A preparation method of sub-10 nanometer stable graphene quantum dots

A graphene quantum dot and nano technology, applied in the direction of nano technology, metal material coating process, coating, etc., can solve the problem that the scale of quantum graphene is far apart, and achieve shortened growth cycle, stable performance and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

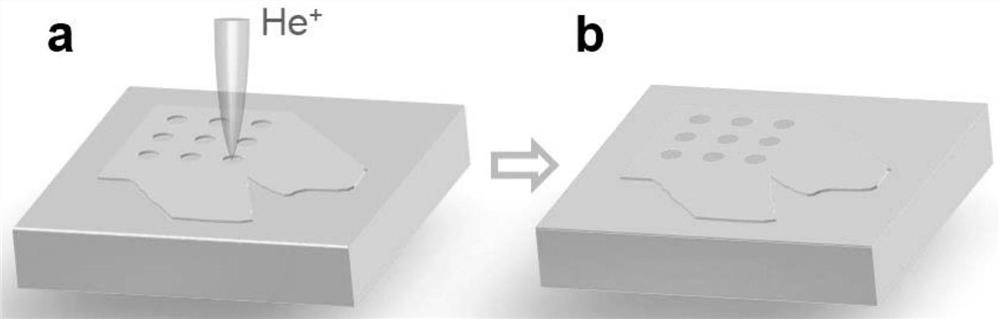

[0032] Embodiment 1: A method for growing graphene quantum dots in boron nitride nanopores

[0033] This embodiment is in figure 1 In the device shown, the bulk boron nitride is torn off by hand with adhesive tape and a few layers of boron nitride are placed on the metal foil, and the steps are as follows:

[0034] 1. Tear off the bulk boron nitride with tape and peel off a few layers of boron nitride onto the metal foil, and put it into a chemical vapor deposition equipment for annealing (this step is mainly to remove the tape residue). into Ar / H 2 =500 / 10sccm, the working pressure is normal pressure (that is, one atmospheric pressure or about 1×10 5 Pa), then start to heat up, the heating process lasts for 50-70min, stop heating after reaching 1000°C, and cool down to room temperature naturally;

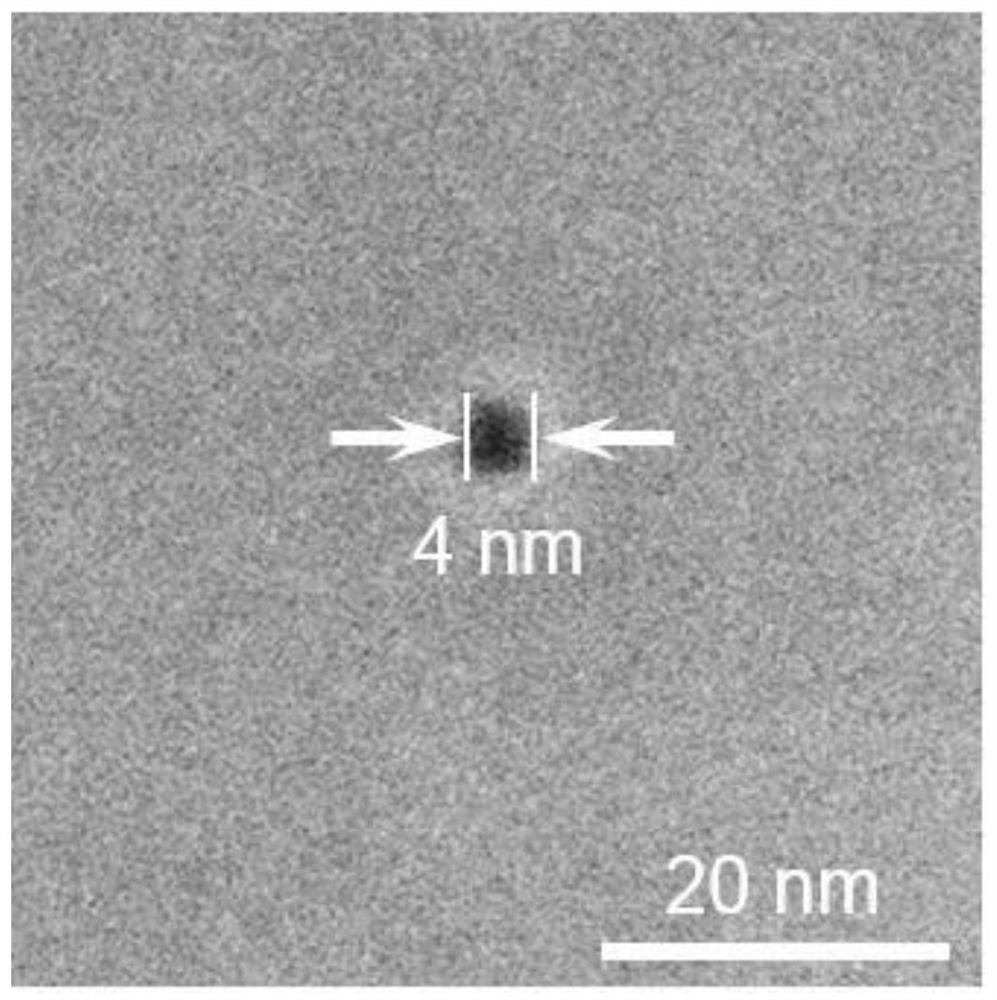

[0035] 2. Take out the sample and put it into the cavity of the helium ion microscope, and use the helium ion beam to etch nano-holes of different sizes on the boron nitride, an...

Embodiment approach 2

[0051] Embodiment 2: A method for growing graphene quantum dots in boron nitride nanopores by chemical vapor deposition

[0052] This embodiment is in figure 1 In the setup shown, boron nitride was grown on top of a metal foil by chemical vapor deposition and proceeded as follows:

[0053] 1. Put the metal foil in the chemical vapor deposition equipment. into Ar / H 2 =500 / 5sccm, the working pressure is normal pressure (that is, one atmospheric pressure or about 1×10 5 Pa), and then start to heat up. The heating process lasts for 50-70 minutes. After reaching 1000°C, heat the BH 3 -NH 3 Pass the boron source and nitrogen source, after one hour, stop heating BH 3 -NH 3 , naturally cooled to room temperature;

[0054] 2. Take out the sample and put it into the cavity of the helium ion microscope, and use the helium ion beam to etch nano-holes of different sizes on the boron nitride, and the dose and etching time can be selected according to the state of the instrument;

[...

Embodiment approach 3

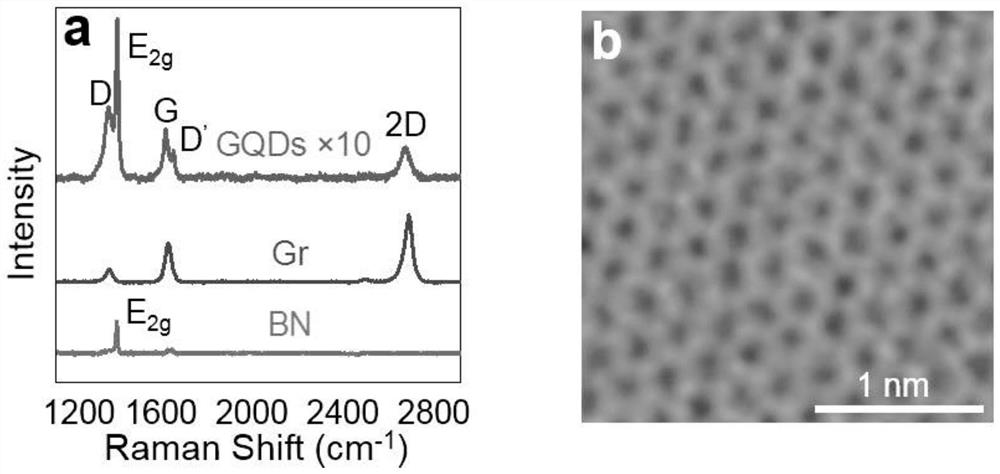

[0069] Embodiment 3: Stability analysis of a sub-10nm graphene quantum dot

[0070] Test three: the verification of the stability of a sub-10nm stable graphene quantum dot in this test is carried out according to the following steps:

[0071] 1. Purchase commercial graphene quantum dots as a comparison;

[0072] 2. Test the changes of the Raman spectrum and fluorescence spectrum of the purchased graphene quantum dots baked at different temperatures for different times;

[0073] 3. Test the Raman spectrum of the graphene quantum dots grown in this patent over time;

[0074] 4. The comparison results show that the purchased commercial graphene quantum dots are baked at 100°C for 5 minutes, the Raman spectrum disappears, and the fluorescence spectrum attenuates seriously. The fluorescence basically disappeared after 10 minutes. However, the graphene quantum dots applied for in this patent are baked under the same conditions for 100 days, and the graphene Raman spectrum does no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com