Self-supporting gallium nitride single crystal based on HVPE and preparation method thereof

A gallium nitride single crystal, self-supporting technology, applied in the semiconductor field, can solve problems such as the effect of absorbing stress is not very significant, does not reach the heterogeneous substrate, and the process control performance is poor, so as to reduce the nucleation density and improve the crystal Quality, the effect of stress reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

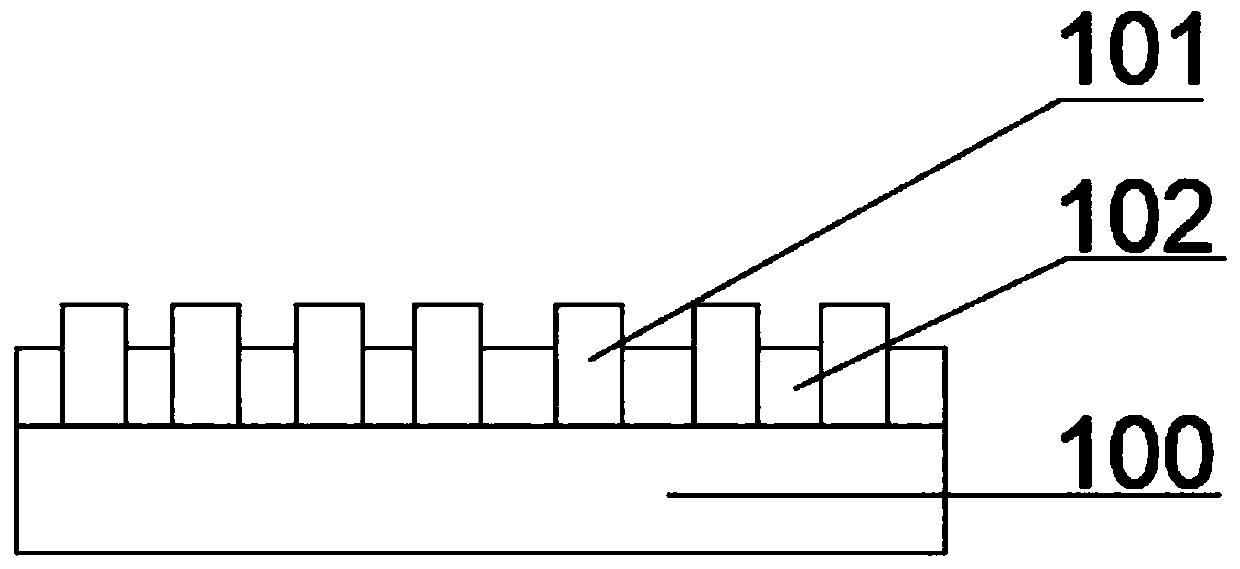

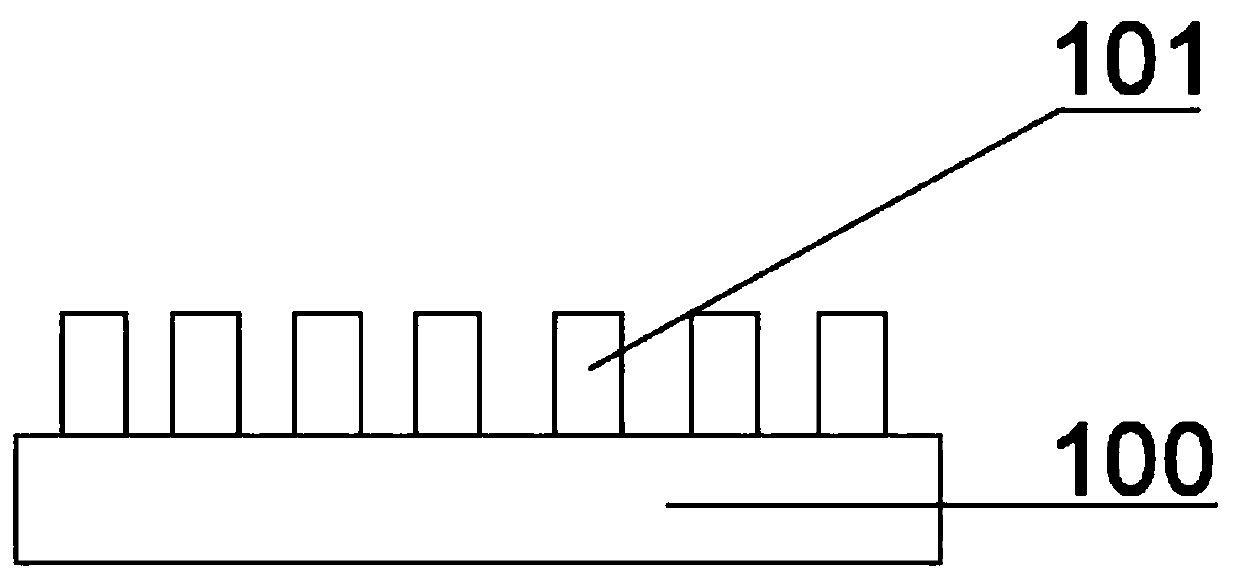

[0041] according to Figure 1-5 , the present invention provides a self-supporting gallium nitride single crystal based on HVPE, the preparation method of the self-supporting gallium nitride single crystal based on HVPE comprises the following steps:

[0042] (1) Provide a substrate, and perform cleaning and nitriding treatment on the surface of the substrate.

[0043] (2) growing GaN crystal nuclei on the surface of the substrate at low temperature, while HCl and NH3 form NH4Cl solids, competing with GaN crystal nuclei to cover the substrate;

[0044] (3) The temperature is increased to above 1000°C for annealing treatment to improve the quality of GaN crystal nuclei;

[0045] (4) two-dimensionally growing a GaN layer on the GaN crystal nucleus at medium and high temperature;

[0046] (5) Continuously growing a GaN single crystal at high temperature on the GaN layer;

[0047] (6) Lowering the temperature and peeling off the GaN single crystal from the substrate to form a s...

Embodiment 2

[0058] The HVPE-based self-supporting gallium nitride single crystal provided in this example is roughly the same as the method provided in Example 1, except that the low temperature range of step (2) is 370-440°C, V / III is 200, The coverage rate of the GaN crystal nucleus is 56%, and its growth thickness is 60-80nm.

[0059] As a preferred setting of the embodiment of the present invention, the GaN layer in step (4) is two-dimensionally grown at a medium and high temperature of 800-1100°C, V / III is set to 10, the growth rate is 20um / hr, and the thickness is 8-10um.

[0060] In addition, the technical features disclosed in Embodiment 1 are also applicable to this embodiment, and other technical features already disclosed in Embodiment 1 will not be repeated here.

Embodiment 3

[0062] The HVPE-based self-supporting gallium nitride single crystal provided in this example is roughly the same as the method provided in Example 1, except that the low temperature range of step (2) is 440-500°C, V / III is 200, The coverage rate of the GaN crystal nucleus is 65%, and its growth thickness is 70-100nm.

[0063] As a preferred setting of the embodiment of the present invention, the GaN layer in step (4) is two-dimensionally grown at a medium and high temperature of 950-1100°C, V / III is set to 20, the growth rate is 30um / hr, and the thickness is 6-10um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com