Embedded elastic rubber bearing device and construction method of applying bearing device to connection between prefabricated concrete bridge pier and pile cap

A prefabricated concrete and elastic rubber technology, applied in the erection/assembly of bridges, bridges, bridge parts, etc., can solve the problems of reduced ductility coefficient of bridge piers, concrete cracking, low structural energy dissipation capacity, etc., to achieve good post-earthquake use function, increase The effect of ductility and good self-resetting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

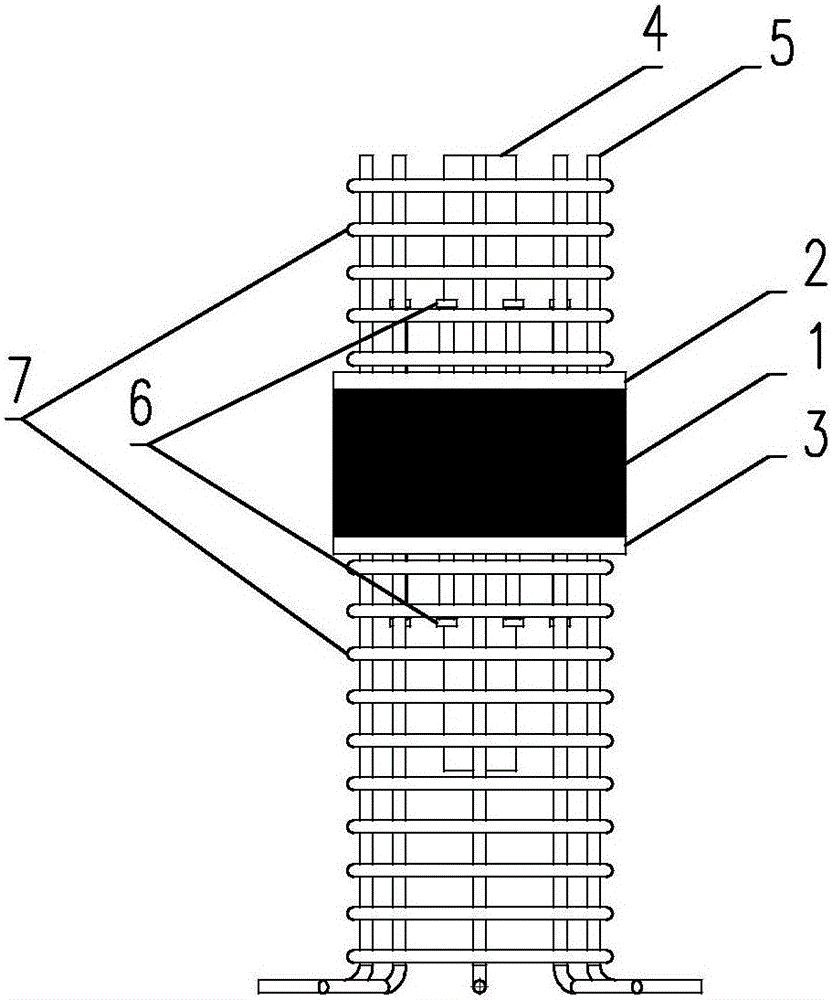

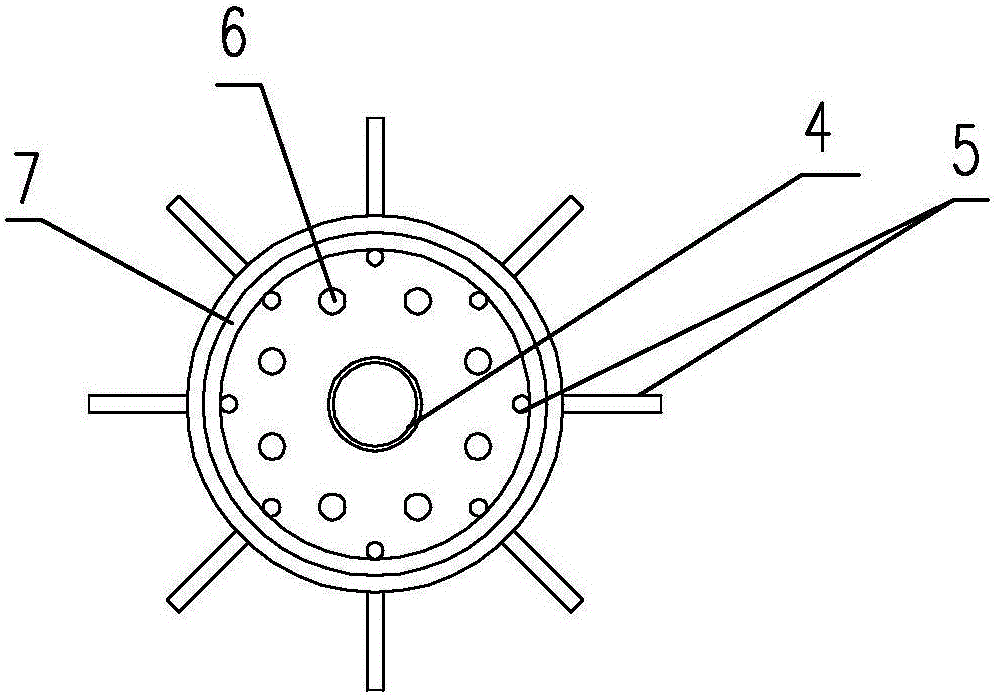

[0039] An implantable elastic rubber bearing device:

[0040] Such as Figure 2-Figure 4 As shown, the implanted elastic rubber bearing device includes an elastic rubber bearing 1, an upper reinforcing steel plate 2 and a lower reinforcing steel plate 3, and a steel pipe hole I101 for post-tensioning prestressed beams to pass through is opened in the center of the elastic rubber bearing 1. The energy-dissipating steel hole I102 for inserting the energy-dissipating steel bar 5 is opened around the elastic rubber bearing 1; the upper reinforcing steel plate 2 and the lower reinforcing steel plate 3 are respectively opened with post-tensioning prestressed steel beam hole II201 and steel tube for beam penetration Hole Ⅲ301, energy-dissipating steel bar hole Ⅱ202 and energy-dissipating steel bar hole Ⅲ302 for interspersing energy-dissipating steel bar 5 are opened on the periphery, steel pipe hole Ⅱ201 for beam penetration and steel tube hole Ⅲ30 for beam penetration on upper reinf...

Embodiment 2

[0043] A construction method for connecting prefabricated concrete bridge pier columns and caps:

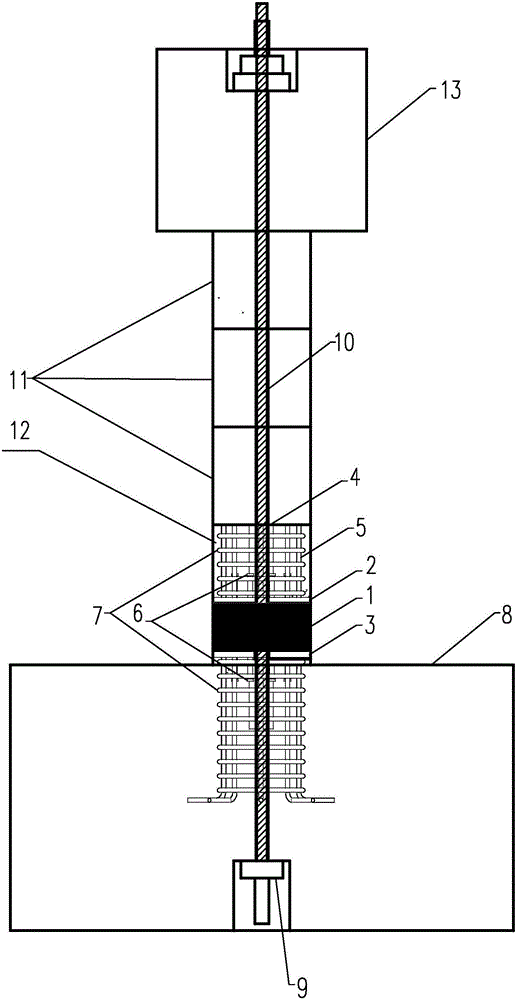

[0044] It is a construction method that uses the implanted elastic rubber bearing device described in Example 1 to realize the connection between the cast-in-place reinforced concrete cap and the first section of the bridge pier, and the implanted elastic rubber bearing device is pre-embedded in the cast-in-place reinforced concrete At the connection between the cap and the pier column of the first section, the cast-in-place reinforced concrete cap, the pier column of the first section, the prefabricated pier section, and the cover beam are formed by a prestressed anchorage system and a prestressed bundle. The post-tensioned unbonded prestressed system is connected; the connection construction includes the following four steps:

[0045] A. Making implantable elastic rubber bearing device:

[0046] A1. Hole opening: Hole Ⅰ101 of the steel pipe for post-tensioning prestressed beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com