Method for preparing molybdenum sulfide two-dimensional material by adopting MOCVD equipment

A two-dimensional material, molybdenum sulfide technology, applied in the direction of molybdenum sulfide, metal material coating process, gaseous chemical plating, etc., can solve the problem of difficult to control the growth direction of crystal nuclei, and achieve a controllable single-layer film thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A method for preparing MoS using MOCVD equipment 2 The method of (molybdenum sulfide) two-dimensional material includes the following steps:

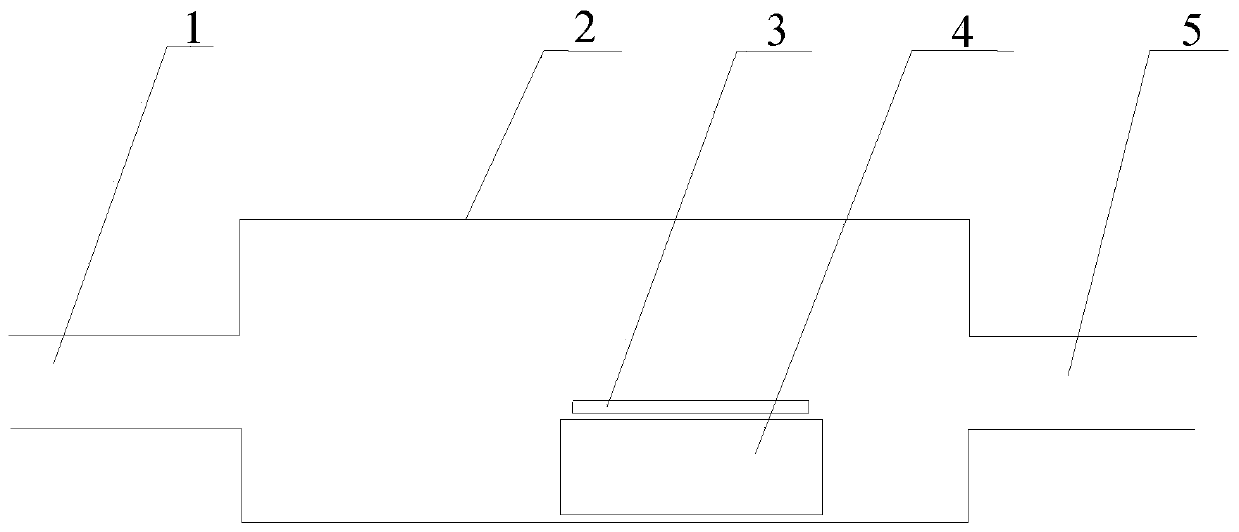

[0047] (1) Sapphire substrate 3 uses α-Al 2 O 3 Sapphire substrate (ZMKJ 2INCH A-axis), without any pretreatment, such as figure 1 Shown

[0048] (2) The Sapphire substrate is transferred to the quartz table 4 in the MOCVD chamber 2, the initial pressure in the chamber is controlled at 90 Torr, and N is always passed through the gas source inlet 1 in the chamber. 2 20slm;

[0049] (3) The reaction is carried out by chemical vapor deposition: slowly increase the chamber to a growth temperature of 1000°C in 10 minutes, and keep it at a constant temperature for 5 minutes; first pass in 0.1slm H 2 S gas source for 10 minutes to passivate the surface of Sapphire substrate; then pass in 5×10 -5 slm Mo(CO) 6 Air source while maintaining 0.1slm H 2 S gas source is introduced, MoS is performed at a pressure of 90 Torr and a growth temperature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com