Electrolytic and nitrogen-doping one-step method for preparing petroleum coke-based carbon quantum dots

A technology of coke-based carbon quantum dots and petroleum coke, which is applied in the field of electrolytic preparation of petroleum coke-based carbon quantum dots and nitrogen doping, and can solve problems such as difficult large-scale preparation and cumbersome preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

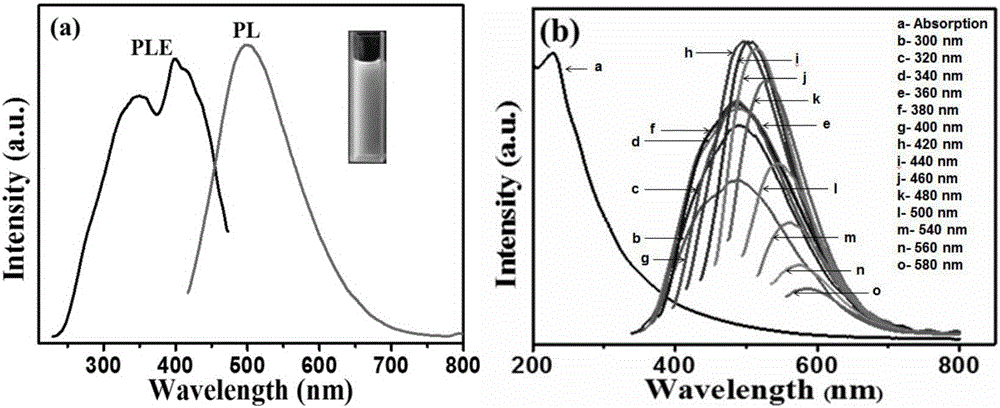

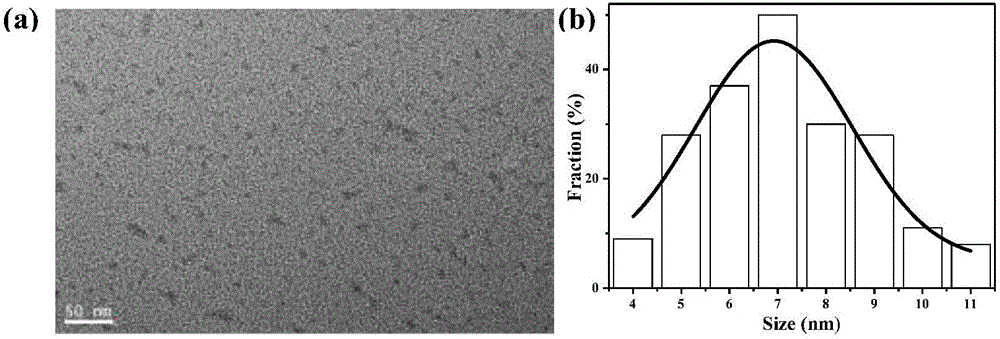

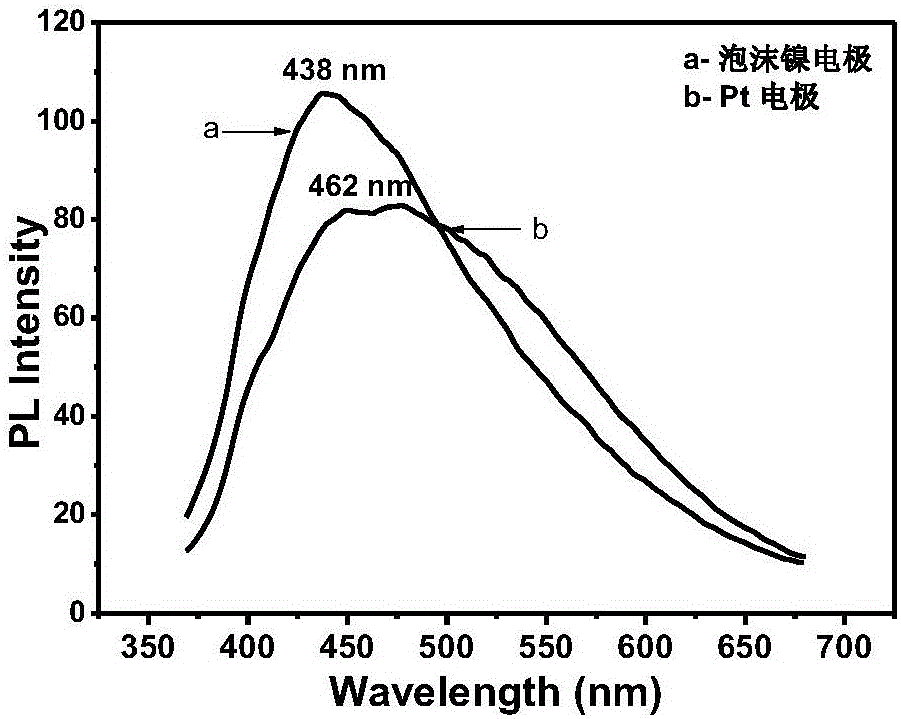

Embodiment 1

[0029] At 60°C, preheat the petroleum asphalt for 20 minutes. Weigh preheated petroleum asphalt 0.96 (16wt%), 1.5 (23wt%), 2.5g (33wt%) respectively, add appropriate amount of dichloromethane, stir until the asphalt is completely dissolved, then weigh 5.0g of petroleum coke respectively, and Mix the asphalt evenly, put it into a constant temperature water bath, evaporate most of the solvent, and obtain the electrode sheet raw material in black paste. The paste was extruded to obtain disc-shaped electrode sheets. The prepared electrode sheets were calcined in a tube electric furnace at 800° C. for 2 h under a nitrogen atmosphere. The prepared electrode sheet was used as the working electrode, the Pt electrode was used as the counter electrode, and 100mL of 0.5M NaOH solution was used as the electrolyte, at 220mA·cm -2 Electrolysis was carried out in the electrolytic cup for 12 hours under the current density to obtain an electrolyte solution containing carbon nanoparticles. ...

Embodiment 2

[0031] At 60°C, preheat the petroleum asphalt for 20 minutes. Weigh 1.5g of preheated petroleum asphalt, add appropriate amount of dichloromethane, stir until the asphalt is completely dissolved, then weigh 5.0g of petroleum coke, mix it with petroleum asphalt, put it in a constant temperature water bath, evaporate most of the solvent, and obtain Electrode sheet raw material in black paste. The paste was extruded to obtain disc-shaped electrode sheets. The prepared electrode sheets were calcined in a tube electric furnace at 500, 800, and 1000° C. for 2 h under a nitrogen atmosphere, respectively. The prepared electrode sheet was used as the working electrode, the Pt electrode was used as the counter electrode, and 100mL of 0.5M NaOH solution was used as the electrolyte, at 220mA·cm -2Under the current density, it was electrolyzed in the electrolytic cup for 24 hours to obtain an electrolyte solution containing carbon nanoparticles. After filtering through a 0.22 μm micropo...

Embodiment 3

[0033] At 60°C, preheat the petroleum asphalt for 20 minutes. Weigh 1.5g of preheated petroleum asphalt, add appropriate amount of dichloromethane, stir until the asphalt is completely dissolved, then weigh 5.0g of petroleum coke, mix with petroleum asphalt, put it in a constant temperature water bath, evaporate most of the solvent, and obtain Electrode sheet raw material in black paste. The paste was extruded to obtain disc-shaped electrode sheets. The prepared electrode sheet was calcined in a tube electric furnace at 800 °C for 2 h under a nitrogen atmosphere. The prepared electrode sheet was used as the working electrode, the Pt electrode was used as the counter electrode, and 100mL of 0.1M NaOH solution was used as the electrolyte, at 220mA·cm -2 Under the current density, electrolyze in the electrolytic cup for 8, 12, 24, 48, 72, 96, 120, and 144 hours, respectively, to obtain an electrolyte containing carbon nanoparticles. After filtering through a 0.22 μm microporou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com