A method for rapid and continuous preparation of large domain graphene films

A graphene film and crystal domain technology, which is applied in the field of rapid and continuous preparation of large crystal domain graphene films, can solve the problems of slow growth of graphene films, energy consumption, gas consumption, and cost increase, and achieve good application prospects and reduce Production cost and effect of fewer defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

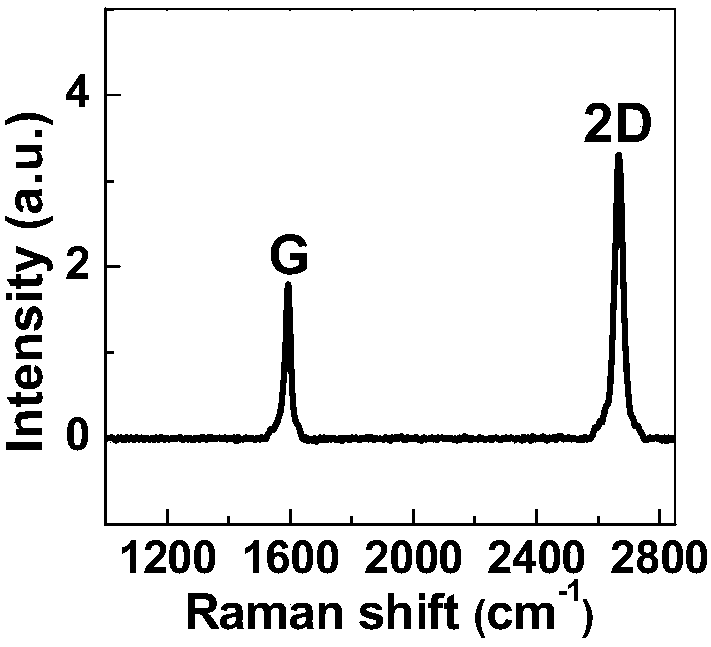

[0043] Embodiment 1: A method for rapid and continuous preparation of large domain graphene films

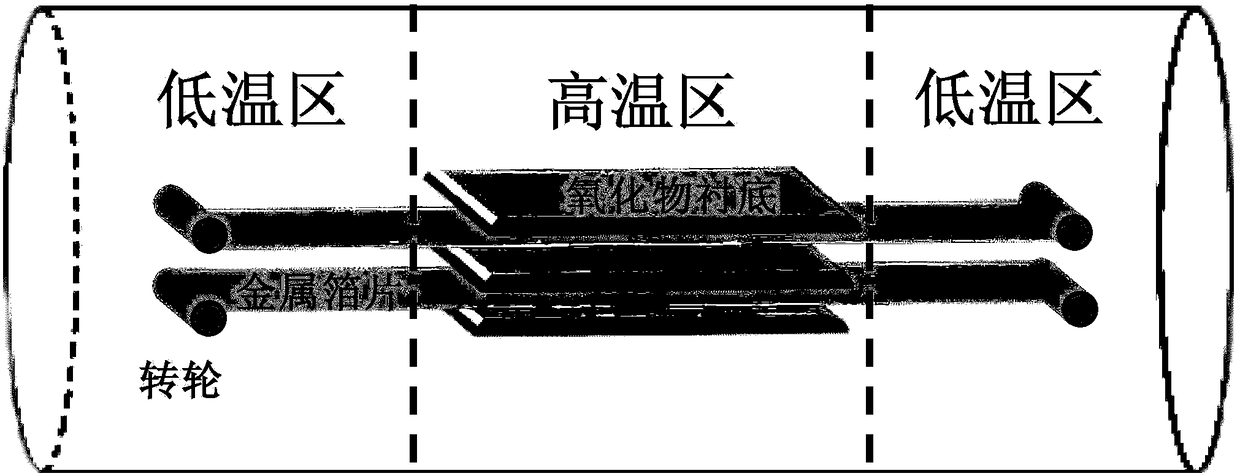

[0044] This embodiment is in figure 1 In the setup shown, a metal foil is placed in an oxide substrate sandwich, figure 1 Among them are two metal foils and three oxide substrates, and proceed as follows:

[0045] (1) Place the metal foil without any surface treatment in the interlayer of the oxide substrate, put it into the chemical vapor deposition equipment, feed Ar, the flow rate is more than 300 sccm, and then start to heat up, and the heating process lasts for 50~ 70min;

[0046] (2) When the temperature rises to 900~1100℃, H 2 Gas, H 2 The flow rate is 0.2-50sccm, the Ar flow rate remains unchanged, and CH is started to be introduced at the same time 4 gas, CH 4 The flow rate is 0.5~50sccm;

[0047] (3) Simultaneously control the driving device to slowly move the runners at both ends, so that multiple metal foils pass slowly through the oxide plate interlayer at th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| translucency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com