Energy-saving constant temperature automatic control method and device for movable grate boiler

An automatic control device and movable grate technology, which is applied in the boiler field, can solve the problems of large heating temperature error, large pollutant discharge, high fuel consumption, etc., and achieve the effects of reducing fuel waste, stabilizing the furnace temperature, and improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

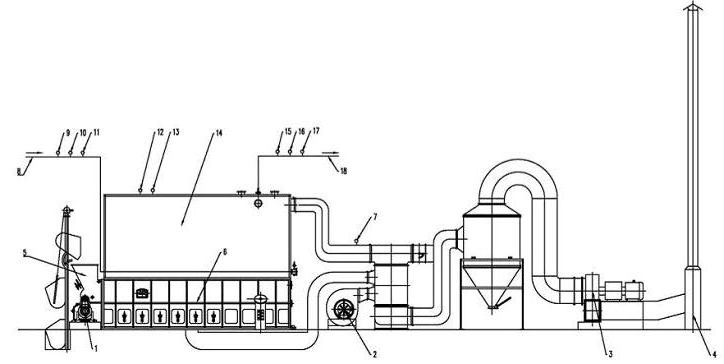

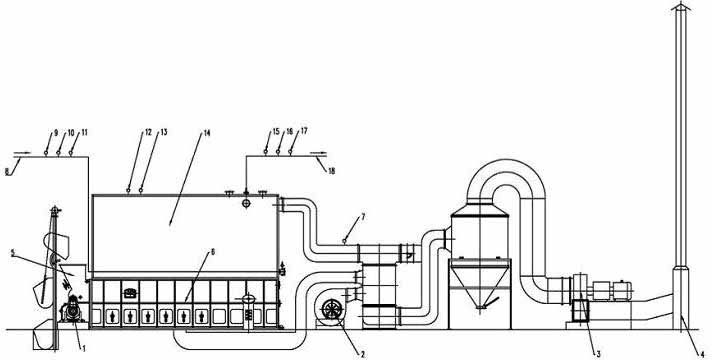

[0020] figure 1 As shown, the heat carrier input pipeline 8 of the present invention is equipped with a heat carrier input temperature transmitter 9, a heat carrier input pressure transmitter 10, a heat carrier input flow rate transmitter 11, a heat carrier input temperature transmitter 9, a heat carrier The input pressure transmitter 10, the heat carrier input flow transmitter 11 are connected with the control system operation unit; the heat carrier output temperature transmitter 15, the heat carrier output pressure transmitter 16, and the heat carrier output pipeline 18 are installed The output flow transmitter 17, the heat carrier output temperature transmitter 15, the heat carrier output pressure transmitter 16, and the heat carrier output flow transmitter 17 are connected with the operation unit of the control system; the furnace temperature transmitter is installed on the industrial boiler 14 Device 12, furnace differential pressure transmitter 13, furnace temperature tr...

Embodiment 2

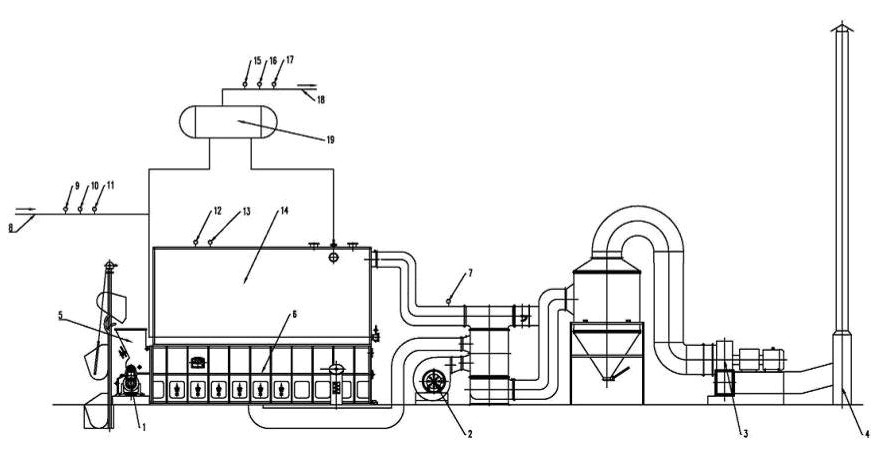

[0027] As shown in Figure 2, the heat carrier output temperature transmitter 15, heat carrier output pressure transmitter 16, and heat carrier output flow transmitter 17 of the present invention are installed on the heat carrier output pipeline 18 connected to the water vapor drum 19, and other The structure is exactly the same as in Example 1.

[0028]The working principle of the invention is: the heat carrier of the industrial boiler circulates continuously between the heating part and the heat-using equipment through the pipeline, so as to meet the heat demand of industrial production. The heat required by the heating equipment is constantly changing, but the temperature of the heat carrier input to the heating equipment is required to be relatively stable. The dynamic demand of fuel is calculated according to the dynamic temperature parameters of the heat carrier output by the industrial boiler, and the real-time adjustment is made by controlling the speed of the grate moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com