Gallium nitride base film on flexible polyimide substrate and preparing method of gallium nitride base film

A technology based on polyimide and gallium nitride, which is applied in the direction of gaseous chemical plating, semiconductor/solid-state device manufacturing, coating, etc., and can solve the problems of not being able to block the diffusion of water and oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific embodiments of the present invention will be further described below with reference to the drawings and technical solutions.

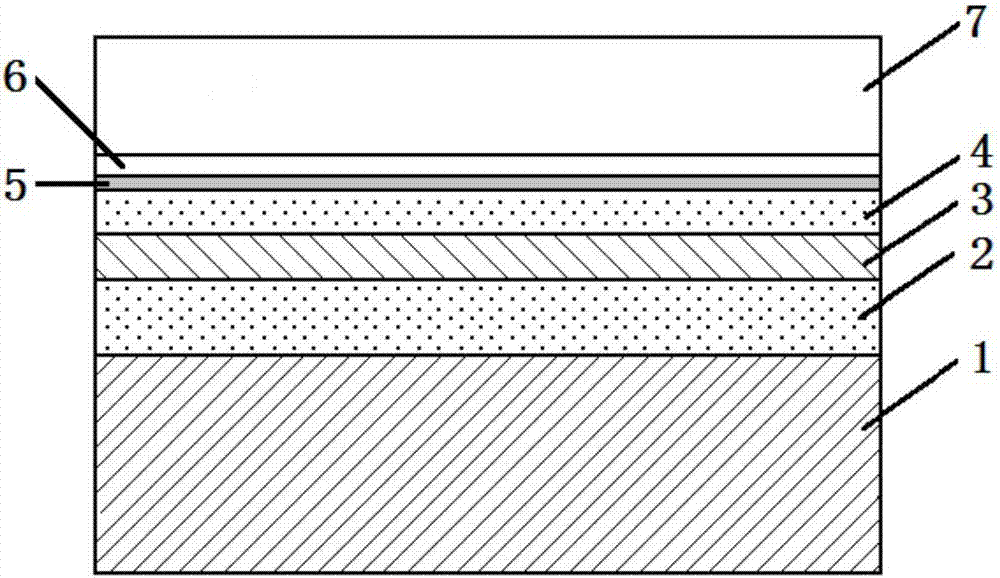

[0042] One of the embodiments, as attached figure 1 , 2 and 3.

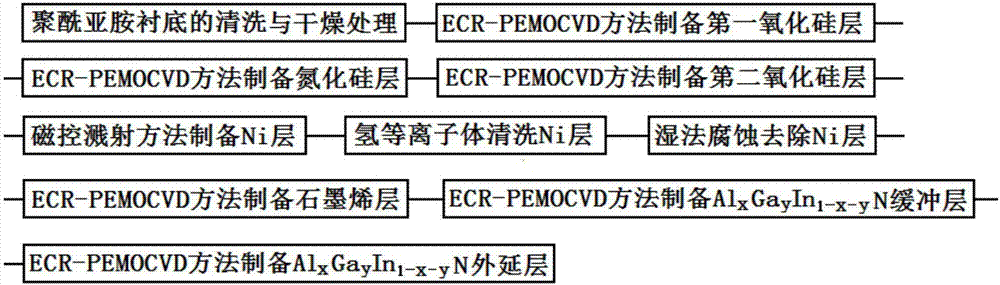

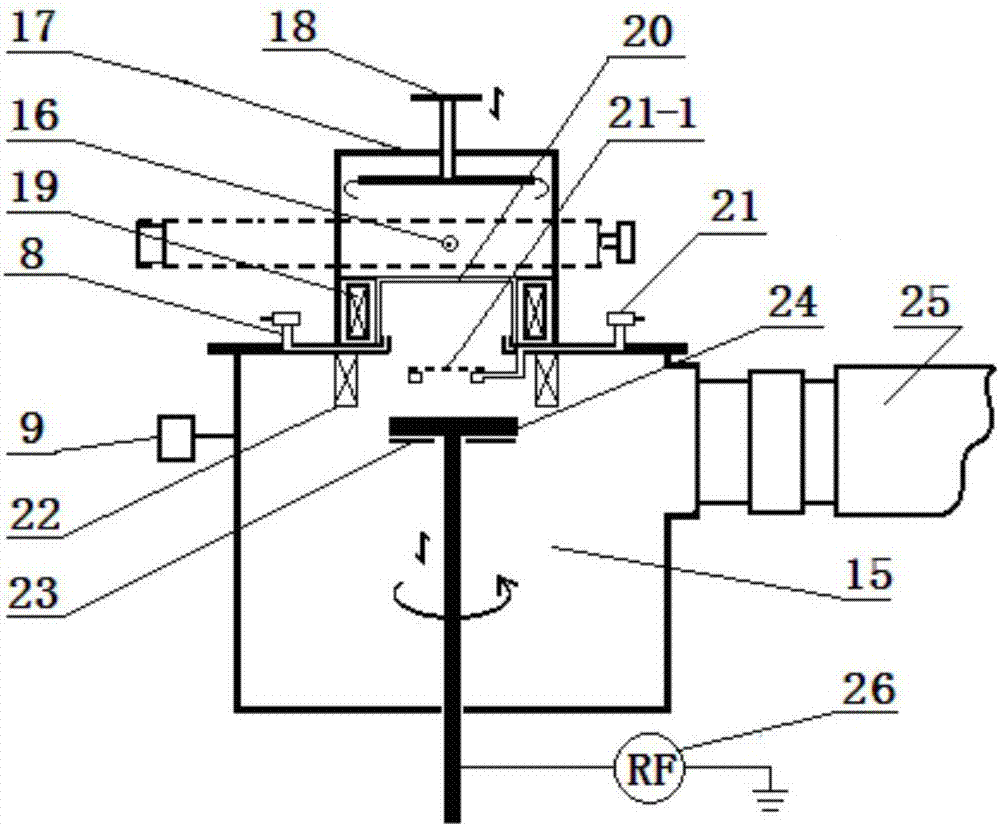

[0043] One uses magnetron sputtering equipment and ECR-PEMOCVD equipment (invention patent: ZL201210247144.8), prepared at low temperature on polyimide substrate 1, as attached figure 1 Al shown 0.10 Ga 0.40 In 0.50 The continuous process steps of N film are:

[0044] a. ECR-PEMOCVD method to prepare the first silicon oxide layer 2: Use absorbent cotton balls soaked in absolute ethanol to wipe the surface of the polyimide substrate 3 times in one direction, and then place the polyimide substrate 1 in order. Ultrasonic cleaning in water ethanol and deionized water 3 times each for 5 minutes, and then place the polyimide substrate 1 on a hot plate at 120°C for 10 minutes; the dried polyimide substrate 1 Put it into the glove box of the ECR-PEMOCVD equipment, and then transfer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com