Improved high-power thyristor

A thyristor and high-power technology, applied in the field of high-power thyristors, can solve problems such as easy deviation, unpredictability, and junction temperature drift, and achieve the effects of small measurement error, reduced temperature deviation, and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

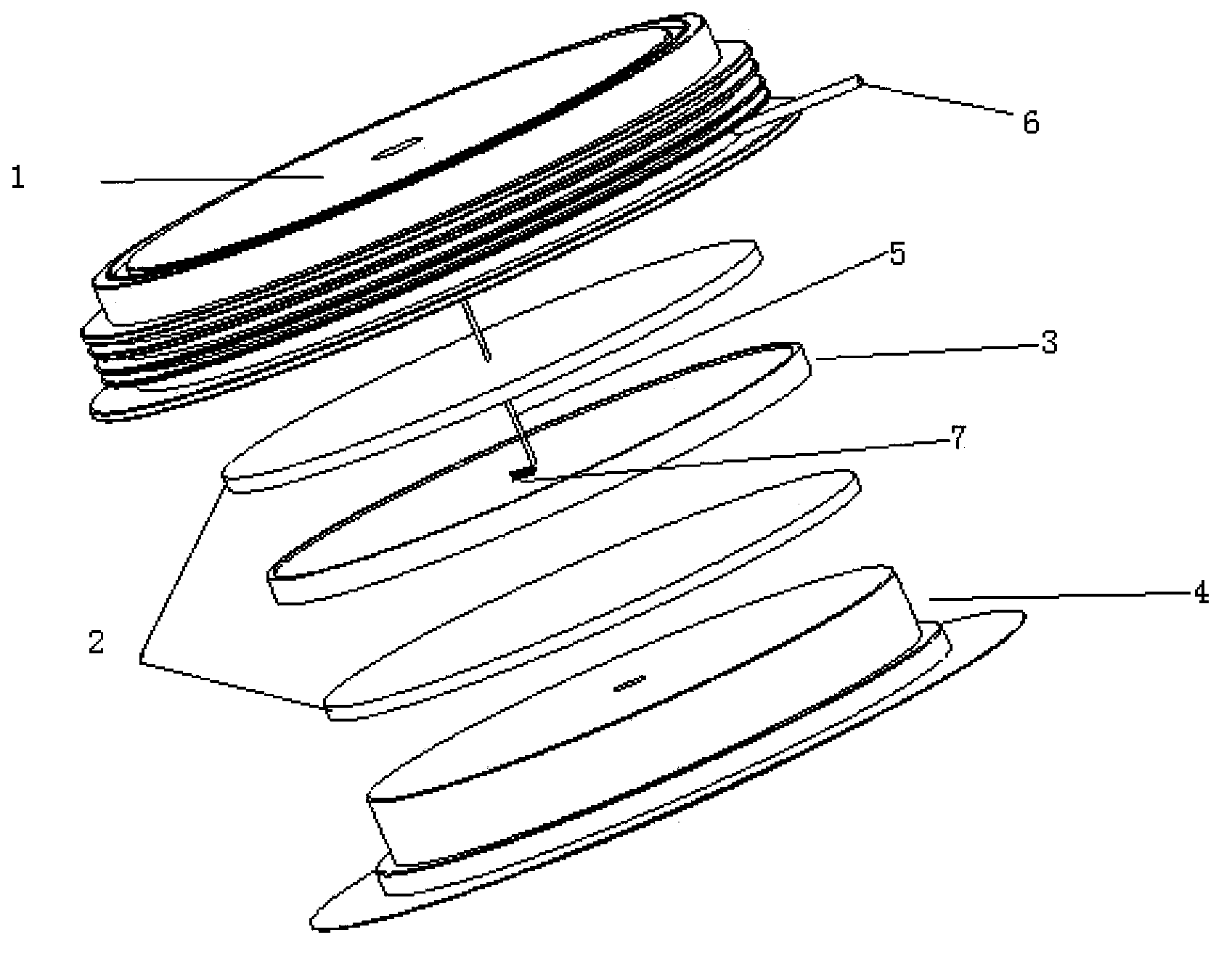

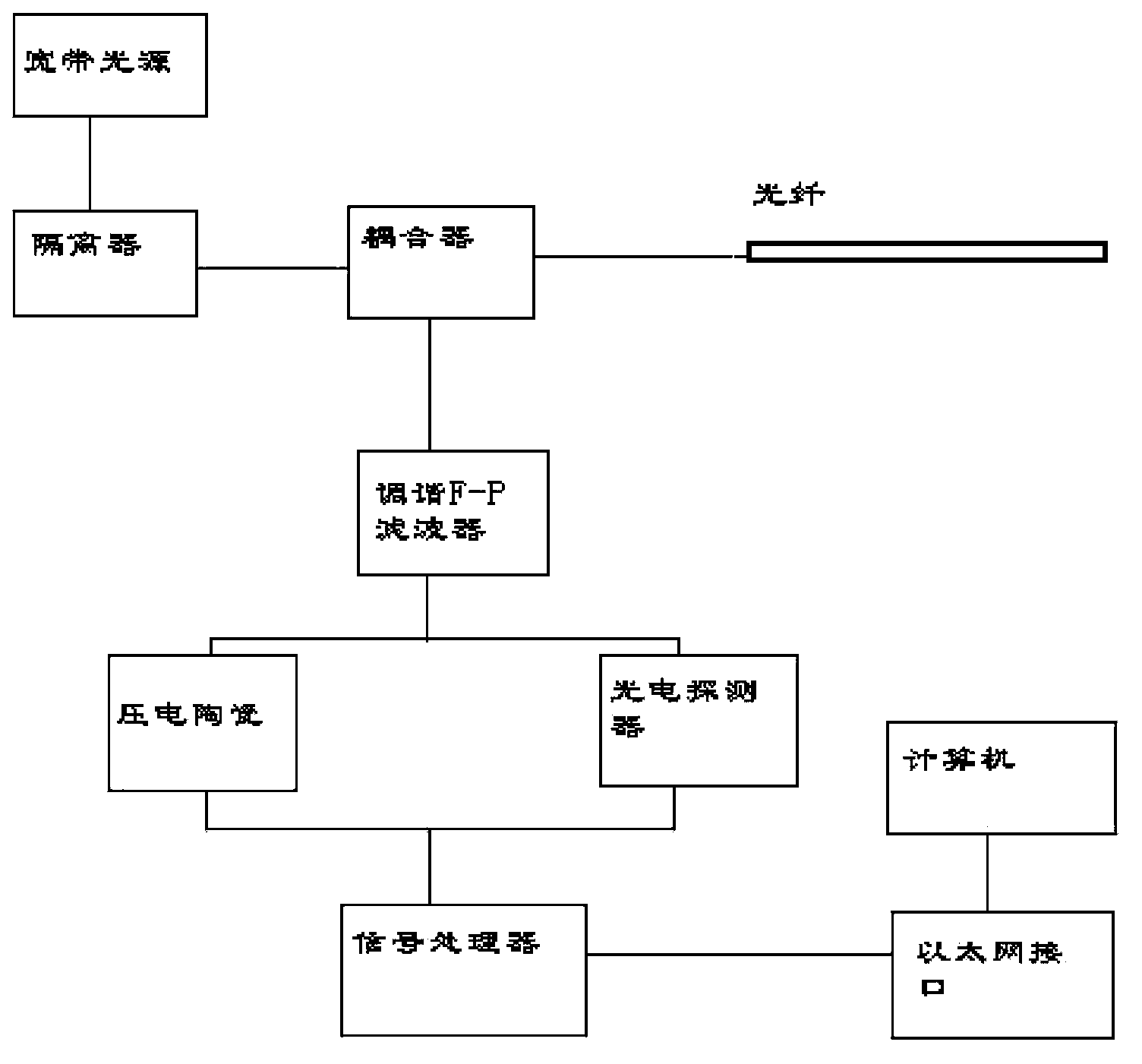

[0031] Such as Figure 1-2 As shown, in the invention of this example, it is a 6-inch thyristor, which includes a ceramic ring shell, a tube base 1, two layers of protective layers 2 wrapped outside the chip 3, and a tube cover 4; the temperature sensor includes a grating 7 and an optical fiber, so The optical fiber includes a bare optical fiber 5 and an outer armored optical fiber 6, and the bare optical fiber 5 is arranged inside the thyristor. A hole is radially opened on the edge of the tube base 1 , and the bare optical fiber 5 passes through the radial hole to the axial hole on the inner surface of the tube base, and is connected to the chip 3 through the radial hole of the protective layer 2 below the tube base 1 . The chip 3 includes an anode-side molybdenum sheet, a silicon sheet and a cathode-side molybdenum sheet that are buckled axially into the ceramic ring shell sequentially. The silicon wafer includes a phosphorus-expanded region N+, a short base region P1, a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com