Teflon cold and heat exchanger

A cold heat exchanger, Teflon technology, applied in heat exchange equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problems of small flow, less unit heat exchange area, and smaller heat transfer coefficient , to achieve the effect of small outlet temperature deviation, energy saving and material saving, and high heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

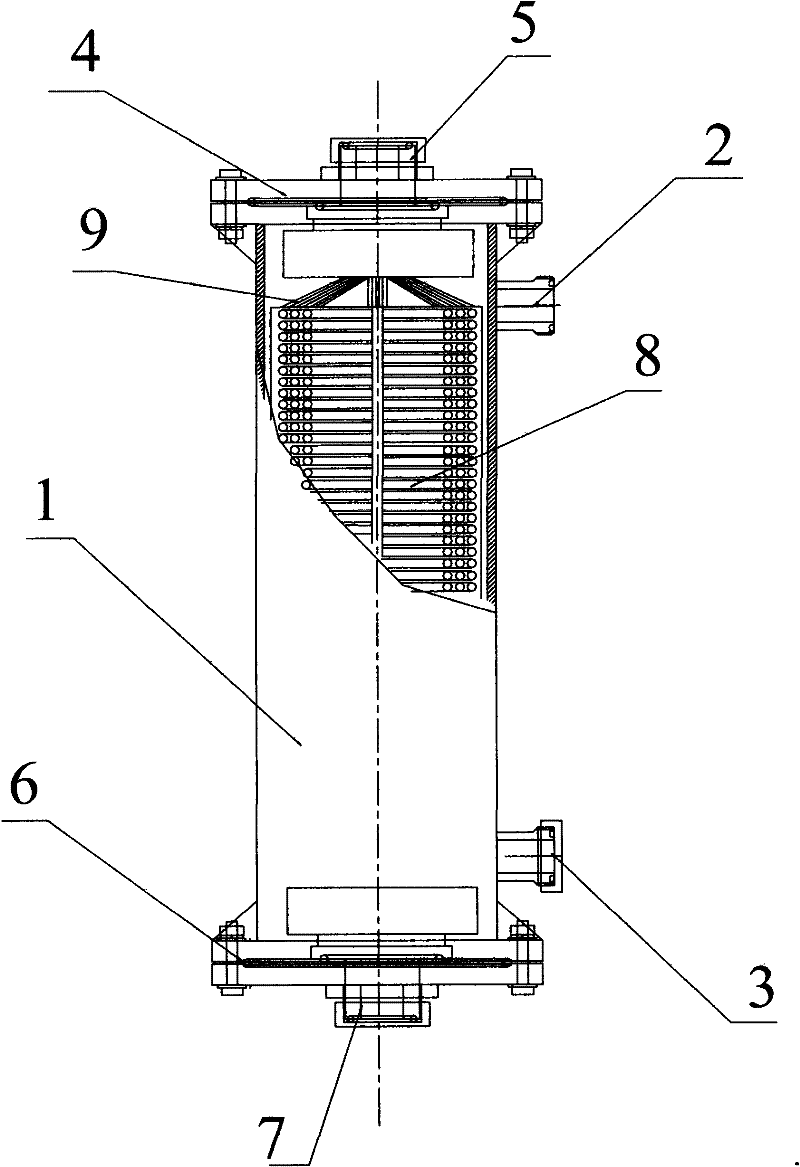

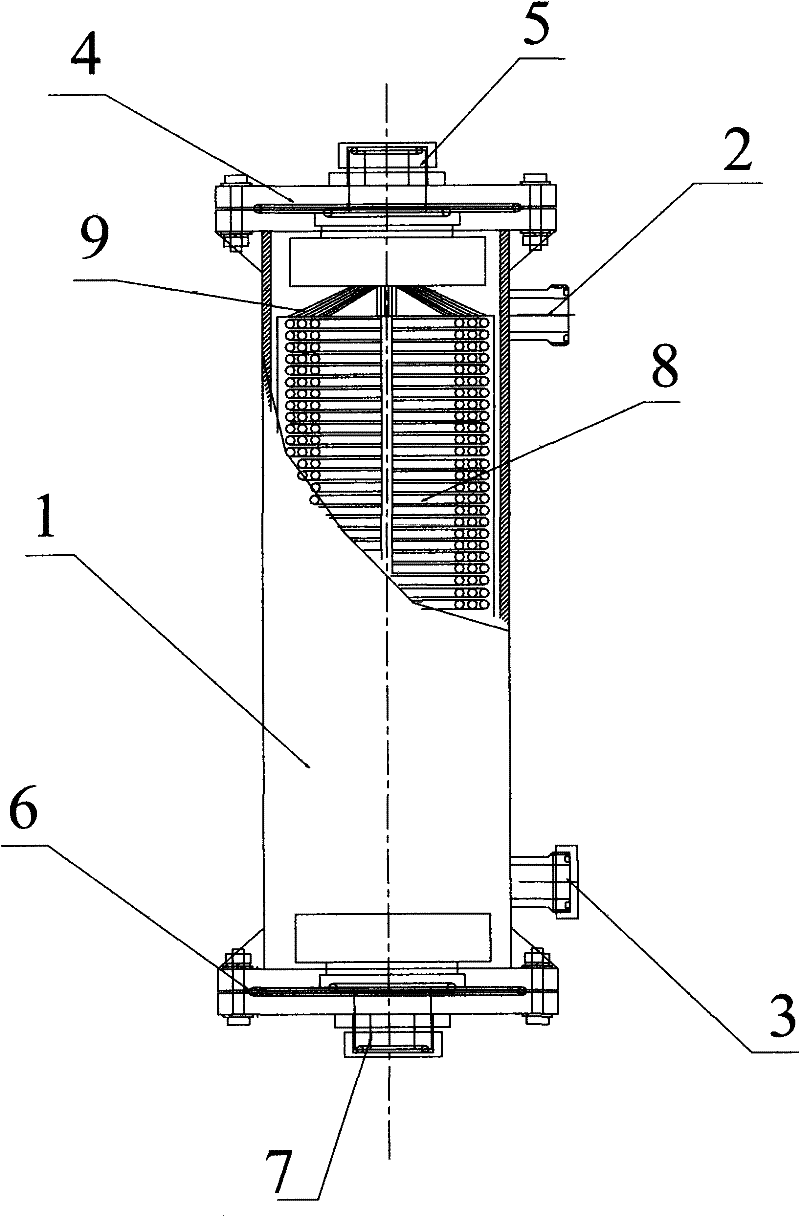

[0013] Such as figure 1 As shown, the Teflon cold and heat exchanger includes an outer tube 1, the upper end of the outer tube 1 is provided with a cold and hot water outlet 2, and the lower end of the outer tube 1 is provided with a cold and hot water inlet 3, and the cold and hot water inlet 2 , The hot and cold water outlet 3 communicates with the inner cavity of the outer pipe 1 . A Teflon tube bundle 8 is also arranged in the inner cavity of the outer tube 1 , and the Teflon tube bundle 8 is spirally arranged in the inner cavity of the outer tube 1 . The Teflon tube bundle 8 is welded by hundreds of Teflon capillary tubes 9 in parallel. The diameter of the Teflon capillary tubes 9 is less than or equal to 5mm. Decide. The top of the outer tube 1 is provided with an upper end cover 4, and the upper end cover 4 is provided with an exchanged medium outlet 5, and the bottom of the outer tube 1 is provided with a lower end cover 6, and the lower end cover 6 is provided with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com