Low nucleation density graphene single crystal preparation method based on cuprous oxide film substrate

A technology of cuprous oxide and nucleation density, which is applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve the problems that the theoretical value cannot be reached, and the electrical properties of graphene need to be improved, so as to achieve the nucleation density Reduced, easy control of single crystal density, effect of increasing single crystal size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A method for preparing a graphene single crystal with low nucleation density based on a cuprous oxide thin film substrate, comprising the following steps:

[0027] (1) Preparation of cuprous oxide thin film: place the copper foil before graphene single crystal growth after polishing in an annealing furnace, feed oxygen-containing air and heat for a period of time, so that the surface of copper foil for graphene single crystal growth is formed thin copper oxide layer, and then soak the obtained copper oxide film in a hydrazine hydrate solution to obtain a substrate whose surface is cuprous oxide. The heating temperature of the copper foil in oxygen-containing air is 150-500°C. The heating time of the copper foil in oxygen-containing air is 1-120min. The volume percentage of oxygen contained in the oxygen-containing air is 10%-100%. The volume percent concentration of the hydrazine hydrate solution is 1%-30%. The soaking time of the hydrazine hydrate solution is 10-60 ...

Embodiment 1

[0030] Place the polished copper foil before graphene single crystal growth in an annealing furnace, heat it to 250°C with oxygen-containing air, and keep it for 30 minutes to form a thin oxide layer on the surface of the copper foil for graphene single crystal growth, cool down and take it out sample. Soak the obtained sample in 5% hydrazine hydrate solution by volume for 30 minutes, take it out and blow dry.

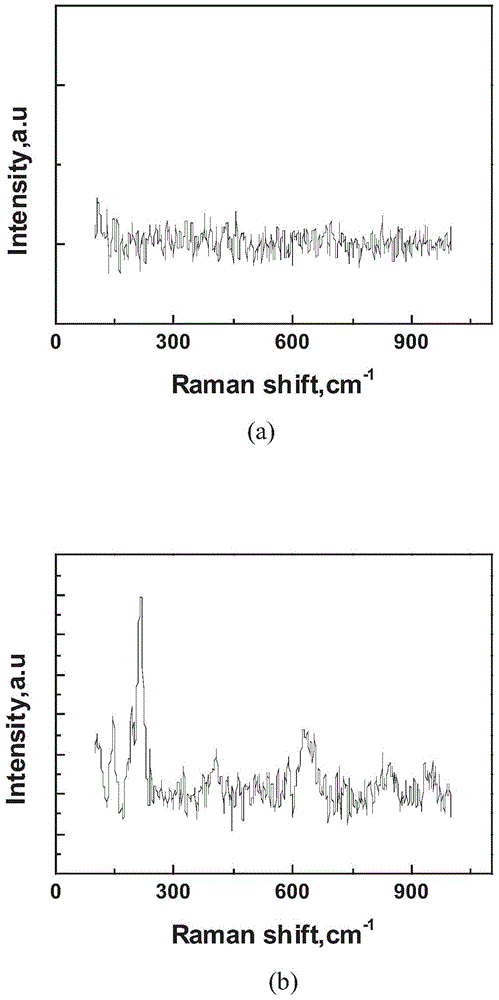

[0031] figure 1 A and b are the Raman images of the substrate copper and the cuprous oxide film substrate after treatment with hydrazine hydrate, respectively. figure 1 Peaks 216 and 626cm appear in b -1 It shows that the surface of the substrate is a cuprous oxide film. In the experiment, cuprous oxide derived from copper oxide was reduced in hydrazine hydrate solution. Therefore, the prepared cuprous oxide content is related to the concentration and time of soaking the sample in the hydrazine hydrate solution.

Embodiment 2

[0033] Put the cuprous oxide thin film substrate and the substrate copper foil grown by traditional CVD into the reaction chamber, heat to 1050°C, feed hydrogen gas so that the flow ratio of argon gas and hydrogen gas is 5:1, and anneal for half an hour. Then, 1.5 sccm of mixed methane (0.05% methane + 99.5% argon), 20 sccm of hydrogen, and 1000 sccm of argon were introduced, and the growth time was 25 min. The samples were compared by scanning electron microscopy.

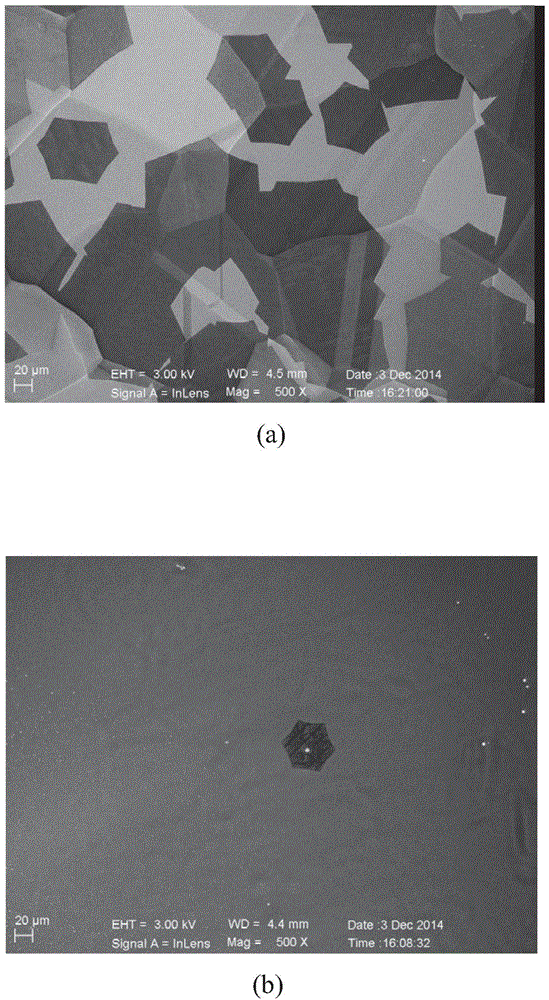

[0034] figure 2 In the figure is the optical microscope result after the substrate copper foil and cuprous oxide thin film substrate grown by traditional CVD are treated and grown in Example 2. In order to resolve the graphene core substrate, the sample was heated to 150 °C in air for 10 min. like figure 2 The hexagonal regions in a and 2b are graphene single crystals. It can be seen from the comparison that the nucleation density of graphene directly grown by CVD on the copper foil substrate is high, while ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com