A method for preparing a large-scale two-dimensional single crystal stack with interlayer corners

A large-scale, single-crystal technology, applied in the field of materials, can solve the problems of inability to obtain a large-area strong interaction clean contact surface, complex operation, harsh conditions, etc., and achieve the effects of short preparation cycle, high sample quality and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

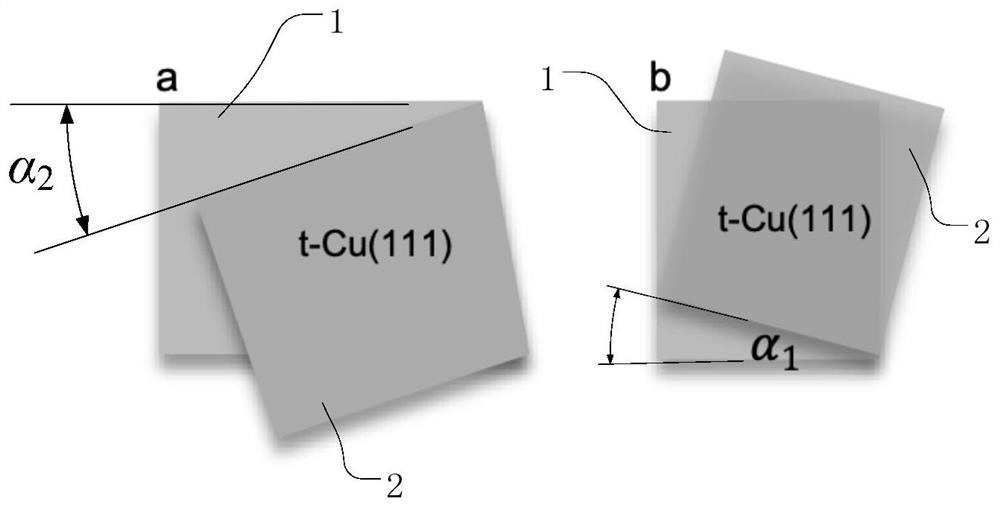

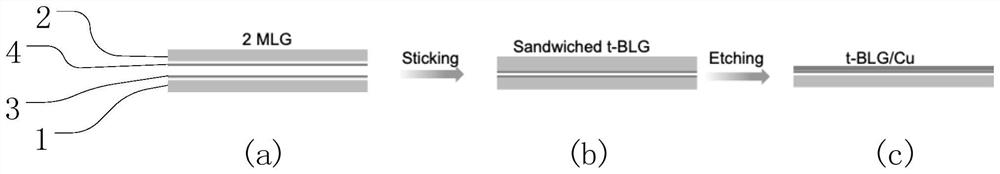

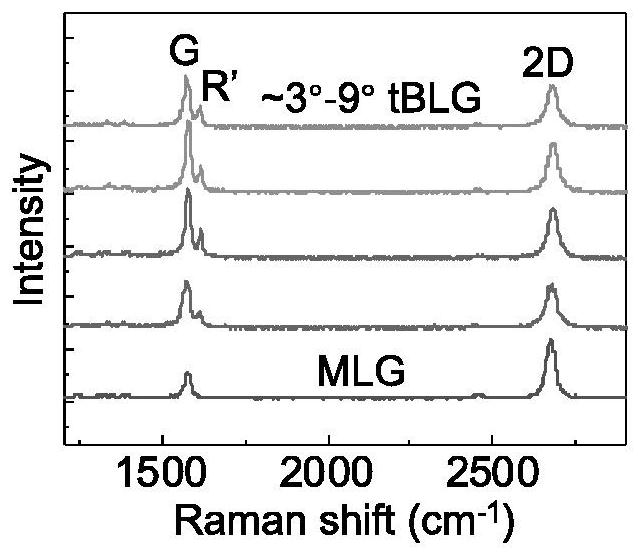

[0045] Wherein, the interlayer rotation angle α can be designed as required, for example, the interlayer rotation angle α can be 0°<α<90°.

[0057] 2. The corner two-dimensional single crystal stack grown in this embodiment is large in size and high in quality, and has good application prospects.

Embodiment approach 1

Embodiment approach 2

[0075] Embodiment 2: a method for preparing large-size specific corner single crystal boron nitride.

[0082] The double-layer monocrystalline boron nitride prepared in this experiment is large in size, high in quality and controllable in turning angle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com