Preparation method of monolayer and mono-crystal graphene

A single-crystal graphene, single-layer technology, applied in the field of nanomaterials, can solve the problems of unstable electronic properties of graphene, hindering electron transportation, etc., and achieve the effect of inhibiting a large number of nucleation, reducing nucleation density, and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of single-layer single-crystal graphene, comprising the following steps:

[0033] Preparation stage: Acidify the polycrystalline copper foil: ultrasonically clean the polycrystalline copper foil with glacial acetic acid, ethanol, and deionized water for 5 minutes, and then dry the polycrystalline copper foil with nitrogen;

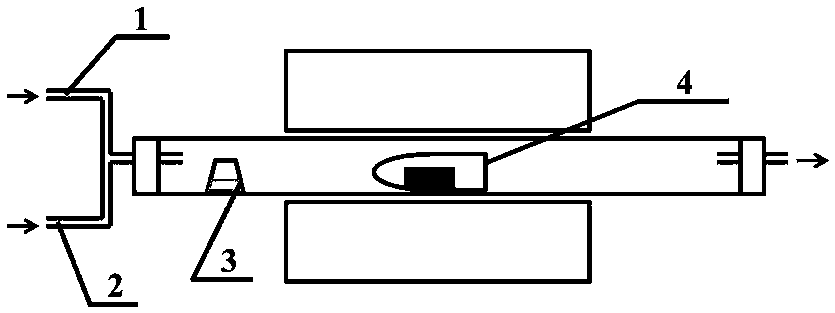

[0034] Step a: Put the acidified polycrystalline copper foil into a semi-closed quartz test tube, place the polycrystalline copper foil at the mouth of the semi-closed quartz test tube, put the semi-closed quartz test tube into the constant temperature zone of the tube furnace, and install Put the weighing bottle with polystyrene into the end of the tube furnace near the air inlet. The distance between the weighing bottle and the semi-closed quartz test tube is 34.5cm. After the tube furnace is evacuated, argon gas is introduced. This step is repeated three times to remove the tube. The air in the type furnace makes the argon ga...

Embodiment 2

[0040] A preparation method of single-layer single-crystal graphene, comprising the following steps:

[0041] Preparation stage: Acidify the polycrystalline copper foil: ultrasonically clean the polycrystalline copper foil with 10% hydrochloric acid solution, ethanol, and deionized water for 8 minutes, and then dry the polycrystalline copper foil with nitrogen;

[0042] Step a: Put the acidified polycrystalline copper foil into a semi-closed quartz test tube, place the polycrystalline copper foil at the mouth of the semi-closed quartz test tube, put the semi-closed quartz test tube into the constant temperature zone of the tube furnace, and install Put the weighing bottle with polystyrene into the end of the tube furnace near the air inlet. The distance between the weighing bottle and the semi-closed quartz test tube is 32.5cm. After the tube furnace is evacuated, argon gas is introduced. This step is repeated three times to remove the tube. The air in the type furnace makes t...

Embodiment 3

[0047] A preparation method of single-layer single-crystal graphene, comprising the following steps:

[0048] Preparation stage: Acidify the polycrystalline copper foil: ultrasonically clean the polycrystalline copper foil with glacial acetic acid, ethanol, and deionized water for 7 minutes respectively;

[0049] Step a: Put the acidified polycrystalline copper foil into a semi-closed quartz test tube, put the semi-closed quartz test tube into the tube furnace, and put the weighing bottle with polystyrene into the tube furnace near the air inlet At one end of the tube, the weighing bottle is 40cm away from the semi-closed quartz test tube, and argon is introduced into the tube furnace so that the argon is filled with the tube furnace, and the argon flow rate is 500 sccm;

[0050] Step b: Continuously inject argon gas, heat the polycrystalline copper foil to 800°C, and then keep the temperature at a constant temperature for 30 minutes;

[0051] Step c: stop feeding argon, star...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com