SiC single crystal production method and SiC single crystal production device

A manufacturing method and a manufacturing device technology, which are applied in the field of manufacturing methods and SiC single crystal manufacturing devices, can solve problems such as hindering the growth of SiC single crystals, and achieve the effect of reducing temperature deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0045][Overall structure of SiC single crystal manufacturing apparatus 100]

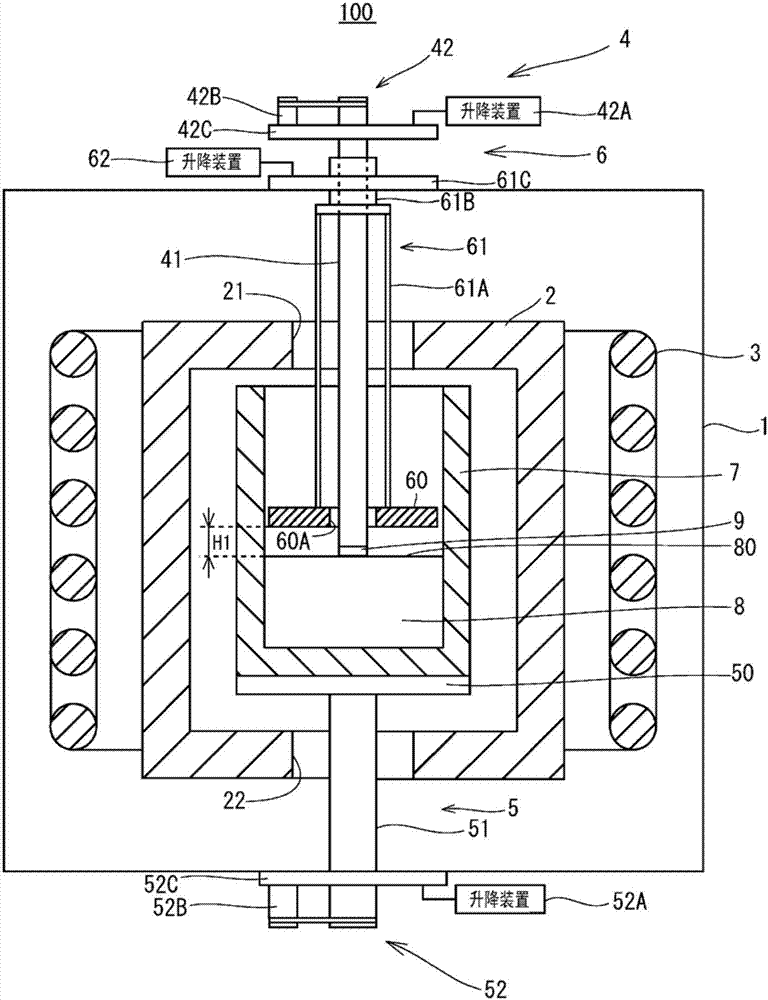

[0046] figure 1 It is an overall configuration diagram of the SiC single crystal manufacturing apparatus 100 of the first embodiment. like figure 1 As shown, the manufacturing device 100 includes a box body 1 , a heat insulating member 2 , a high-frequency heating coil 3 , a seed shaft driving mechanism 4 , a crucible driving mechanism 5 and a middle cover driving mechanism 6 .

[0047] The box body 1 is a frame body capable of accommodating the heat insulating member 2 , the high-frequency heating coil 3 , and the seed shaft 41 in the seed shaft driving mechanism 4 . The box 1 is also capable of housing a crucible 7 . When producing a SiC single crystal, the box 1 is water-cooled.

[0048] The crucible 7 is accommodated in the frame-shaped heat insulating member 2 . The crucible 7 is a frame with an open upper end. The crucible 7 can accommodate the Si—C solution 8 . The Si—C solution 8 is ...

no. 2 Embodiment approach

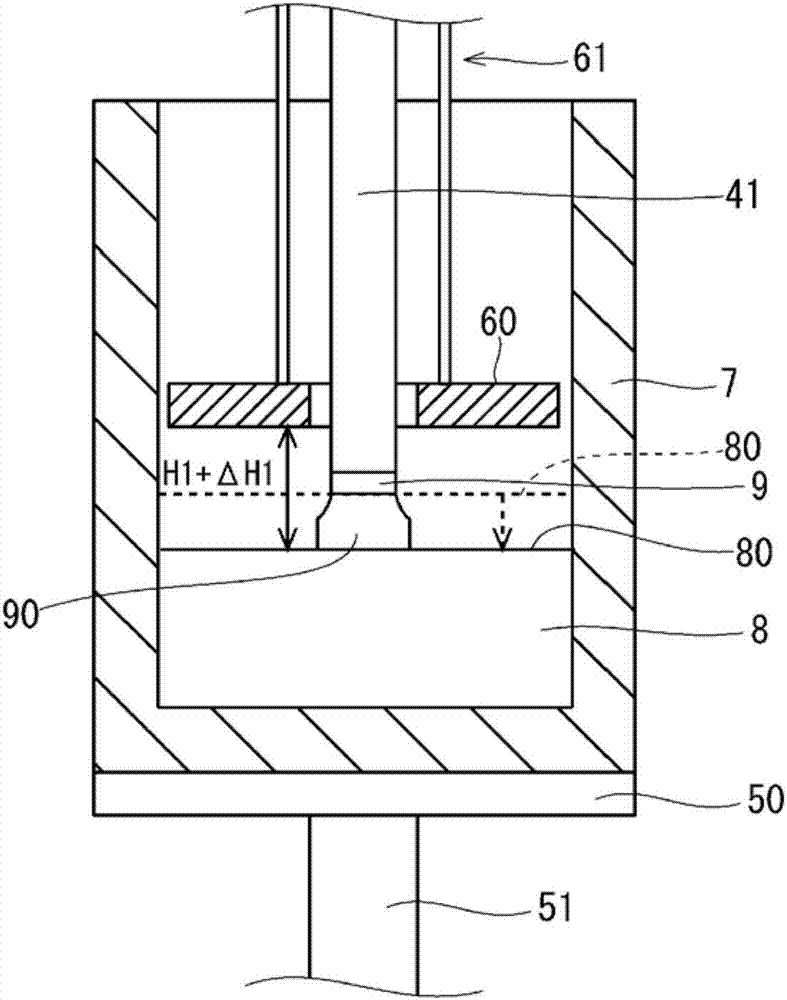

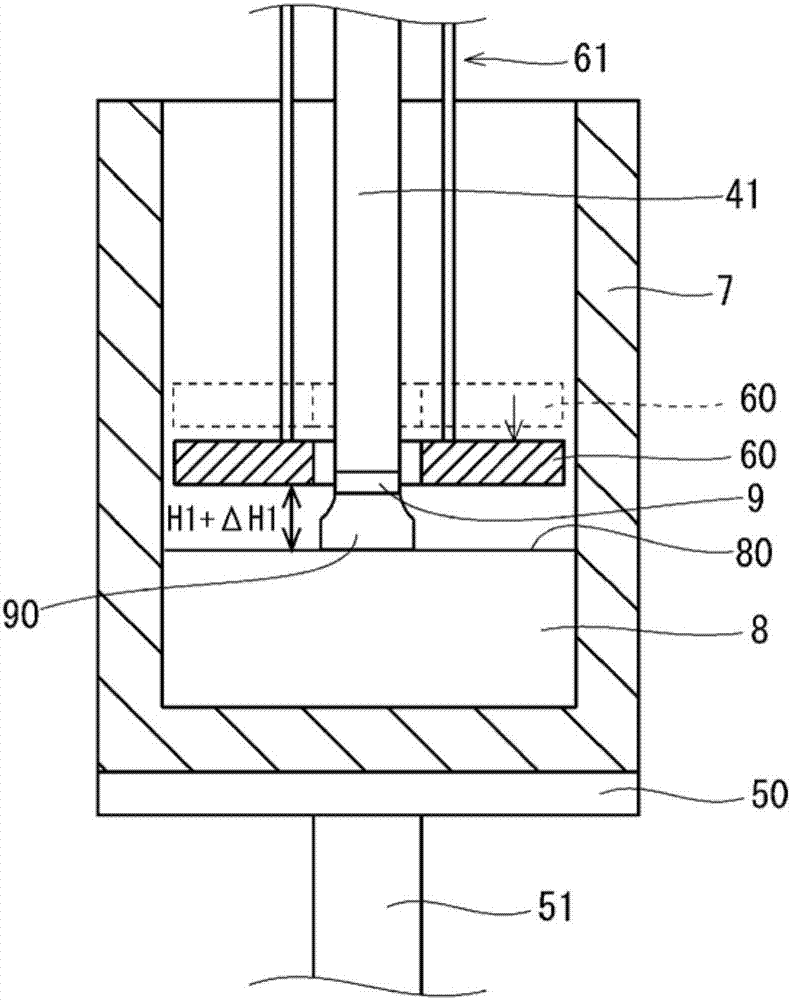

[0096] In the first embodiment, in order to suppress the temperature deviation between the vicinity of the Si—C solution 8 and the surrounding area, the fluctuation range ΔH1 of the distance between the middle cover 60 and the liquid surface 80 is adjusted within the reference value Ref1.

[0097] Moreover, when the liquid level 80 falls, the positional relationship (relative positional relationship in the height direction) between the liquid level 80 and the high frequency coil 3 changes. In this case, the heating conditions for heating the Si—C solution 8 by the high-frequency coil 3 are likely to change. Therefore, it is preferable to maintain the positional relationship between the liquid surface 80 and the high-frequency coil 3 when the crystal growth starts.

[0098] Figure 5 It is an overall configuration diagram of a SiC single crystal manufacturing apparatus 200 according to the second embodiment. refer to Figure 5 , compared with the manufacturing device 100 , t...

Embodiment

[0108] SiC single crystals were produced under the production conditions of Invention Example 1 to Invention Example 3, Comparative Example 1 and Comparative Example 2 shown in Table 1, and the quality of the obtained SiC single crystals was evaluated.

[0109] Table 1

[0110]

[0111] [Example 1 of the present invention]

[0112] For the raw material components of the Si—C solution, according to the atomic ratio, Si:Cr=0.6:0.4. The temperature (crystal growth temperature) of the portion near the seed crystal in the Si—C solution was 1900°C. The temperature gradient in the region near the seed crystal was 15°C / cm. The seed crystal used is a 4H polytype SiC single crystal, and its lower surface (crystal growth plane) is a (000-1) plane. The height of the meniscus at which crystal growth begins is 0.5 mm.

[0113] As a manufacturing device, used with figure 1 Manufacturing apparatus 100 with the same structure. In Example 1 of the present invention, the height posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com