Oxide-substrate-assisted method for quickly preparing large-size single-crystal graphene

A single crystal graphene, substrate-assisted technology, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve the problems of long processing time, complicated procedures, increased nucleation difficulty, etc., and shorten the growth cycle , increase the growth rate, good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

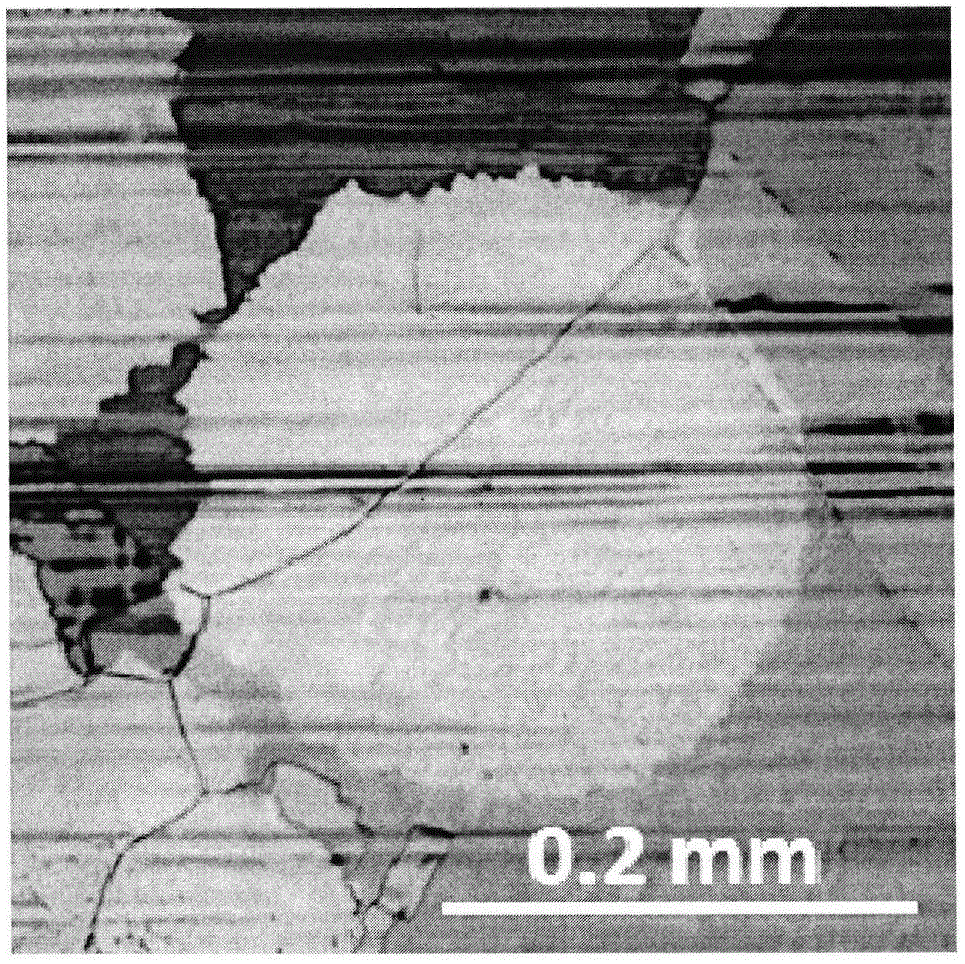

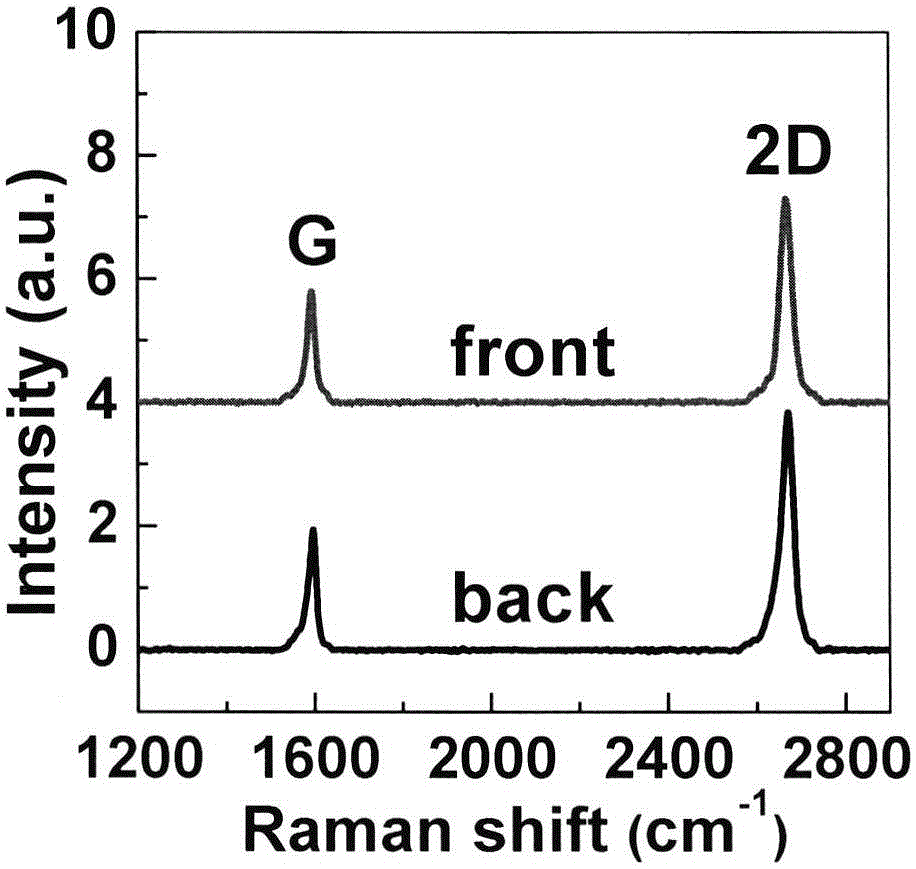

[0039] Embodiment 1: A method for rapid preparation of large-size single-crystal graphene assisted by an oxide substrate

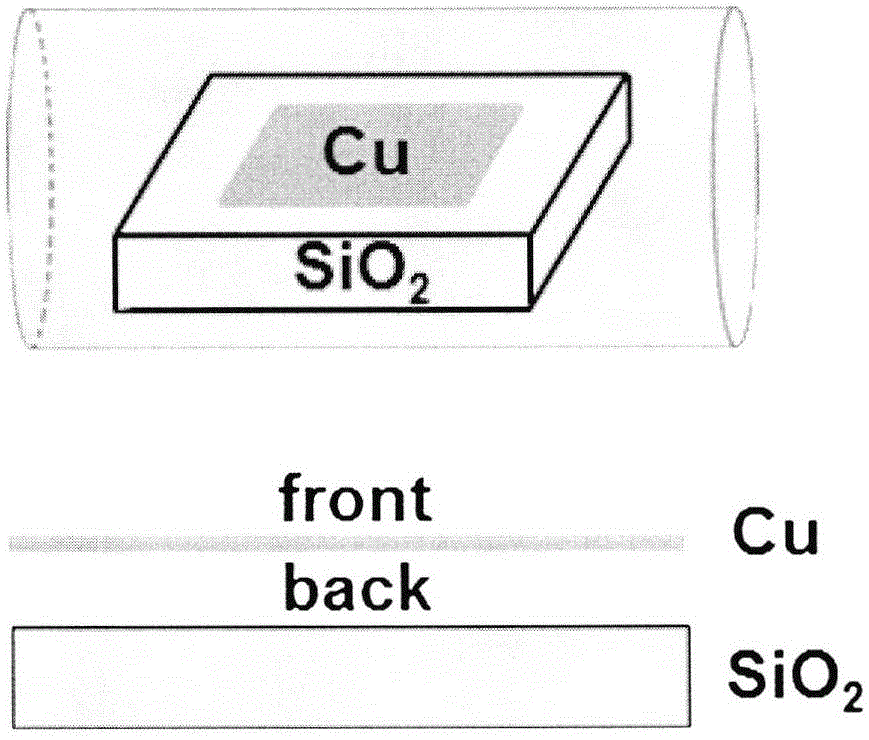

[0040] This embodiment is in figure 1 In the setup shown, a metal foil is placed on top of an oxide substrate, and the metal foil is followed by the following steps:

[0041] 1. Place the metal foil without any surface treatment on the oxide substrate, put it into the chemical vapor deposition equipment, feed Ar, the flow rate is more than 300 sccm, and the working pressure is normal pressure (that is, one atmospheric pressure or about 1× 10 5 Pa), and then start to heat up, and the heating process lasts for 50 to 70 minutes;

[0042] 2. When the temperature rises to 900~1100℃, H 2 Gas, H 2 The flow rate is 2-50 sccm, the Ar flow rate remains unchanged, and the annealing process is carried out, and the annealing duration is 30-100 min;

[0043] 3. After the annealing is over, start to introduce CH 4 gas, CH 4 The flow rate is 0.5~5sccm, adjust the H...

Embodiment approach 2

[0108] Embodiment 2: Influence of methane flow rate and growth time in an oxide substrate-assisted rapid preparation method of large-size single-crystal graphene

[0109] Experiment 1: A low-cost and fast method for preparing large-scale single-crystal graphene in this experiment is carried out according to the following steps:

[0110] 1. Place the metal copper foil without any surface treatment on Al 2 o 3 On the substrate, put it into the chemical vapor deposition equipment, feed Ar, the flow rate is 500 sccm, and the working pressure is 1×10 5 Pa, then start to heat up, and the heating process lasts for 60 minutes;

[0111] 2. When the temperature rises to 1000°C, H 2 Gas, H 2 The flow rate is 2sccm, the Ar flow rate is kept constant, and the annealing process is carried out, and the annealing duration is 40min;

[0112] 3. After the annealing is over, start to introduce CH 4 gas, CH 4 The flow rate is 0.5sccm, H 2 and Ar flow remain unchanged, the working pressure...

Embodiment approach 3

[0122] Embodiment 3: Influence of hydrogen gas flow in an oxide substrate-assisted rapid preparation of large-size single-crystal graphene

[0123] A kind of oxide substrate assisted rapid preparation method of large-scale single-crystal graphene of this experiment is to carry out as follows:

[0124] 1. Place the metal copper foil without any surface treatment on Al 2 o 3 On the substrate, put it into the chemical vapor deposition equipment, feed Ar, the flow rate is 500 sccm, and the working pressure is 1×10 5 Pa, then start to heat up, and the heating process lasts for 60 minutes;

[0125] 2. When the temperature rises to 1000°C, H 2 Gas, H 2 The flow rate is 20sccm, the Ar flow rate remains constant, and the annealing process is carried out, and the annealing duration is 40min;

[0126] 3. After the annealing is over, start to introduce CH 4 gas, CH 4 The flow rate is 5sccm, H 2 and Ar flow remain unchanged, the working pressure is 1×10 5 Pa, the growth time is 2m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com