Water-cooled wall of boiler with double collecting boxes at middle part

A water-cooled wall and double header technology, which is applied in the field of boiler water-cooled walls, can solve problems such as uneven temperature distribution, and achieve the effect of solving the large temperature deviation of the working medium and having a good application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The principle, specific structure and best implementation mode of the present invention will be further described below in conjunction with the accompanying drawings.

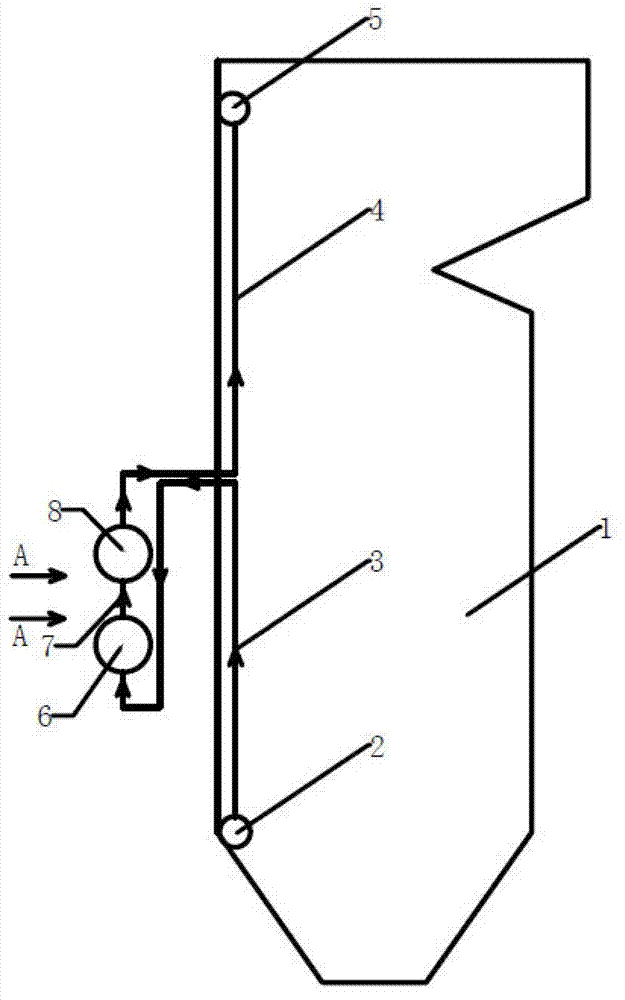

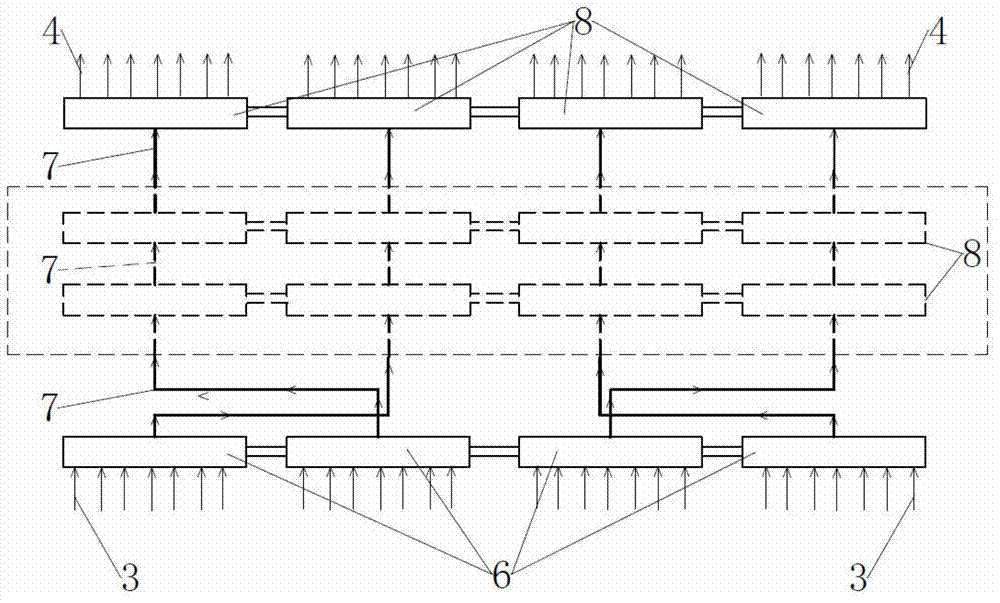

[0015] figure 1 It is a schematic diagram of a water wall with double headers in the middle of the boiler. The water wall mainly includes water wall inlet header 2, lower furnace water wall 3, mixing header 6, connecting main pipe 7, distribution header 8, upper furnace water wall 4 and water wall outlet header 5. The water-cooled wall 3 of the lower furnace is led out from the inlet header 2 of the water-cooled wall and connected with the mixing header 6 in the middle of the boiler. Since the heat load in the lower furnace along the width and depth of the furnace 1 is unevenly distributed, the water-cooled wall of the lower furnace 3. The working fluid at the outlet already has a temperature deviation. The working fluid with different temperatures from the lower furnace water wall 3 is mixed in the mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com