Method for remediation of volatile organic compound and mercury compound contaminated soil

A technology for volatile organic compounds and complex pollution, applied in the field of soil pollution remediation, can solve the problems of low remediation efficiency, long treatment cycle, incomplete removal, etc., and achieve high removal efficiency, low difficulty, good economic and environmental benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

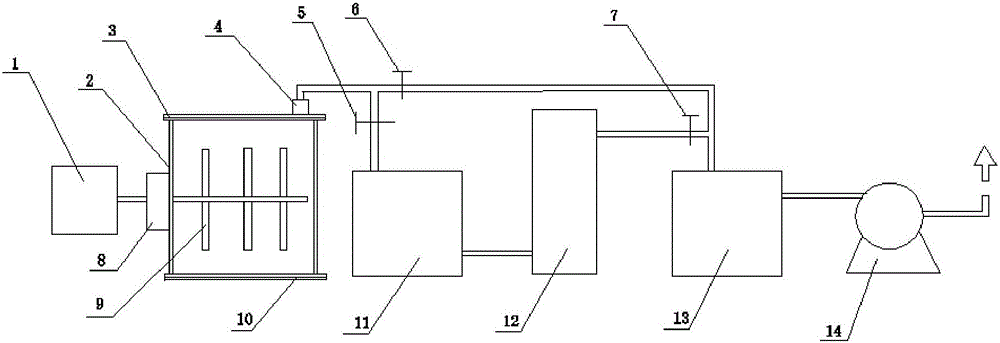

Method used

Image

Examples

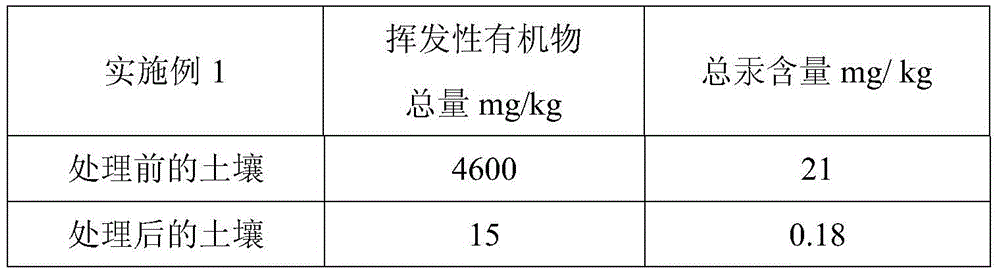

Embodiment 1

[0022] 1. Take 10kg of halogenated hydrocarbon and chromium composite polluted soil, and test the total volatile organic compounds and total mercury content; through crushing and screening, soil particles with good dispersion are obtained, with a particle size range of 1-15mm;

[0023] 2. Add ferric chloride to the soil particles at a ratio of 10g / kg; open the top cover of the reactor, put the soil particles into the closed reactor, open the No. 1 and No. 3 valves, close the No. 2 valve, and keep the vacuum The pressure of the reactor is 30Pa, the temperature of the reactor is controlled at 250°C by external heating, the temperature of the water cooler is controlled at 20°C, the motor is started to stir the soil, the treatment time is 5min, the mercury and a small amount of volatile organic compounds in the soil are passed through After the water cooler is cooled, it enters the mercury separator and is collected;

[0024] 3. Open the No. 2 valve, close the No. 1 and No. 3 valv...

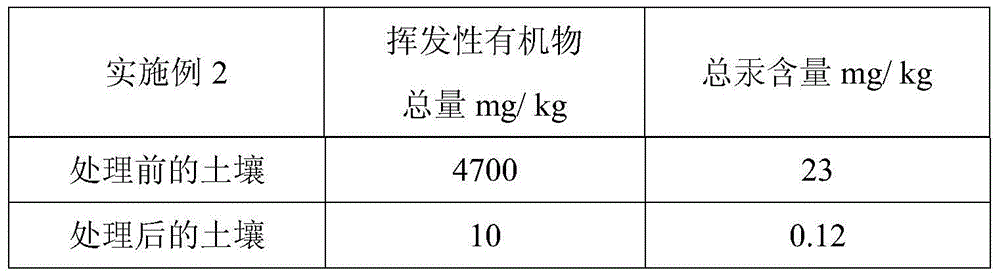

Embodiment 2

[0029] 1. Take 10kg of halogenated hydrocarbon and chromium composite polluted soil, and test the total volatile organic compounds and total mercury content; through crushing and screening, soil particles with good dispersion are obtained, with a particle size range of 1-15mm;

[0030] 2. Add ferric chloride to the soil particles at a ratio of 5g / kg; open the top cover of the reactor, put the soil particles into the closed reactor, open the No. 1 and No. 3 valves, close the No. 2 valve, and keep the vacuum The pressure of the reactor is 20Pa, the temperature of the reactor is controlled at 300°C by external heating, the temperature of the water cooler is controlled at 20°C, the motor is started to stir the soil, the treatment time is 10min, the mercury and a small amount of volatile organic compounds in the soil are passed through After the water cooler is cooled, it enters the mercury separator and is collected;

[0031] 3. Open the No. 2 valve, close the No. 1 and No. 3 valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com