Method for preparing perovskite solar cell on micron-sized large suede

A solar cell, micron-scale technology, applied in the field of solar cells, can solve the problems of reducing nucleation density, high film defects, and low efficiency, and achieve the effect of reducing nucleation density and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

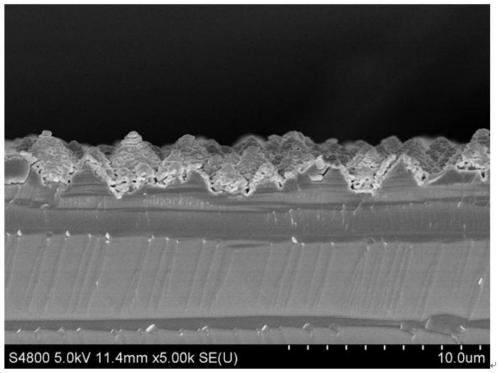

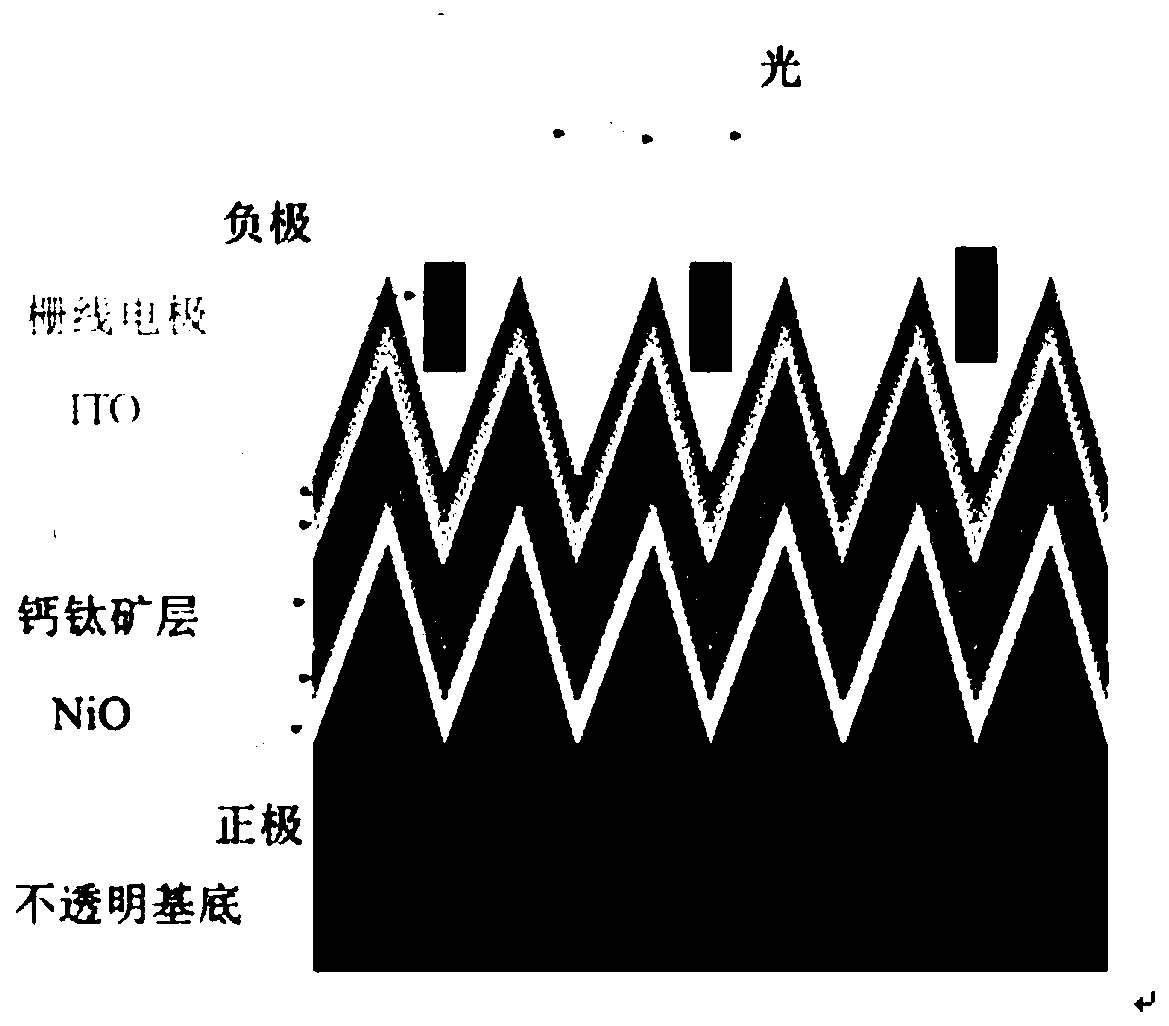

[0036] A method for preparing a perovskite solar cell on a micron-scale large textured surface, the schematic diagram of the cell structure is shown in image 3 shown, including the following steps:

[0037] S1. Prepare an Au electrode with a thickness of 200nm on an opaque textured substrate (textured silicon wafer) by thermal evaporation; prepare a hole transport layer (nickel oxide) on a transparent electrode with a thickness of 30nm by electron beam evaporation;

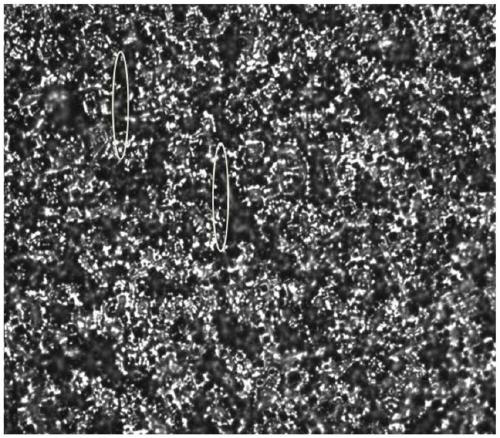

[0038] S2. On the nickel oxide hole transport layer, prepare a lead iodide-lead chloride film by co-evaporation, the evaporation rate ratio is 10:1, the thickness of the prepared film is 400nm, and the prepared iodide The lead-lead chloride film is placed in a vacuum chamber, and a certain amount of lead ligand solvent (tetramethylene sulfoxide) is placed in the vacuum chamber. The lead ligand solvent is volatilized by vacuuming, and its vapor and iodide The lead-lead chloride film reacts to form a ligand-lead i...

Embodiment 2

[0045] A method for preparing a perovskite solar cell on a micron-scale large textured surface, the schematic diagram of the cell structure is shown in Figure 4 shown, including the following steps:

[0046] S1. Prepare FTO transparent electrodes on transparent micro-scale suede glass by magnetron sputtering, with a thickness of 700nm; use electron beam evaporation to prepare a nickel oxide hole transport layer on the transparent electrodes, with a thickness of 30-40nm;

[0047]S2. On the nickel oxide hole transport layer, prepare a lead iodide-lead chloride film by co-evaporation, the evaporation rate ratio is 10:1, the thickness of the prepared film is 400nm, and the prepared iodide The lead-lead chloride film is placed in a vacuum chamber, and a certain amount of lead ligand solvent (tetramethylene sulfoxide) is placed in the vacuum chamber. The lead ligand solvent is volatilized by vacuuming, and its vapor and iodide The lead-lead chloride film reacts to form a ligand-le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com