P-type phosphorus-doped two-dimensional tungsten selenide semiconductor material and preparation method thereof

A tungsten diselenide and phosphorus doping technology, which is applied in the direction of binary selenium/tellurium compounds, metal selenide/telluride, etc., can solve the problems of small crystal domain size and low quality, reduce evaporation temperature and improve product quality. quality, growth-promoting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation method of the p-type phosphorus-doped two-dimensional tungsten diselenide semiconductor material of this embodiment includes the following steps:

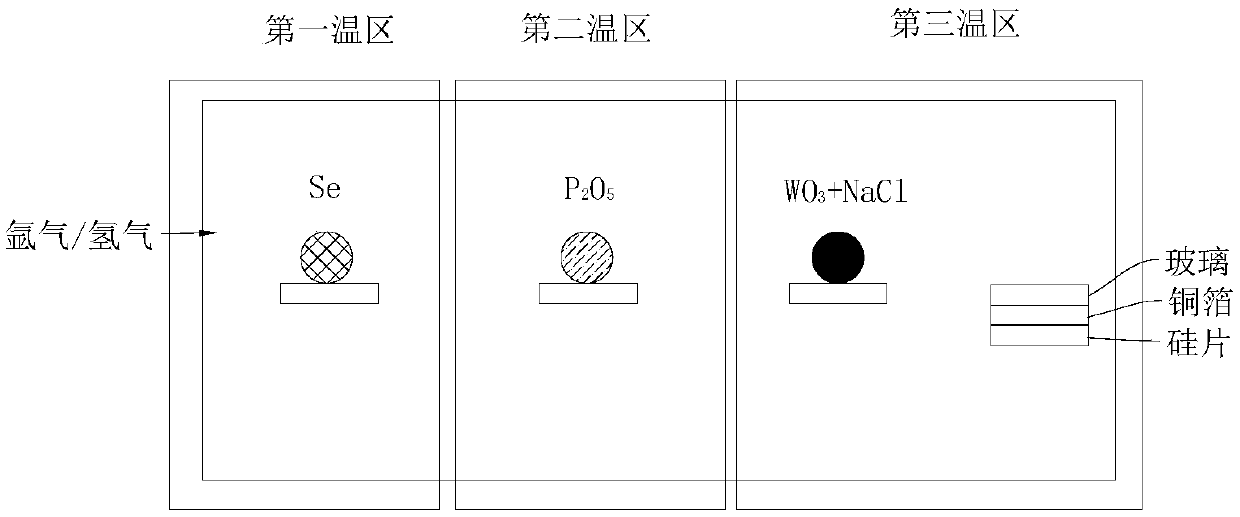

[0032] (1) 100 parts of Se element, P 2 O 5 30 copies and WO 3 30 parts of the mixture of NaCl and NaCl are respectively placed on the silicon wafer, and then put into the first temperature zone, the second temperature zone and the third temperature zone of the reaction furnace, and in the third temperature zone according to figure 1 Insert the growth substrate as shown, and the substrate is loaded with P 2 O 5 The distance between the silicon wafers is 5cm. Among them, WO 3 The mass ratio to NaCl is 5:1, and the substrate is stacked from bottom to top in the order of silicon wafer, copper foil and soda lime glass.

[0033] (2) Pass in 100sccm of argon gas, heat up the above three temperature zones to 100°C at a rate of 35°C / min, and hold for 10 minutes to remove the H that may be adsorbed in the CVD system 2 O; ...

Embodiment 2

[0036] The preparation method of the p-type phosphorus-doped two-dimensional tungsten diselenide semiconductor material of this embodiment includes the following steps:

[0037] (1) 50 parts of Se element, P 2 O 5 20 copies and WO 3 30 parts of the mixture of NaCl and NaCl are respectively placed on the silicon wafer, and then put into the first temperature zone, the second temperature zone and the third temperature zone of the reaction furnace, and in the third temperature zone according to figure 1 Insert the growth substrate as shown, and the substrate is loaded with P 2 O 5 The distance between the silicon wafers is 10cm. Among them, WO 3 The mass ratio to NaCl is 5:1, and the substrate is stacked from bottom to top in the order of silicon wafer, copper foil and soda lime glass.

[0038] (2) Pass in 100sccm of argon gas, heat up the above three temperature zones to 100°C at a rate of 35°C / min, and hold for 10 minutes to remove the H that may be adsorbed in the CVD system 2 O; T...

Embodiment 3

[0041] The preparation method of the p-type phosphorus-doped two-dimensional tungsten diselenide semiconductor material of this embodiment includes the following steps:

[0042] (1) 100 parts of Se element, P 2 O 5 10 copies and WO 3 30 parts of the mixture of NaCl and NaCl are respectively placed on the silicon wafer, and then put into the first temperature zone, the second temperature zone and the third temperature zone of the reaction furnace, and in the third temperature zone according to figure 1 Insert the growth substrate as shown, and the substrate is loaded with P 2 O 5 The distance between the silicon wafers is 20cm. Among them, WO 3 The mass ratio to NaCl is 5:1, and the substrate is stacked from bottom to top in the order of silicon wafer, copper foil and soda lime glass.

[0043] (2) Pass in 100sccm of argon gas, heat up the above three temperature zones to 100°C at a rate of 35°C / min, and hold for 10 minutes to remove the H that may be adsorbed in the CVD system 2 O;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com