Seawater desalting method

A technology for seawater and concentrated water, applied in chemical instruments and methods, seawater treatment, general water supply conservation, etc., can solve the problems of high energy consumption and low recovery rate of produced water, achieve low energy consumption, stable water quality and reduce organic matter The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

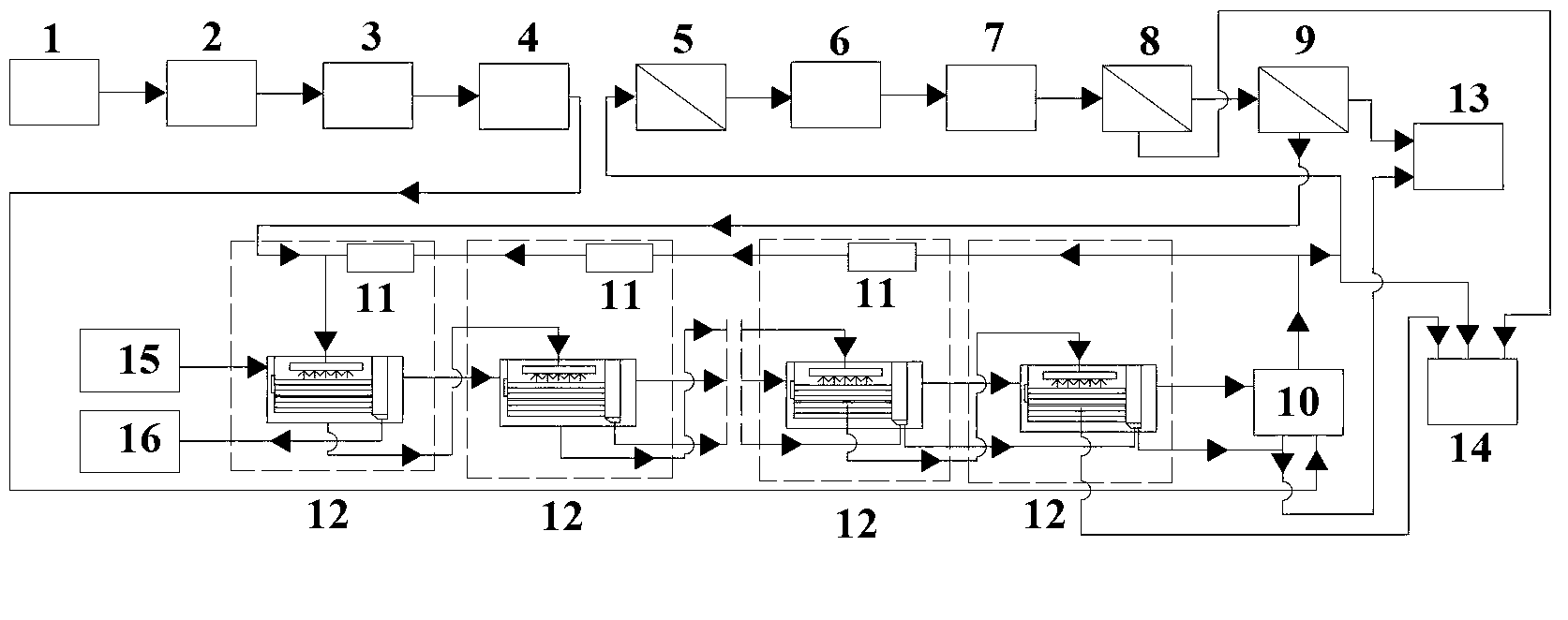

[0021] Example 1: Nanofiltration-reverse osmosis-low temperature multi-effect thermal membrane coupled seawater desalination

[0022]The seawater desalination system device of this embodiment includes a raw water pump 1, an ultrafiltration water inlet tank 2, a booster pump 3, a self-cleaning device 4, an ultrafiltration device 5, an intermediate water tank 6, a nanofiltration high-pressure pump 7, a nanofiltration device 8, Reverse osmosis device 9, MED device condenser 10, MED device preheater 11, MED device evaporator 12, mixed product water tank 13, mixed concentrated water discharge device 14, raw steam 15 and condensate 16; the inlet of raw water pump 1 and The sea water intake is connected, the outlet of the raw water pump 1 is connected to the ultrafiltration water inlet tank 2, and the flocculation occurs in the ultrafiltration water inlet tank 2, and the outlet of the ultrafiltration water inlet tank is connected to the water inlet of the booster pump 3, and the boost...

Embodiment 2

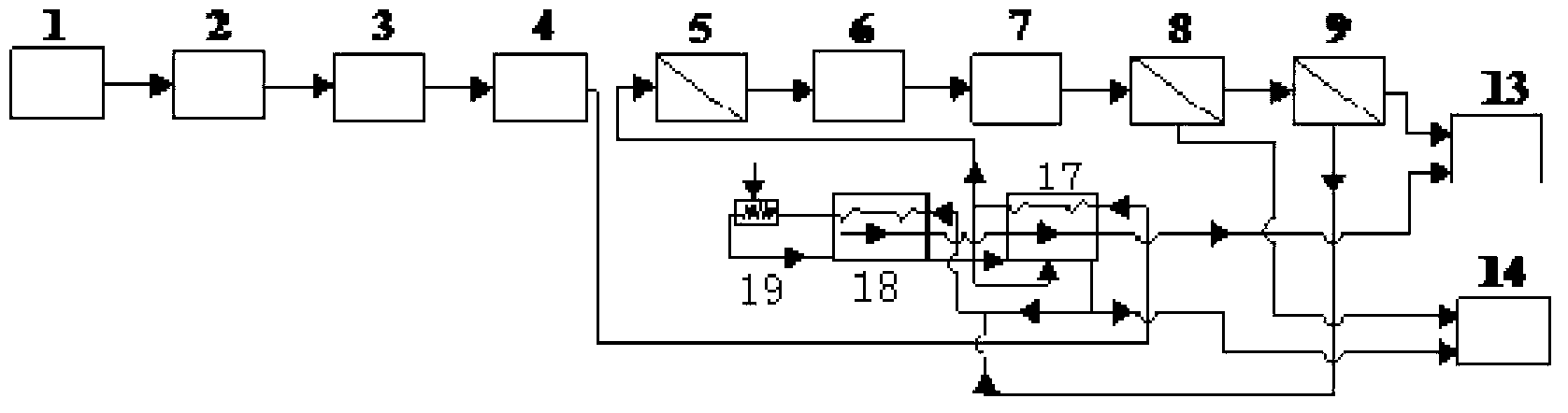

[0024] Example 2: Nanofiltration-reverse osmosis-low temperature multi-effect thermal membrane coupled seawater desalination

[0025] This embodiment adopts a nanofiltration seawater desalination system device with high ion selectivity, ultra-low pressure and large flux, and loose type. , concentrate water circulation, add acid and add antiscalant to adjust, keep the nanofiltration inlet water pressure as 1.8MPa, all the other components and connections are the same as in Example 1; under this operating condition, the nanofiltration membrane water production flux is 37L. m -2 h -1 , the recovery rate is as high as 60%; through analysis, there is no fouling phenomenon on the side of the nanofiltration concentrated water membrane at this time; 4 2- The true rejection rate of ions is 99%, for CO 3 2- The ion rejection rate is 78%, for Ca 2+ The ion rejection rate is 33%, the desalination rate of nanofiltration membrane elements to seawater is 14.5%, and the rejection rate t...

Embodiment 3

[0026] Example 3: Nanofiltration-reverse osmosis-low temperature multi-effect thermal membrane coupled seawater desalination

[0027] This embodiment adopts the system device of Embodiment 1 [see Figure 1(a)], the concentrated water is circulated, no acid and antiscalant are adjusted, and the nanofiltration water inlet pressure is maintained at 1.9MPa, and the nanofiltration membrane water production flux is 31L m -2 h -1 , the recovery rate is as high as 60%; through concentration polarization analysis, there is still no inorganic scaling on the surface of the nanofiltration concentrated water membrane at this time; 4 2- The true rejection rate of ions is 99%, for CO 3 2- The ion rejection rate is 77%, for Ca 2+ The ion rejection rate is 27%, the desalination rate of nanofiltration membrane elements to seawater is 13%, and the rejection rate to monovalent salts such as sodium chloride and potassium chloride is 9.5%. Content range≤50mg·L -1 The mixing ratio of reverse o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com