Preparation method of molybdenum sulfide two-dimensional material growing on Sappire substrate

A sapphire substrate and two-dimensional material technology, which is applied in the field of preparation of two-dimensional molybdenum sulfide materials, can solve problems such as difficult sample peeling to a single layer, irregular sample shape and size, preparation and performance impact, etc., and the growth conditions can be achieved. Variable controllable, large sample size, improved shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Using α-Al 2 o 3 Sapphire substrate (ZMKJ 2INCH A-axis), without any pretreatment, the substrate morphology is as follows figure 1 shown;

[0036] (2) Transfer the Sapphire substrate into the quartz table in the MOCVD cavity, the pressure in the cavity is controlled at 20Torr, and the cavity is always filled with N 2 20slm;

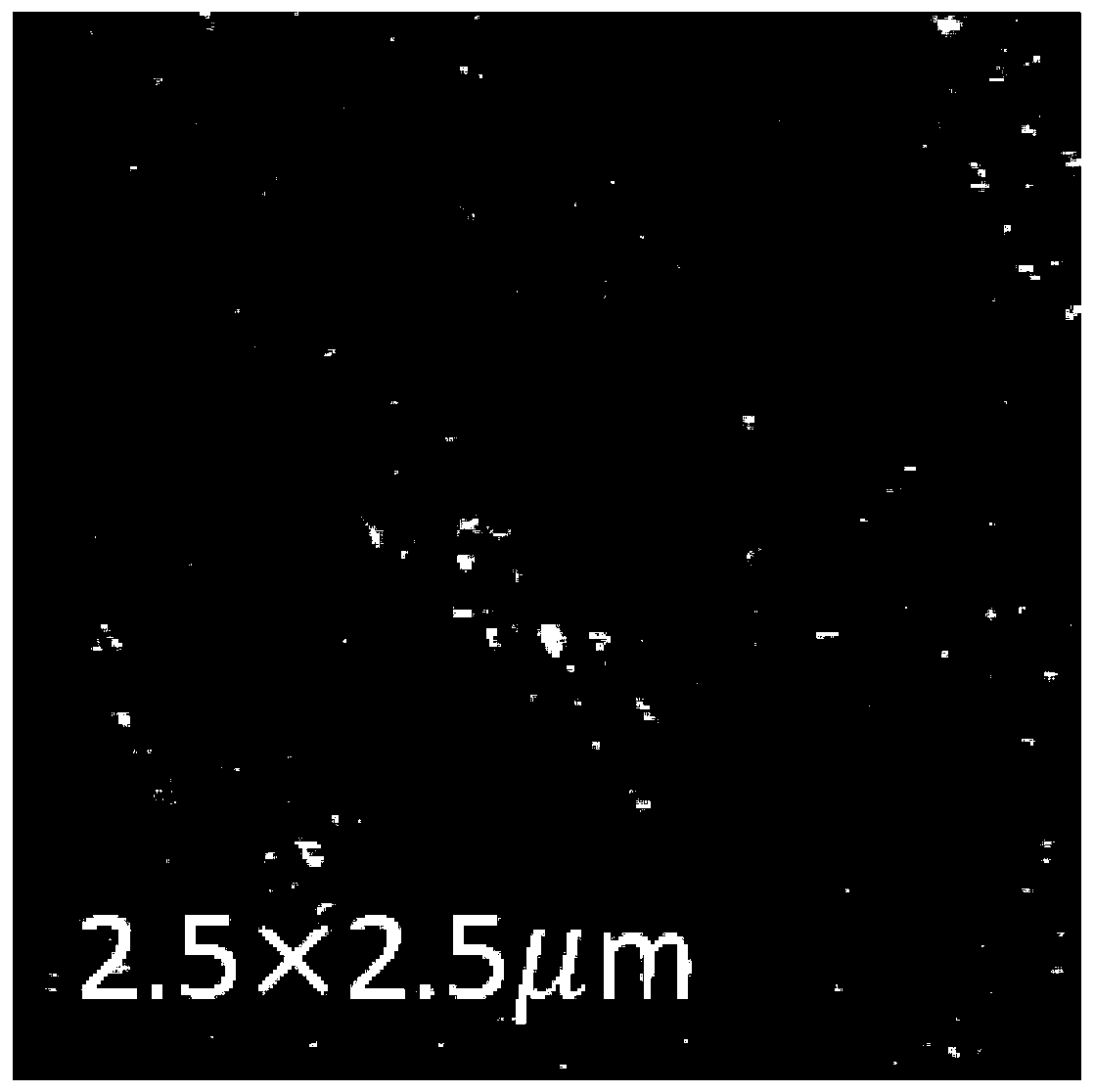

[0037] (3) Reaction by chemical vapor deposition method: Slowly increase the growth temperature in the MOCVD chamber to 1000°C in 10 minutes, and keep the temperature at a constant temperature for 5 minutes; first pass 0.1slm H 2 S gas source for 10 minutes to passivate the surface of the Sapphire substrate, the morphology effect is as follows figure 2 shown; then pass through 5×10 -5 slm Mo(CO) 6 gas source while maintaining H 2 Injection of S, MoS at a growth temperature of 1000°C 2 Constant temperature growth for 5 minutes; after the constant temperature growth is completed, first stop the Mo(CO) 6 Gas source, keep feeding H 2 S ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com