Preparation method of erbium-doped molybdenum disulfide film

A molybdenum disulfide, thin film technology, applied in gaseous chemical plating, metal material coating process, coating and other directions to achieve the effect of reducing the initial nucleation density and gas concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A kind of preparation method of erbium-doped molybdenum disulfide film of the present invention comprises the following steps:

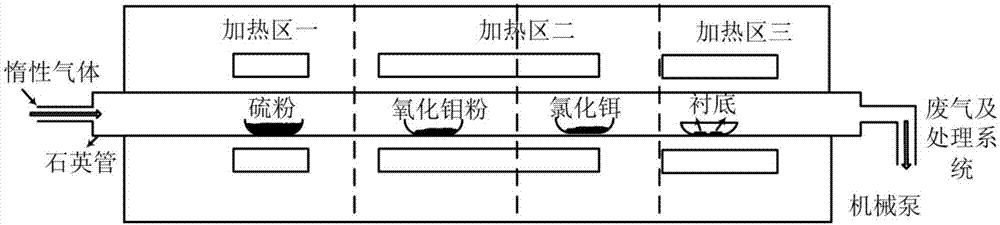

[0026] Step 1. Using a chemical vapor deposition (CVD) system with three temperature zones, place the sulfur powder in the first temperature zone; place the molybdenum trioxide powder and erbium chloride powder in the second temperature zone; place the substrate at the bottom of the crucible with a cover , and then place the crucible in three temperature zones;

[0027] Step 2, vacuumize the inside of the quartz tube, and pass carrier gas into the quartz tube for cleaning;

[0028] Step 3, the first heating stage: continue to pass the carrier gas, heat the second temperature zone to 150-350°C, and keep it for 60-180min; heat the third temperature zone to 150-350°C, and keep it for 60-180min;

[0029] Step 4, the second heating stage: After inflating the quartz tube to make the internal pressure of the quartz tube equal to atmospheric pressure...

Embodiment 1

[0045] Step 1, use figure 1 In the shown three-temperature zone chemical vapor deposition (CVD) system, 100 mg of sulfur powder with a purity of 99.99% is placed in a corundum boat and placed in a temperature zone; The erbium powder is placed in the corundum boat and placed in the second temperature zone; the mass of the molybdenum trioxide powder and the erbium chloride powder are both 5 mg; the C-face sapphire or silicon oxide / silicon is selected as the substrate, and the substrate is cleaned; After drying, place it in a quasi-closed crucible, and then place the crucible in three temperature zones;

[0046] Step 2, use a mechanical pump to pump the background vacuum in the quartz tube to below 1Pa, pass an inert carrier gas into the quartz tube: high-purity nitrogen gas, the flow rate of the carrier gas is 100ccm, and the flowing gas is cleaned several times;

[0047] Step 3, the first heating stage: continue to pass the carrier gas, heat the second temperature zone to 150°...

Embodiment 2

[0053] Step 1, use figure 1 In the three-temperature zone chemical vapor deposition (CVD) system shown, 300 mg of sulfur powder with a purity of 99.99% is placed in a corundum boat and placed in a temperature zone; The erbium powder is placed in the corundum boat and placed in the second temperature zone; the mass of the molybdenum trioxide powder is 10mg, and the mass of the erbium chloride powder is 5mg; the C-plane sapphire or silicon oxide / silicon is selected as the substrate, and the substrate is cleaned ;Place it in a quasi-closed crucible after drying, and then place the crucible in three temperature zones;

[0054] Step 2, use a mechanical pump to pump the background vacuum in the quartz tube to below 1Pa, pass an inert carrier gas into the quartz tube: high-purity nitrogen gas, the flow rate of the carrier gas is 300ccm, and the flowing gas is cleaned several times;

[0055] Step 3, the first heating stage: continue to pass the carrier gas, heat the second temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com