Method for strengthening and repairing tubular pile head

A pipe pile head and pile head technology, which is applied in the field of reinforcement and repair of pipe pile heads, can solve the problems of secondary damage to the pile head and low repair success rate, so as to reduce the probability of damage again, avoid stress concentration, The effect of high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A method for reinforcing and repairing pipe pile heads, characterized in that:

[0019] Step 1) Remove the damaged and loose concrete, expose the main reinforcement 3-4cm and straighten it to make it vertical to the ground, and saw off the concrete at the damaged pile head, and then saw off the concrete; then wash away the floating ash and the soil on the surface of the concrete, After drying, add a pile cap of the same specification on the pile head, and connect the exposed main reinforcement with the pile cap.

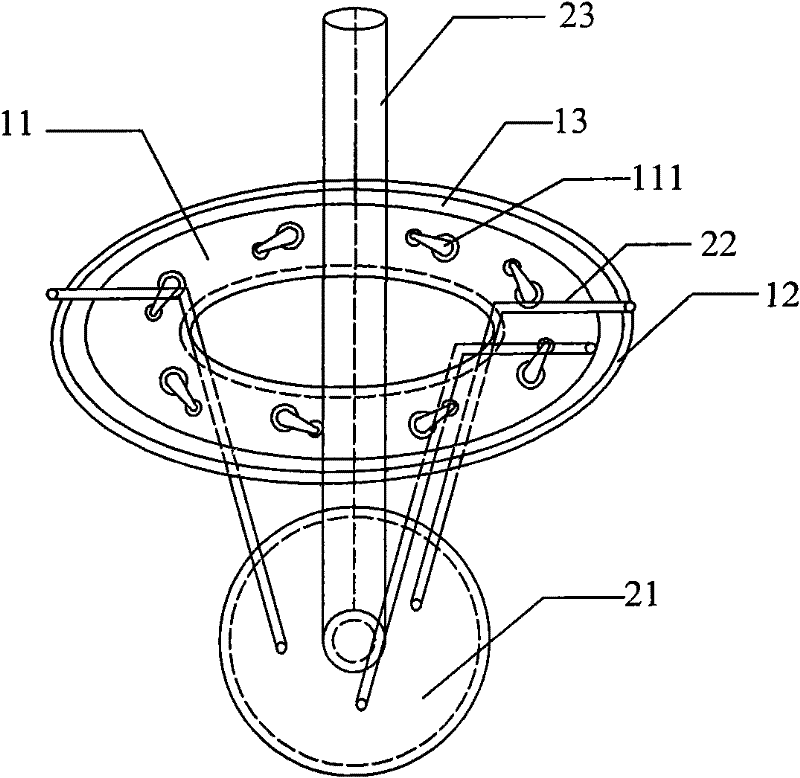

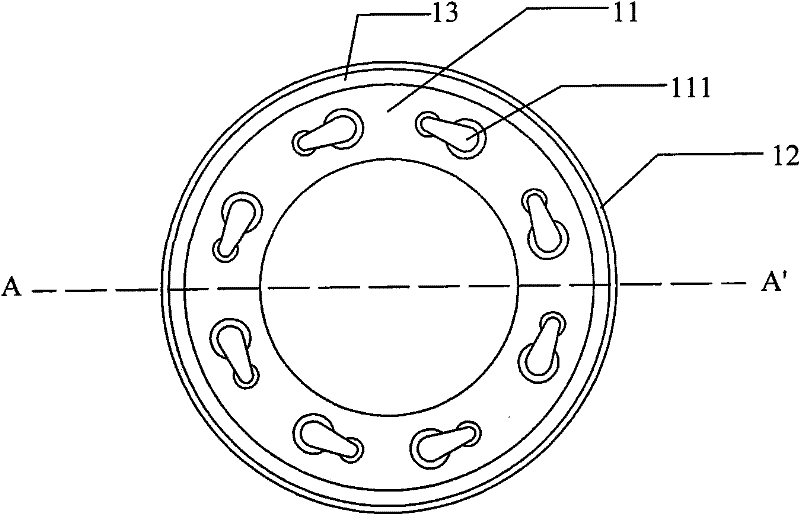

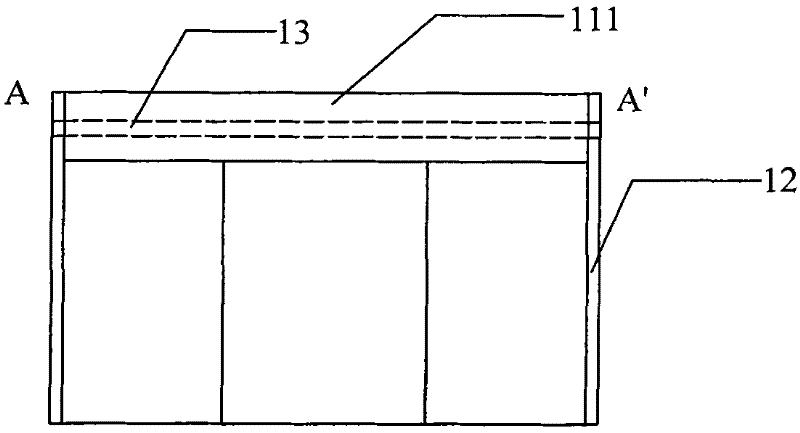

[0020] The pile cap includes: a circular end plate 11, and a cylindrical steel ferrule 12 is set on the circular end plate 11. The surface of the circular end plate 11 is coplanar with the end surface of the cylindrical steel ferrule 12 and the circular end plate 11 Connected with the cylindrical steel ferrule 12, an end plate screw hole 111 is provided on the circular end plate 11, and a ring rib 13 is also provided between the circular end plate 11 and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com