Preparation method of large-size single-crystal graphene

A single crystal graphene, large size technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problem that large size single crystal graphene has no application value, reduce graphene nucleation density, growth problems such as low speed, to achieve the effect of low cost, large size and fast growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

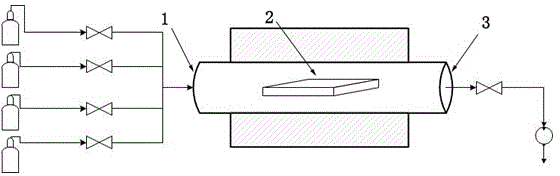

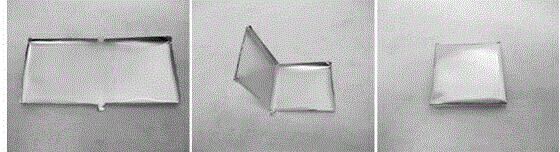

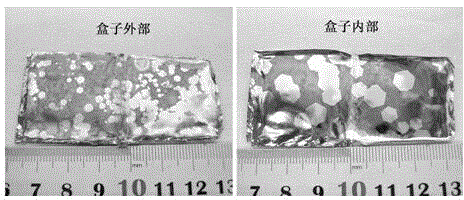

[0024] Such as figure 1 As shown, the present invention uses a horizontal reactor to grow graphene, and the two ends of the horizontal reactor are respectively provided with a gas inlet 1 and a gas outlet 4 . First, polycrystalline copper foil (thickness 125 μm, length×width=80mm×40mm) was ultrasonically cleaned in acetone, water and ethanol for 5 minutes respectively, and then ultrasonically cleaned in acetone, water and ethanol for 5 minutes respectively, and then Continue to put them into acetone, water, and ethanol in turn for ultrasonic cleaning for 5 minutes. After the cleaning is completed, the polycrystalline copper foil with a purity of 99.8% is made into a copper foil cavity (length × width × height = 35mm × 35mm × 3mm) (such as figure 2 ). The manufacturing method of the copper cavity structure is as follows: Fold the sides of the copper foil vertically up to 1.5mm high, and open a gap in the middle of the two longer vertical sides, and then fold the copper foil ...

Embodiment 2

[0027] Such as figure 1As shown, the present invention uses a horizontal reactor to grow graphene, and the two ends of the horizontal reactor are respectively provided with a gas inlet 1 and a gas outlet 4 . First, polycrystalline copper foil (thickness 125 μm, length×width=80mm×40mm) was ultrasonically cleaned in acetone, water and ethanol for 5 minutes respectively, and then ultrasonically cleaned in acetone, water and ethanol for 5 minutes respectively, and then Continue to put them into acetone, water, and ethanol in turn for ultrasonic cleaning for 5 minutes. After the cleaning is completed, the polycrystalline copper foil with a purity of 99.8% is made into a copper cavity structure (length × width × height = 35mm × 35mm × 3mm) (such as figure 2 ). The manufacturing method of the copper cavity structure is as follows: Fold the sides of the copper foil vertically up to 1.5mm high, and open a gap in the middle of the two longer vertical sides, and then fold the copper f...

Embodiment 3

[0030] Such as figure 1 As shown, the present invention uses a horizontal reactor to grow graphene, and the two ends of the horizontal reactor are respectively provided with a gas inlet 1 and a gas outlet 4 . First, put the copper foil (thickness 125 μm, length×width=150mm×70mm) into acetone, water and ethanol for 5 minutes for ultrasonic cleaning respectively, then put them into acetone, water and ethanol for 5 minutes respectively, and then continue to Put them into acetone, water, and ethanol for ultrasonic cleaning respectively for 5 minutes. After cleaning, the polycrystalline copper foil with a purity of 99.8% was made into a cavity structure (length×width×height=60mm×60mm×5mm). The manufacturing method of the copper foil cavity structure is as follows: Fold up the vertical sides of 1.5mm high around the copper foil vertically, and open a gap in the middle of the longer two vertical sides, and then fold the copper foil on both sides of the gap The vertical sides are co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com