A method and device for rapidly and continuously preparing ultra-large single crystal thin films

A technology of ultra-large single crystal and single crystal thin film, which is applied in the field of rapid and continuous preparation of ultra-large single crystal thin film, which can solve the problems of reduced film quality and mechanical properties, high production cost, complex process, etc., and achieves short preparation cycle, reduced preparation cost, The effect of simplifying the growth process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

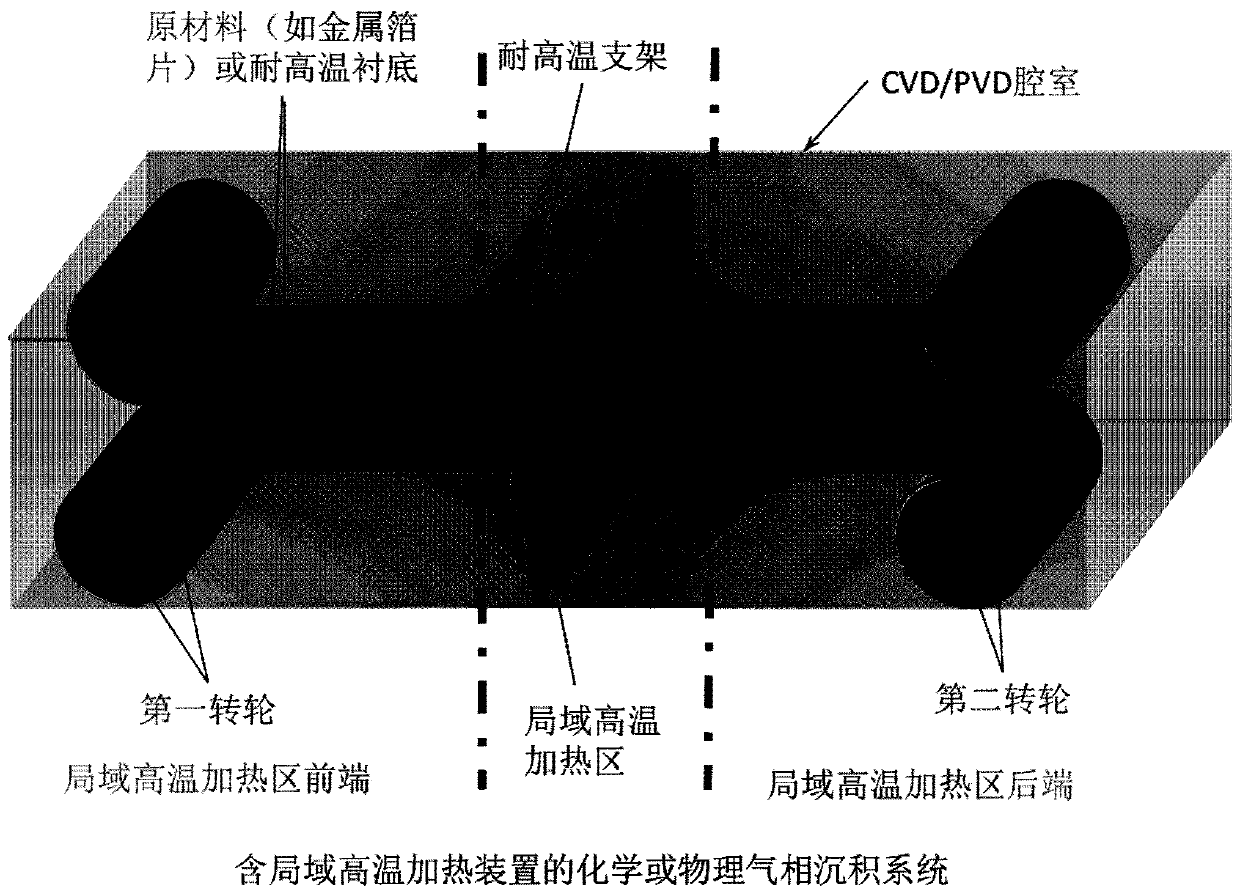

[0048] Embodiment 1: A method for rapid and continuous preparation of ultra-large single crystal thin films

[0049] This embodiment is in figure 1 In the device shown, the raw material (such as metal foil) or the required high-temperature-resistant substrate is placed in a high-temperature-resistant isolation bracket, figure 1 Among them are two raw materials (such as metal foil) or the required high-temperature resistant substrate and two layers of high-temperature-resistant isolation brackets, wherein the materials of high-temperature-resistant isolation brackets are graphite, boron nitride, ceramics, metal molybdenum, metal tantalum, Quartz, fused silica, Al 2 o 3 , ZrO, or MgO, and proceed as follows:

[0050] (1), put the raw material (such as metal foil) or the required high-temperature-resistant substrate in a high-temperature-resistant isolation bracket, place it on a local high-temperature heating body, put it into a chemical or physical vapor deposition equipment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com