A manufacturing method of whole soybean milk and soybean curd

A manufacturing method and technology for soybean milk, which are applied in the directions of food preparation, rigid containers, containers, etc., can solve the problems of difficult operation, poor taste, and inability to guarantee quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Whole soybean milk I is manufactured according to the method of the present invention

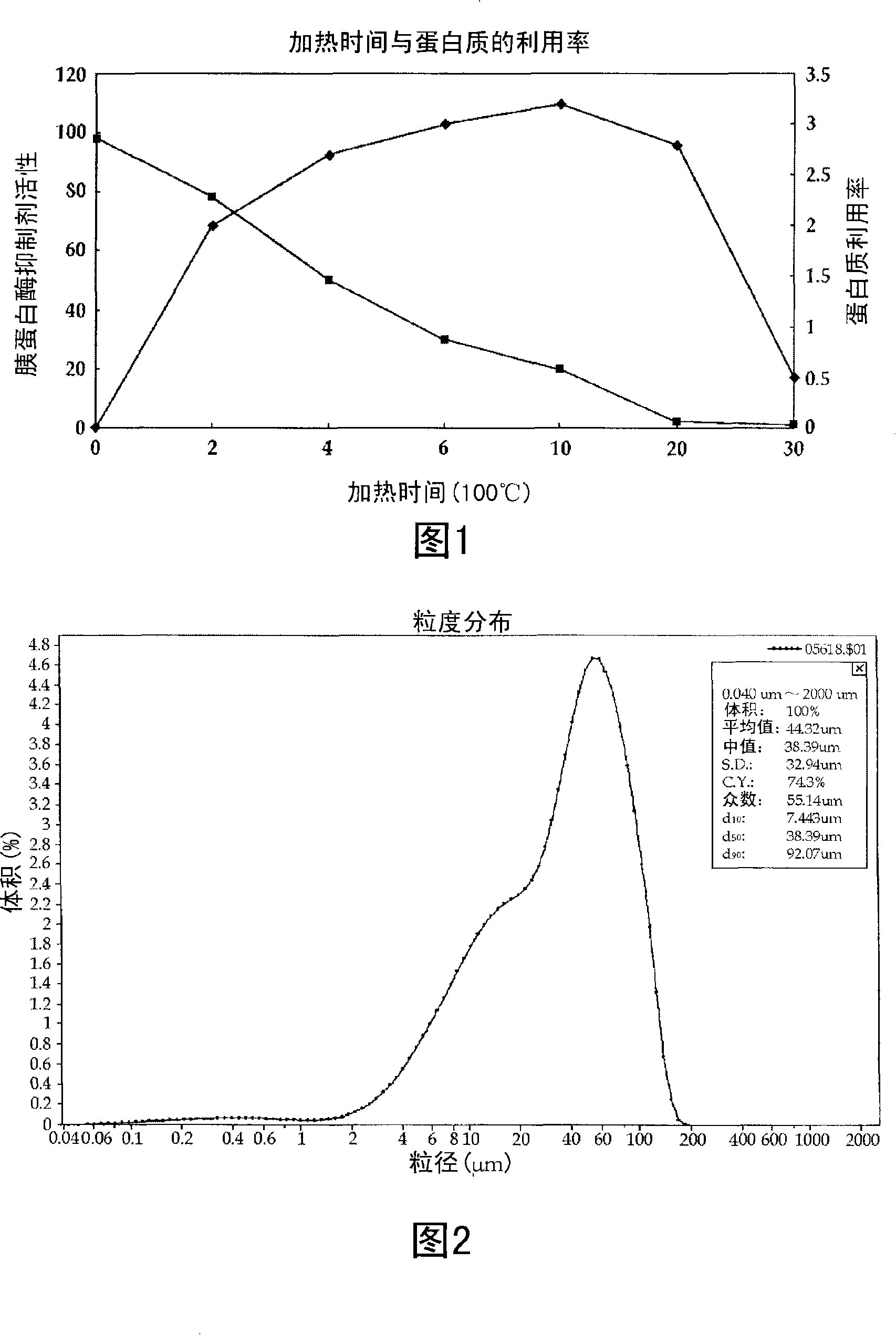

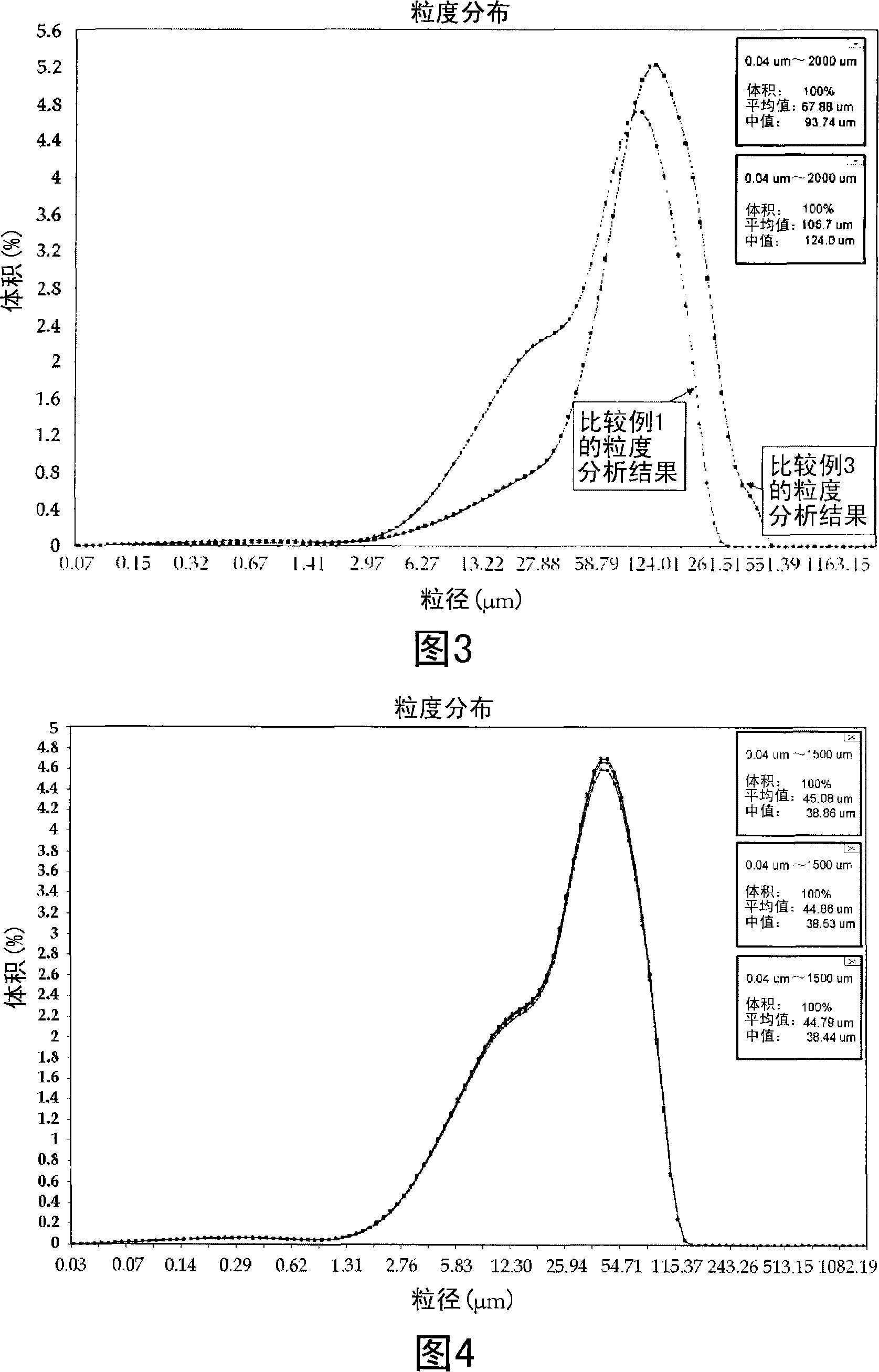

[0088] 100g of soybeans were removed with a peeler. 5 times (weight ratio) of water was added to the peeled soybeans, and water immersion was performed for 3 to 6 hours. The soybeans were taken out, and 4 to 5 times (weight ratio) of water was added to the hydrated soybeans, and coarsely pulverized with a grinder (manufactured by Continental Machinery). At this time, the particle size of the soybean coarsely ground material is about 100 to 3000 μm. The above coarsely ground soybeans were heated at 100° C. for 10 minutes, and cooled to 0 to 10° C. with a cooling machine. Then, the above-mentioned coarsely ground soybeans were finely pulverized using an ultrafine pulverizer (manufactured by Masuko). At this time, the upper grinding part (MKG-A) of the ultrafine pulverizer is fixed, and the lower grinding part (MKG-A) is moved up and down at an interval of 1 / 100mm by rotating the a...

Embodiment 2

[0090] According to the method of the present invention to make whole bean soymilk II

[0091] Except for adding 0.002 to 0.2% by weight of fatty acid antifoaming agent (manufactured by RikenVita Co., Ltd.) relative to the total amount of coarse soybean pulverization when pulverizing with an ultrafine pulverizer, a whole Soy milk.

Embodiment 3

[0093] According to the method of the present invention to make whole bean soymilk III

[0094]Whole bean soymilk was produced in the same manner as in Example 2 above, except that a measuring table ultrafine pulverizer was connected in series to the production line for ultrafine pulverization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com