Pretreatment method of graphene growth substrate

A growth substrate and pretreatment technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of lowering physical properties and reducing the nucleation density of graphene, so as to reduce the nucleation density and reduce the roughness of the substrate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

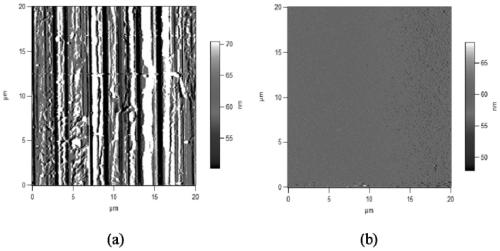

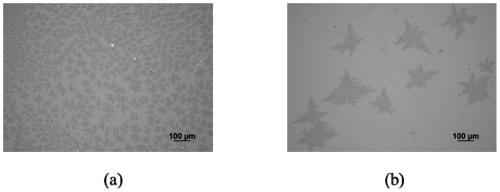

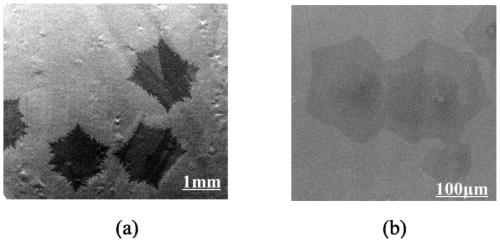

[0018] The invention provides a pretreatment method for graphene growth substrates. Taking copper foil as the research object, it is initially polished, and then placed in a tube furnace for annealing. The annealed substrate is taken out from the furnace and again It is polished, then placed on a heating table to be heated and oxidized, and finally graphene is grown by chemical vapor deposition.

[0019] First, the first electrochemical polishing is carried out on the copper substrate to initially reduce the roughness of the substrate surface. The voltage of the electrochemical polishing is 10V, and the polishing time is 20-180 seconds. The composition of the polishing liquid is: phosphoric acid 100mL, ethanol 100mL, isopropyl Alcohol 20mL, deionized water 200mL, urea 2g.

[0020] Place the polished copper substrate in a tube furnace for annealing, so that impurities inside the copper substrate are precipitated to the surface of the substrate. The annealing time is 0.5-12 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com