An experimental device for on-line detection and control of welding temperature of high-frequency straight seam welded pipes

A technology of straight seam welded pipe and welding temperature, applied in welding equipment, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of affecting the quality of the weld, difficult to guarantee the stability, and over-burning of the weld, and achieve the effect of ensuring the quality of the welded pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

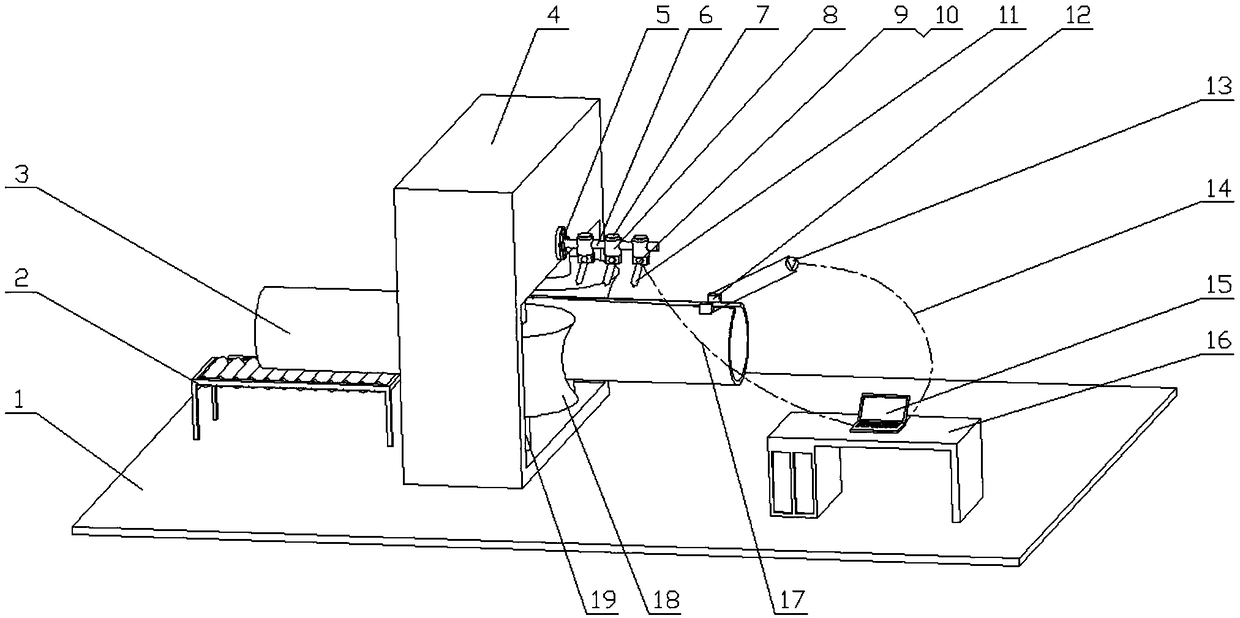

[0011] exist figure 1 In the three-dimensional schematic diagram of the ERW steel pipe welding temperature on-line detection and control experimental device shown, the two ends of the high-frequency generator and its output device 13 are connected to the two electrode contacts 12 through the circuit, and the two electrode contacts are connected by welding The seam is pressed symmetrically on the tube blank 3 as the center. The welding seam of the tube blank is located in the center above it, and the two sides of the welding seam are located in a pair of extrusion rollers 18, and the upper and lower ends of the vertical roller shaft 19 of the pair of extrusion rollers are installed on the machine fixed on the ground 1 respectively. In the frame 4, the tube blank is placed on the cylinder conveyor 2 close to the frame, and the side facing the high-frequency generator on the frame is vertically connected with one end of the support rod 6 through a screw 5, and its axis is paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com