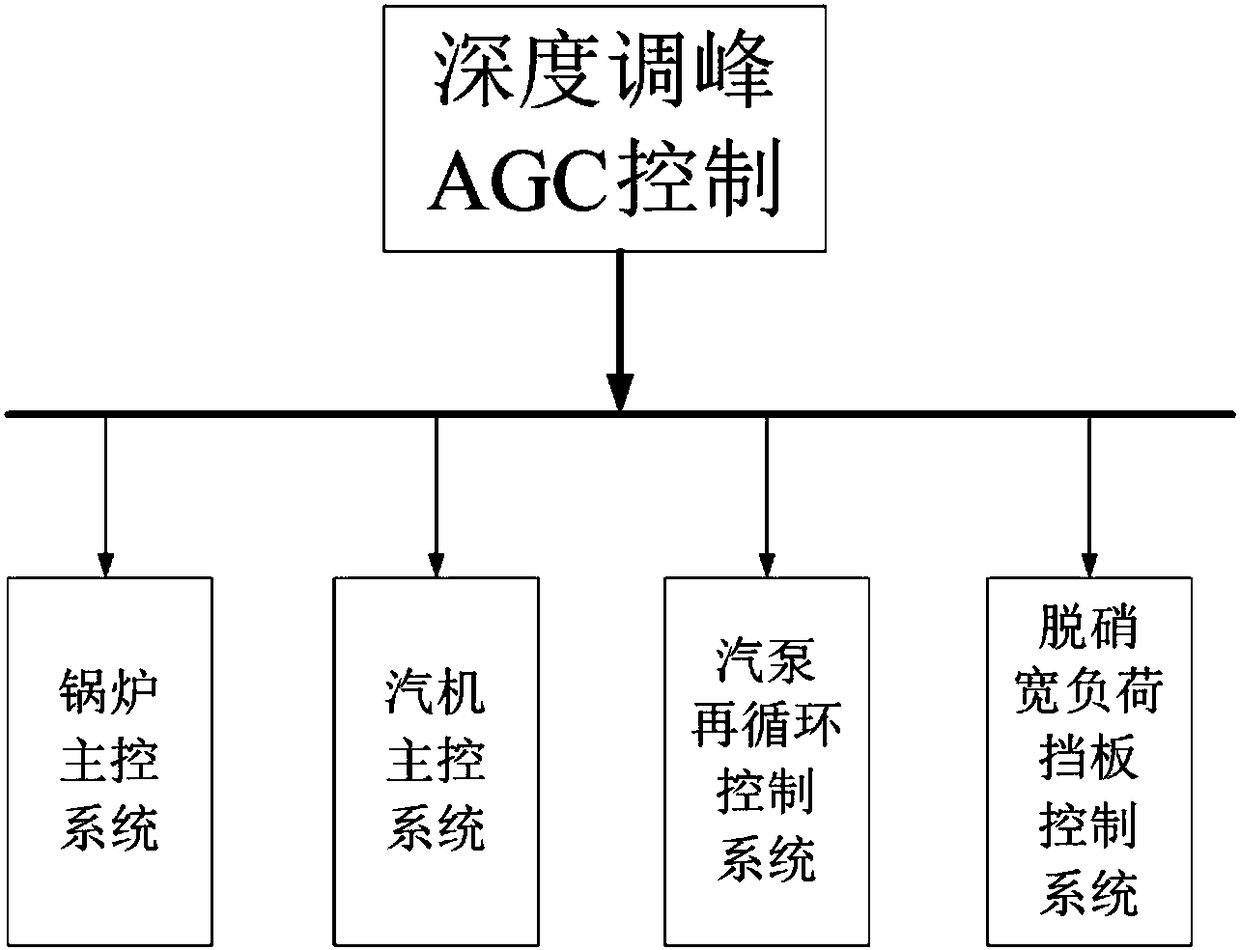

AGC (automatic gain control) control method for 660MW supercritical unit under deep peak-load regulation

A technology of supercritical unit and control method, which is applied in the directions of adaptive control, general control system, control/regulation system, etc., can solve the problems of unit shutdown, insignificant adjustment effect, and adjustment of flue gas temperature, so as to improve the safety and reliability of operation. , reduce pollutant over-emission, improve the effect of adjustment depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

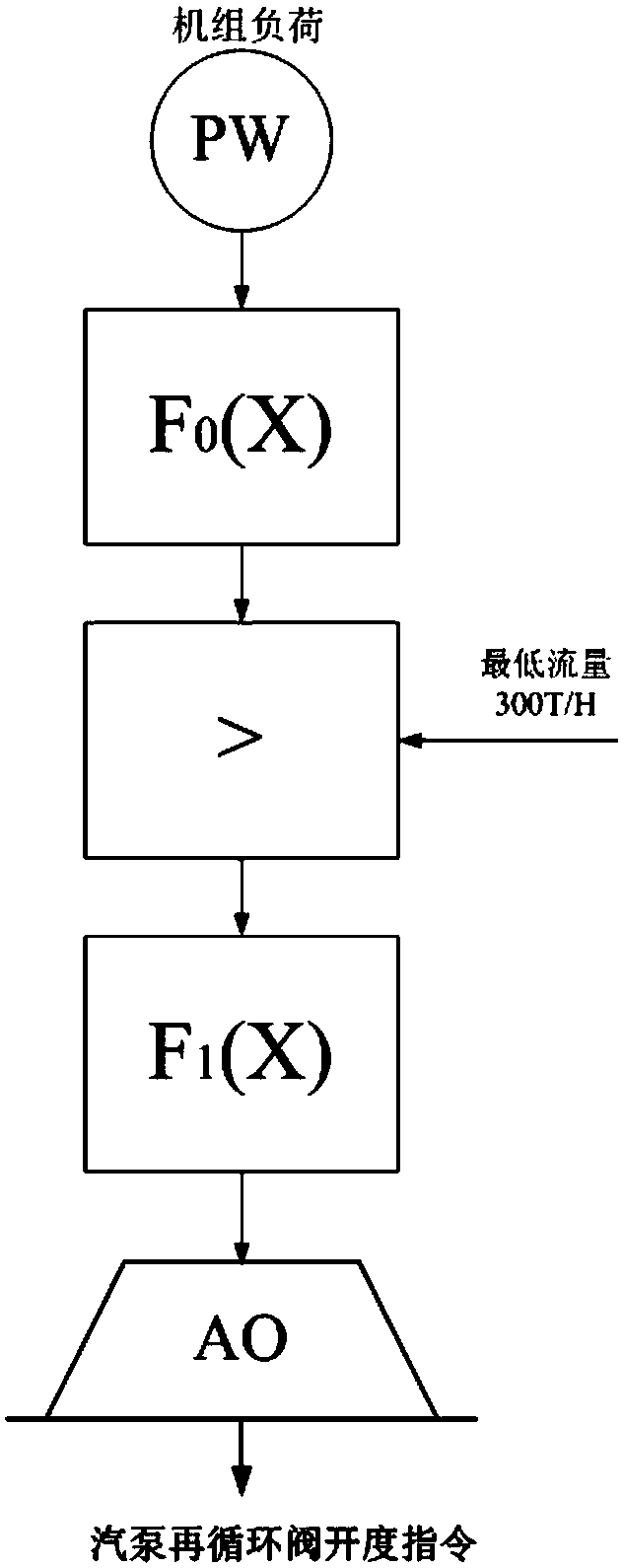

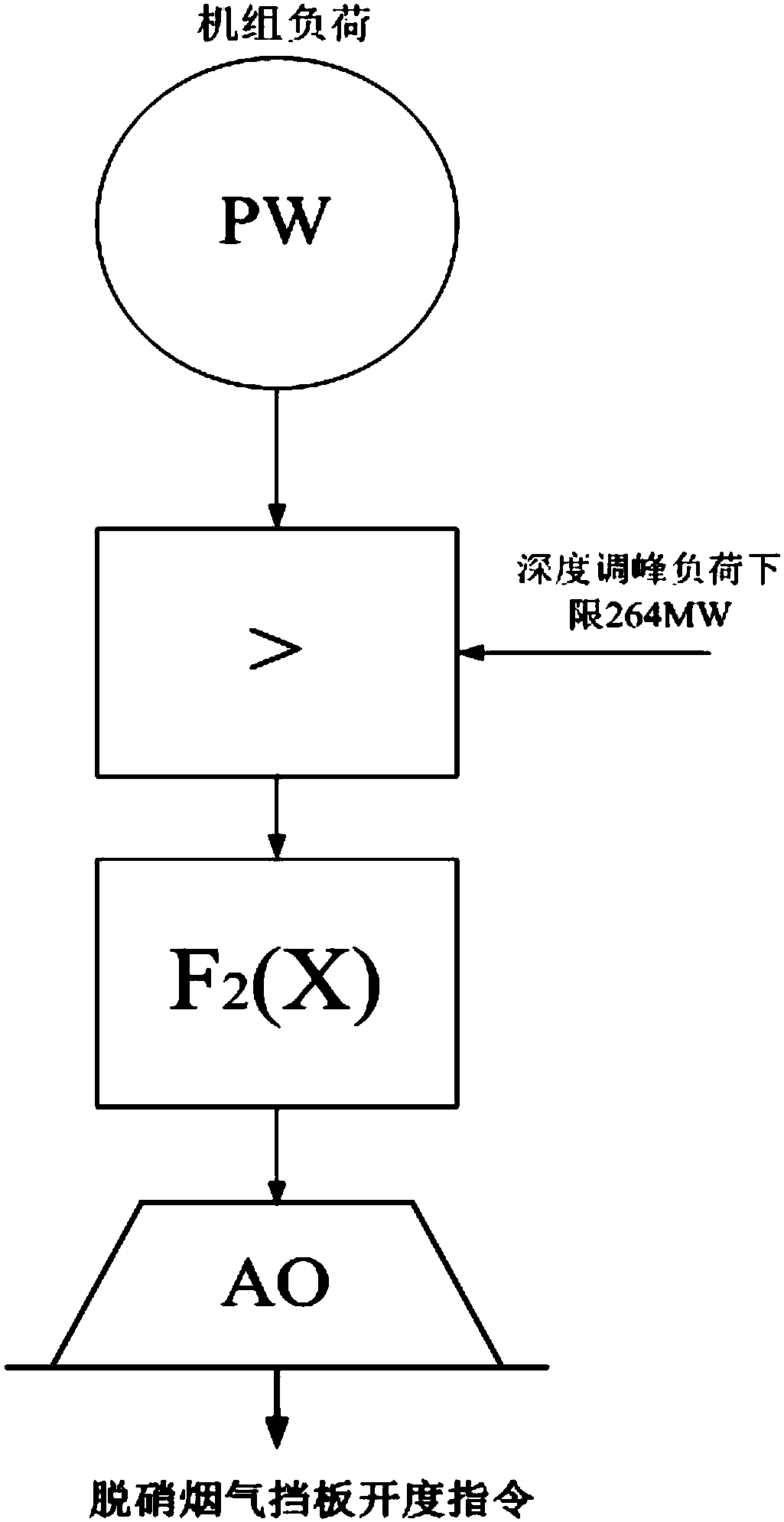

Embodiment 1

[0045] The original unit is designed to be put into AGC control mode above 330MW. Under this mode, two steam-driven feed water pumps (hereinafter referred to as "steam pumps") operate in parallel to supply boiler water supply. The flue gas baffle is in the manual full-open operation state, and the AGC lifting rate of the unit is 6.6MW / min. Generally, at least 4 sets of pulverizing systems are used for operation, and the adjustment of important auxiliary machines such as coal feeders, blowers, primary fans, and induced draft fans are all put into operation. automatic way. When the load is lower than 330MW, the operator switches the AGC mode to manual operation mode, artificially opens the steam pump recirculation regulating valve to control the feed water flow, and at the same time manually closes the opening of the denitrification wide-load flue gas baffle to increase the flue gas temperature Maintain the operation of the denitrification system. Obviously, when the load drops...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com