Carrier for controlling graphene crystal nucleus growth

A technology of crystal nucleus growth and graphene, which is applied in the field of vehicles to control the growth of graphene crystal nuclei, and can solve problems such as high density, uncontrollable crystal chips, and small graphene film crystal nuclei

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

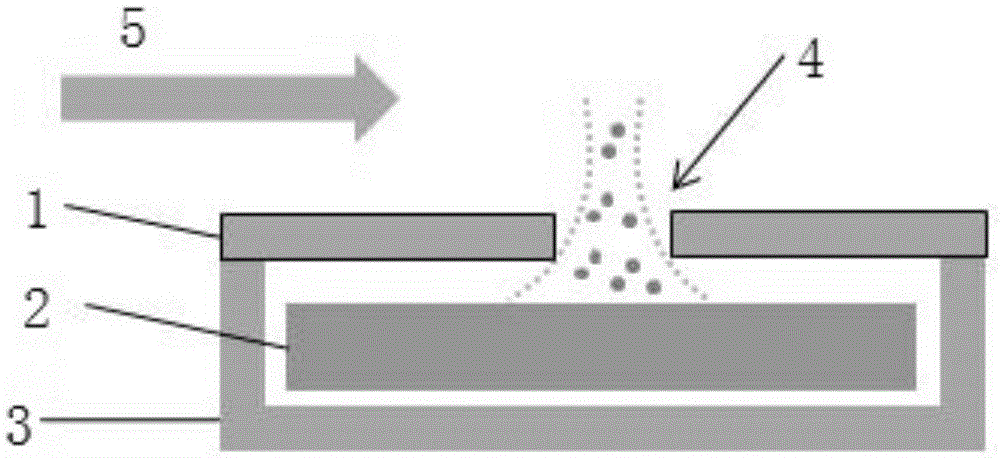

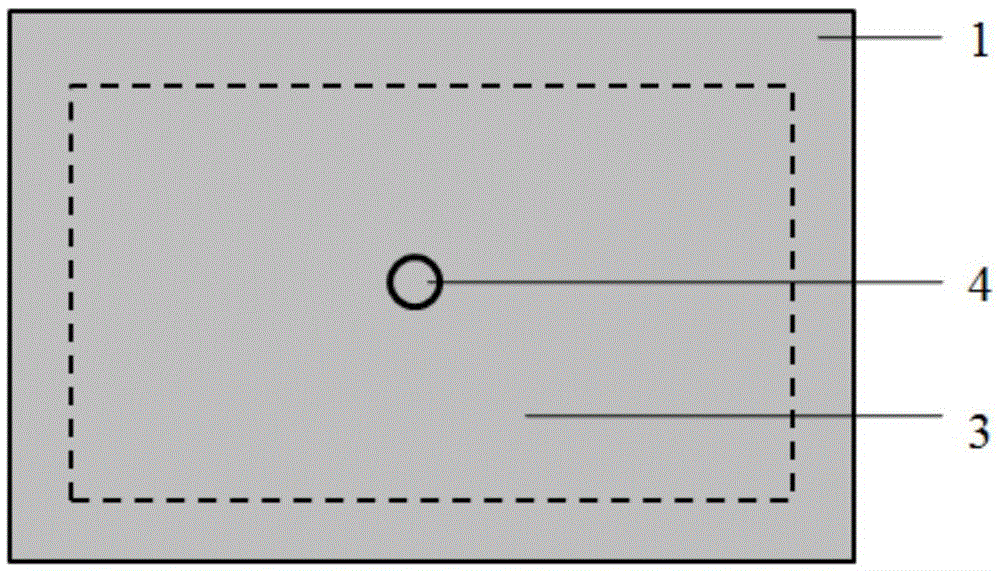

[0040] A carrier for controlling the growth of graphene crystal nuclei, such as figure 1 with figure 2 As shown, it is a high temperature resistant graphite carrier, including a loam cake 1, a box and a straight metal substrate 2 for growing graphene, the metal substrate 2 is copper foil, the size of the metal substrate is smaller than the size of the base, and the loam cake There is a small hole 4 on the top, the diameter of the small hole is 0.5mm, the upper cover and the box are made of graphite; the lower surface of the upper cover is straight, the box includes the base 3 and surrounding walls, the upper end of the box is open, the base 3 is a flat bottom wall. The straight metal base used for growing graphene is placed on the base of the box, and the distance between the metal base and the lower surface of the upper cover on the box is 2mm, and the surrounding walls around the box are of equal height. The cover and the upper edge of the surrounding wall around the box a...

Embodiment 2

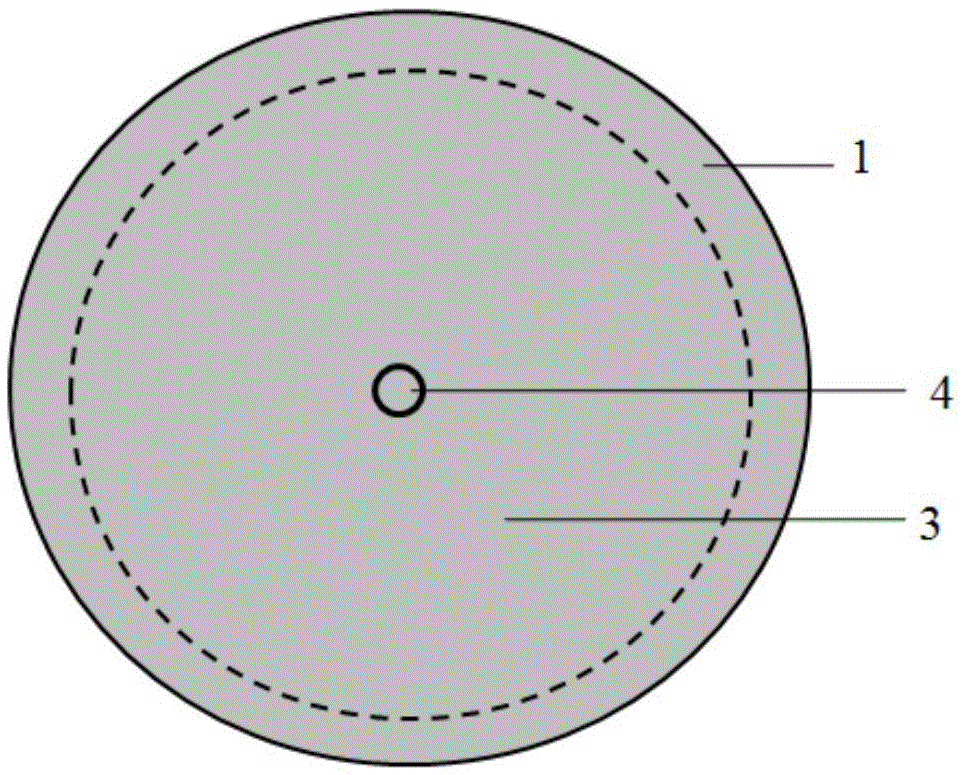

[0043] A carrier for controlling the growth of graphene crystal nuclei, such as image 3As shown, it is a high-temperature-resistant carrier, including a loam cake 1, a box and a flat metal base 2 for growing graphene. The metal base 2 is copper foil, and the size of the metal base is smaller than the size of the base. There is a small hole 4 with a diameter of 1 mm. Both the upper cover and the box are made of quartz; the lower surface of the upper cover is straight, and the box includes a base 3 and surrounding walls. A flat bottom wall, a flat metal base for growing graphene is placed on the base of the box, and the distance between the metal base and the lower surface of the upper cover on the box is 1.6mm, and the surrounding walls around the box are of equal height, and the upper cover It fits the upper edge of the wall around the box; the base of the carrier is circular, and its size matches the diameter of the quartz tube of the CVD tube furnace. The carrier containing...

Embodiment 3

[0045] A carrier for controlling the growth of graphene crystal nuclei is a high-temperature-resistant carrier, including a loam cake 1, a box and a straight metal substrate 2 for growing graphene, the metal substrate 2 is Ru foil, and the metal substrate The size is smaller than the size of the base. There are 9 small holes 4 on the upper cover. The small holes are an array of 3*3. The diameter of the small holes is 2mm. Both the upper cover and the box are made of silicon nitride; Straight, the box includes a base 3 and surrounding walls, the upper end of the box is open, the base 3 is a flat bottom wall, the straight metal base for growing graphene is placed on the base of the box, and the metal base and cover are placed on the box The distance between the lower surface of the upper cover and the lower surface of the box is 1mm, the surrounding walls around the box are of the same height, and the upper cover and the upper edge of the surrounding walls around the box are atta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com