Environment-friendly heat conducting medium-free specimen stainer

A heat-conducting medium and environmentally friendly technology, applied in the field of dyeing, can solve the problems of low heating rate of dyeing cups, poor heating lag time of dyeing cups, and cooling rate of dyeing cup sleeves affecting high-temperature dyeing effects, etc., so as to improve the use range and high heating efficiency , Reduce the effect of sealing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

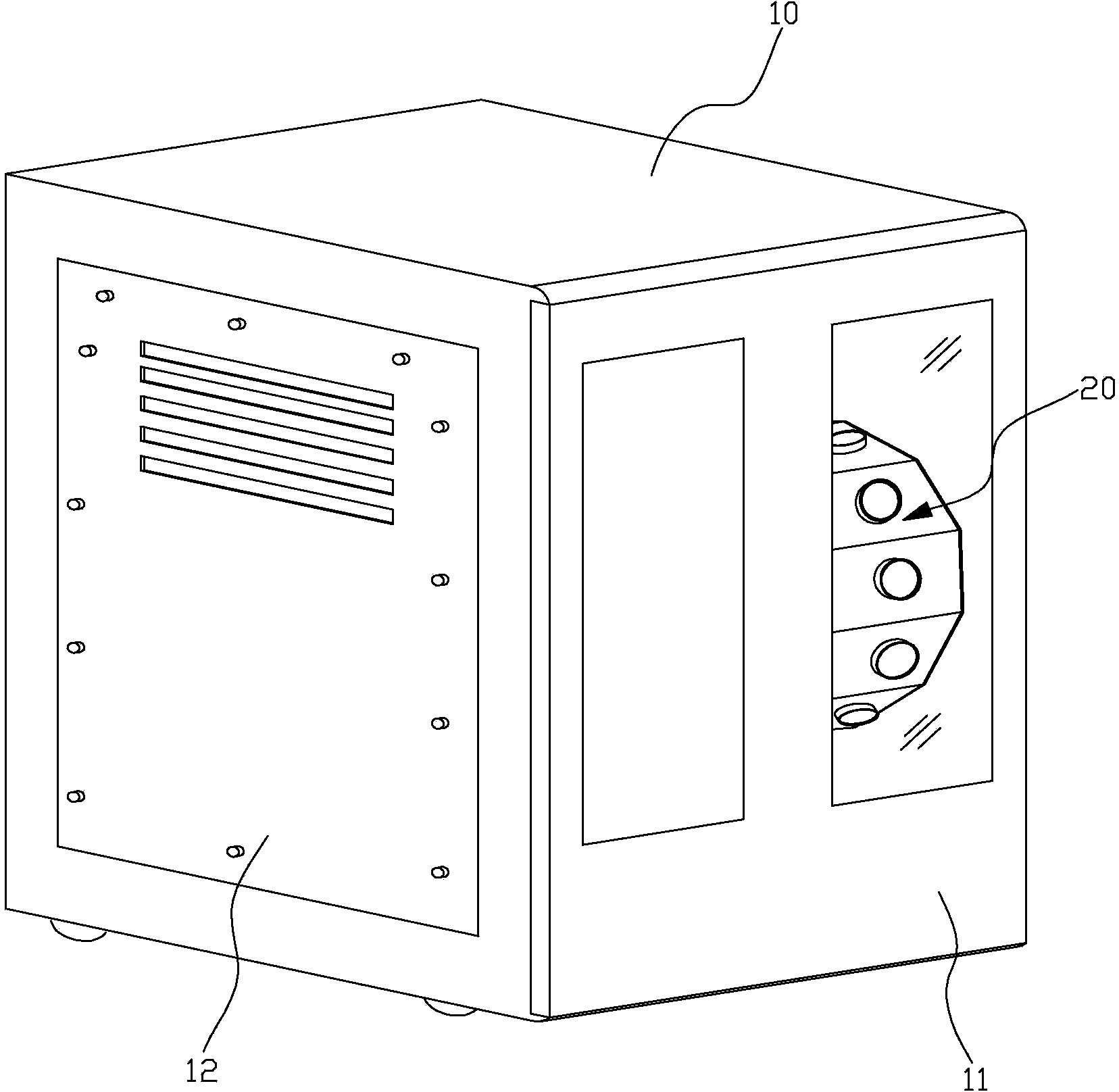

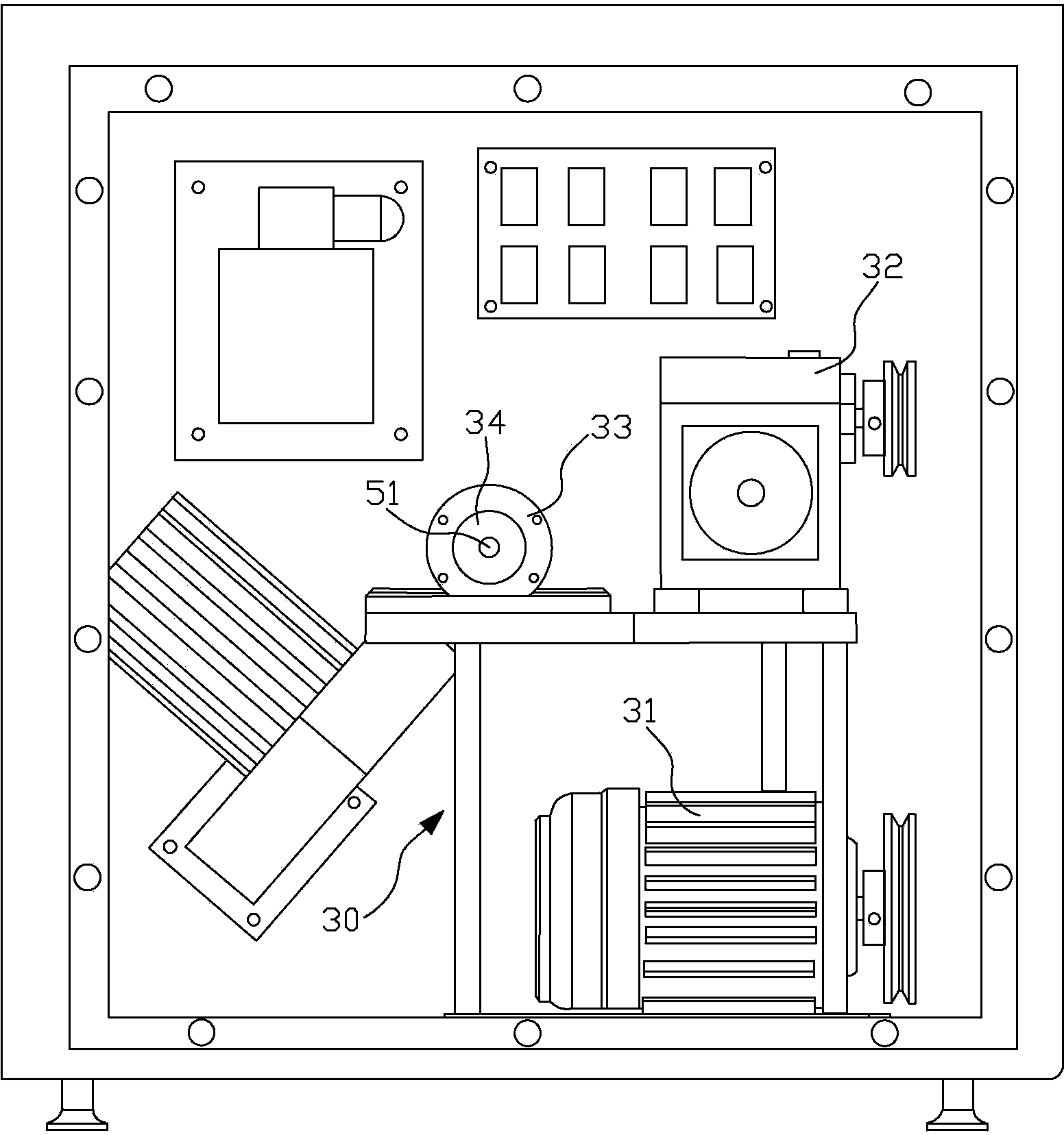

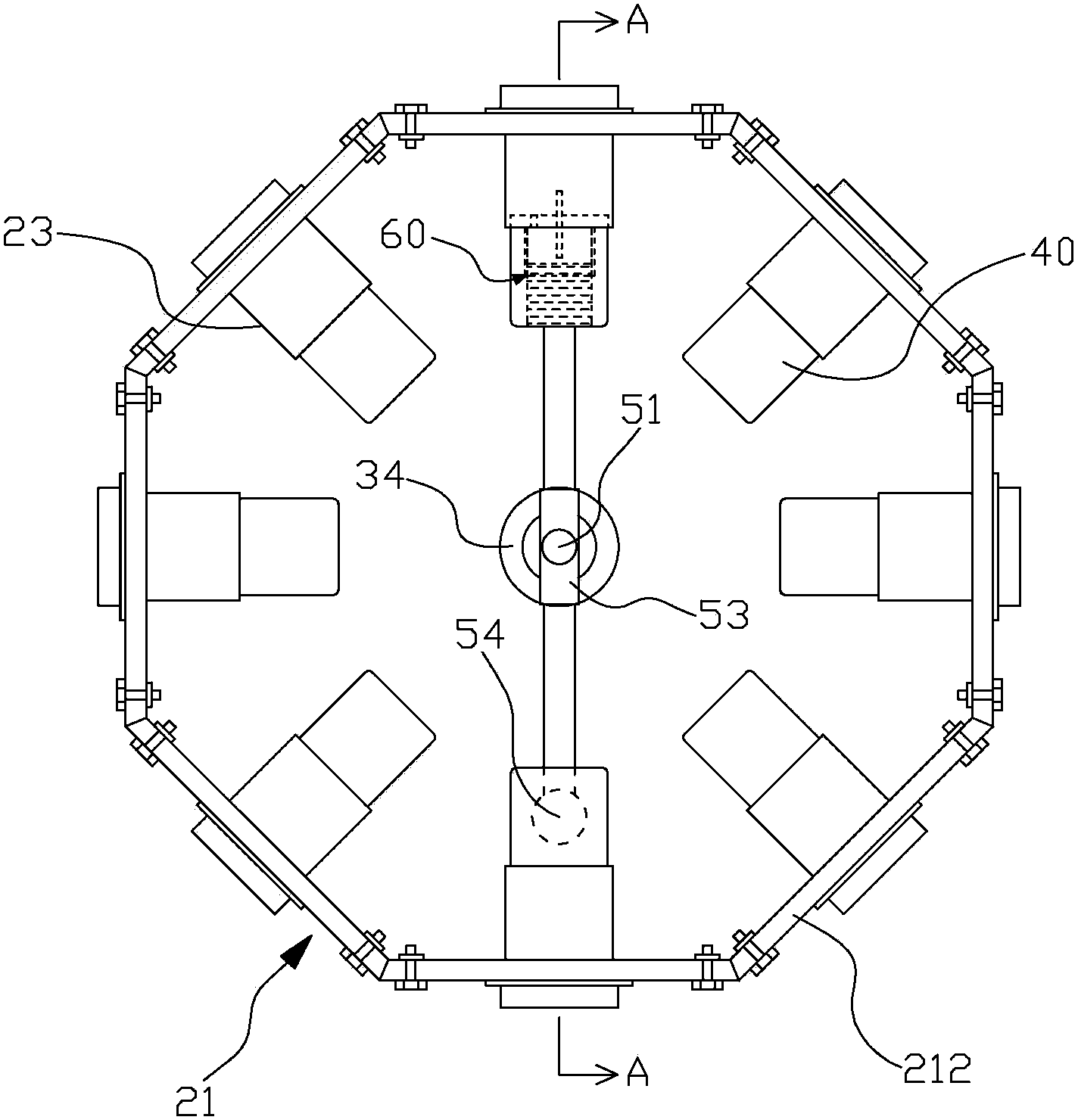

[0030] refer to figure 1 , figure 2 , image 3 and Figure 4 , an environment-friendly non-heat-conducting medium sample dyeing instrument, including a chassis 10, a rotating frame 20, a rotating frame driving mechanism 30, a dyeing cup 40, a heating device 50 and a temperature detection device 60. The cabinet 10 is divided into a heating chamber 11 and a driving chamber 12 , the rotating frame 20 is disposed in the heating chamber 11 , and the rotating frame driving mechanism 30 is disposed in the driving chamber 12 .

[0031] Rotating frame 20 comprises rotating frame body 21, mounting hole 22, first insulation cover 23 and positioning cover 24, and rotating frame body 21 is a hollow structure, comprises two regular polygonal end plates 211 of symmetrical arrangement and detachable connection between two The cover plate 212 between the end plates 211 is surrounded by the end plate 211 and the cover plate 212 to form a prism structure. Each cover plate 212 is provided wi...

Embodiment 2

[0040] An environment-friendly non-heat-conducting medium small sample dyeing instrument, including a chassis, a rotating frame, a rotating frame driving mechanism, multiple dyeing cups, a heating device and a temperature detection device, wherein the temperature detection device 60 uses any dyeing cup 40 as a temperature measuring cup to measure the temperature. There is a temperature measuring rod in the cup to detect the temperature of the dyeing cups. Since the temperature of each dyeing cup is the same, the temperature measured by using the dyeing cup as a temperature measuring cup has high precision and simple structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com