Air-cooling radiator and manufacturing method thereof

A manufacturing method and radiator technology, applied in the direction of cooling/ventilation/heating transformation, can solve the problems of affecting the heat dissipation effect of the radiator and increasing the contact thermal resistance, so as to achieve the improvement of the heat dissipation effect, the improvement of the heat dissipation effect, and the centralized and balanced air volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In the following, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, so as to understand the technical ideas claimed in the present invention more clearly.

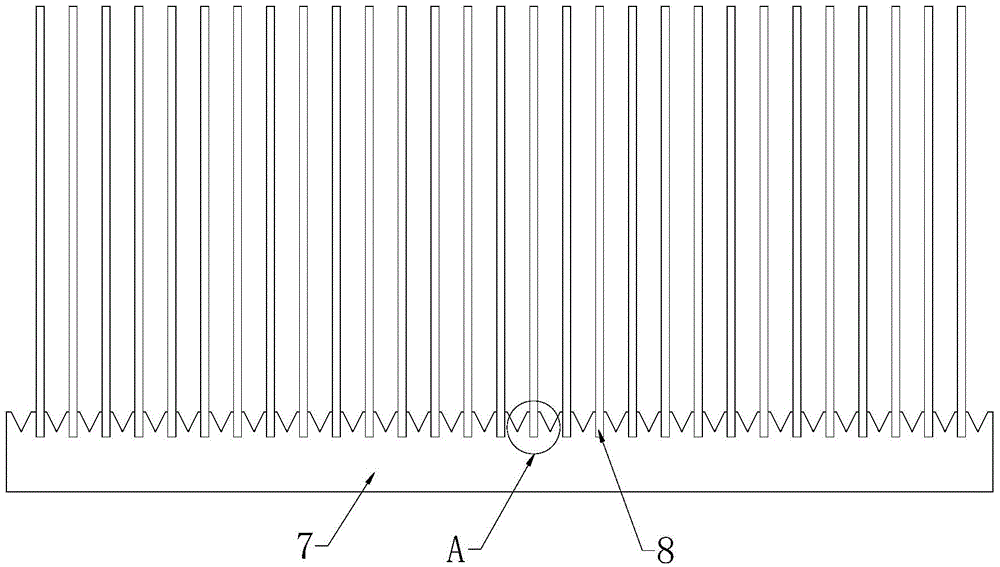

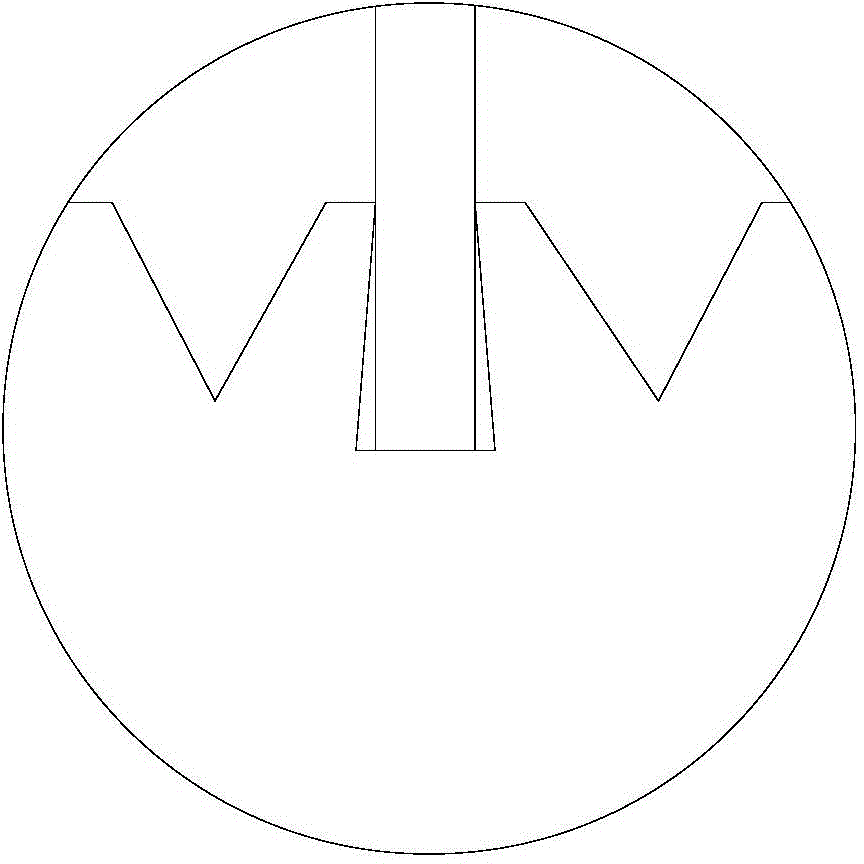

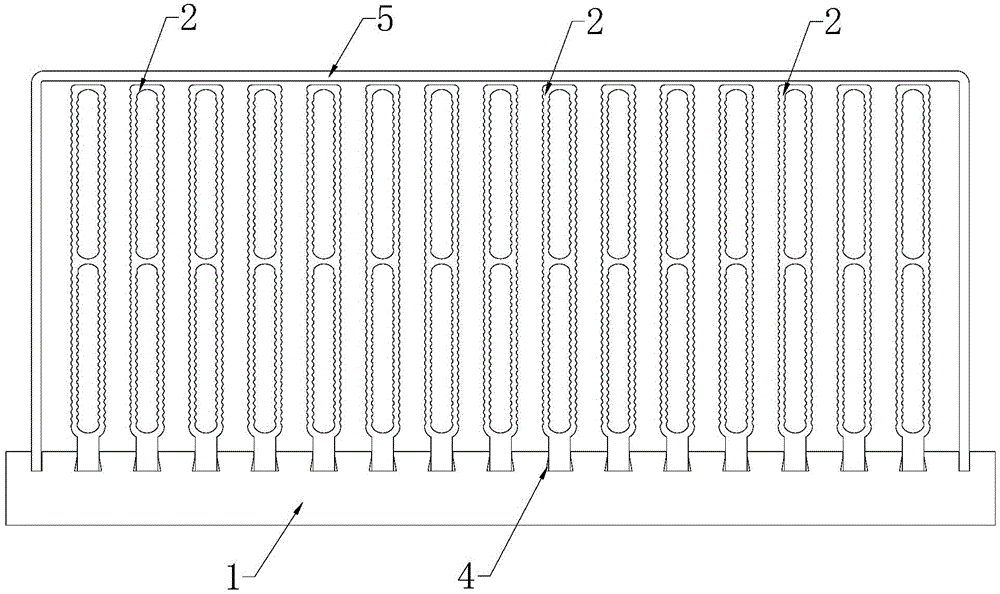

[0032] Such as image 3 , 4 , 5, it is an air-cooled radiator of the present invention, including a heat conduction substrate 1 and a heat sink 2; the heat conduction substrate 1 is provided with a slot 11, and the connection end of the heat dissipation fin 2 is fixed on the heat conduction The slots 11 of the substrate 1 and between the connecting end of the heat sink 2 and the slots 11 are filled with a heat conduction medium 4 ; the heat sink 2 is also formed with an air passage 21 .

[0033] During use, the heat conduction substrate 1 absorbs the heat of the heating element and conducts it to the heat sink 2, and the heat conduction medium 4 can reduce the thermal resistance between the heat conduction substrate 1 and the heat dissipation fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com