Ultra-low temperature circulation refrigeration method employing injectors

A refrigeration method and ejector technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of low boiling point components condensing into liquids, low boiling point components boiling point limit, evaporation temperature rise, etc., to improve circulation performance, a wide range of applications, and the effect of reducing the compression ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

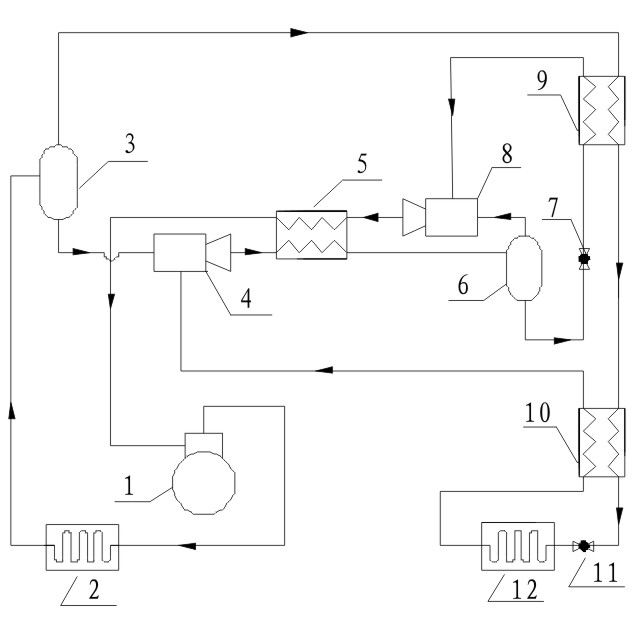

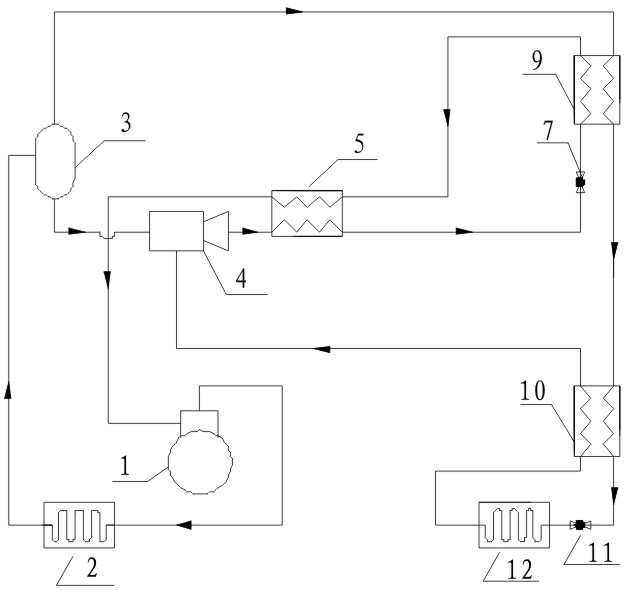

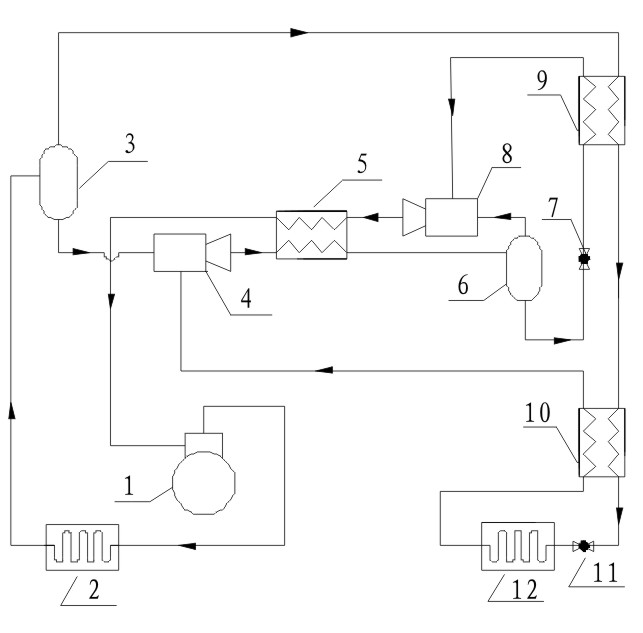

[0025] The refrigerating components involved in the ultra-low temperature cycle refrigeration method with an ejector in the present invention include a compressor 1, a condenser 2, a first gas-liquid separator 3, a first regenerator 5, a first throttling member 7, a condensation evaporation 9, a second regenerator 10, a second throttling element 11 and an evaporator 12, and the refrigeration component also includes a first ejector 4, a second ejector 8 and a second gas-liquid separator 6. Although the method of the present invention involves the above-mentioned refrigeration components common in the refrigeration industry, the connection relationship formed by the above-mentioned refrigeration components and the resulting cycle refrigeration process and effect are different. For this reason, the present invention consists of the above-mentioned refrigeration components and The ultra-low temperature cycle refrigeration process composed of refrigerant is as follows:

[0026] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com