Device for measuring negative skin friction of pile soil

A measuring device and technology of negative frictional resistance, which is applied in the field of devices for measuring the performance of soil with piles, can solve the problems of limited container space, low soil load value, limited height and sand density, etc., and achieve sufficient placement space , The settlement of the soil is obvious, and the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

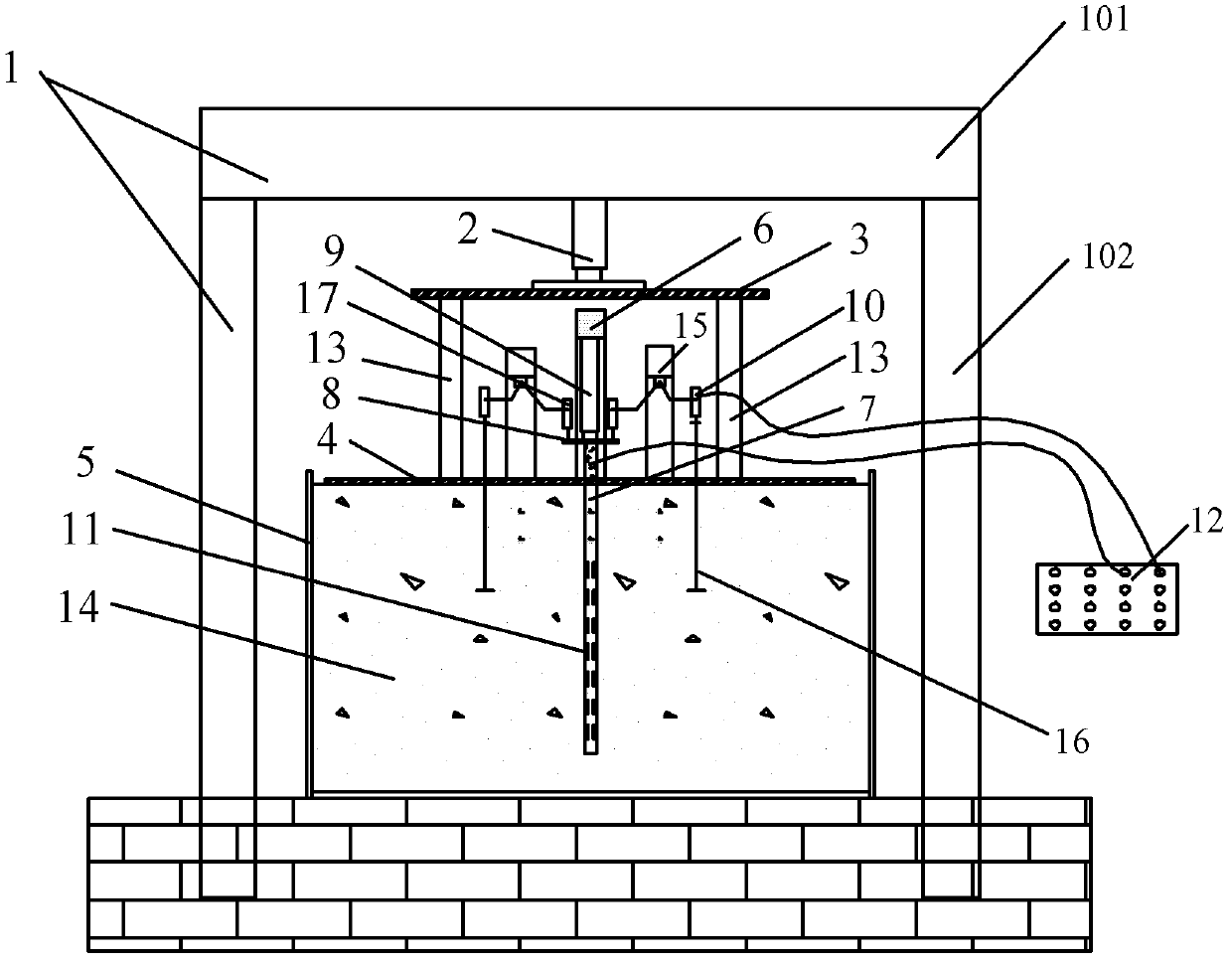

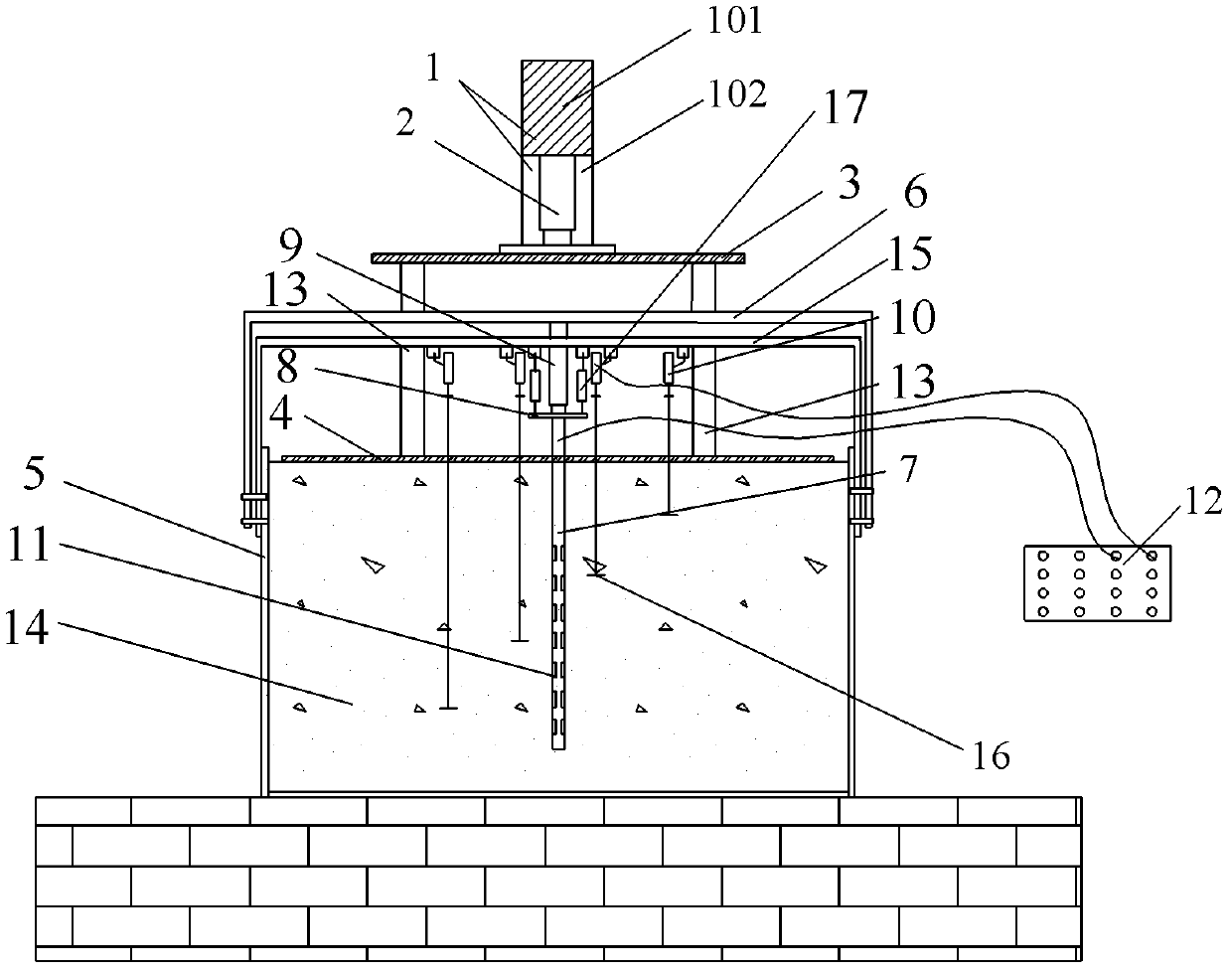

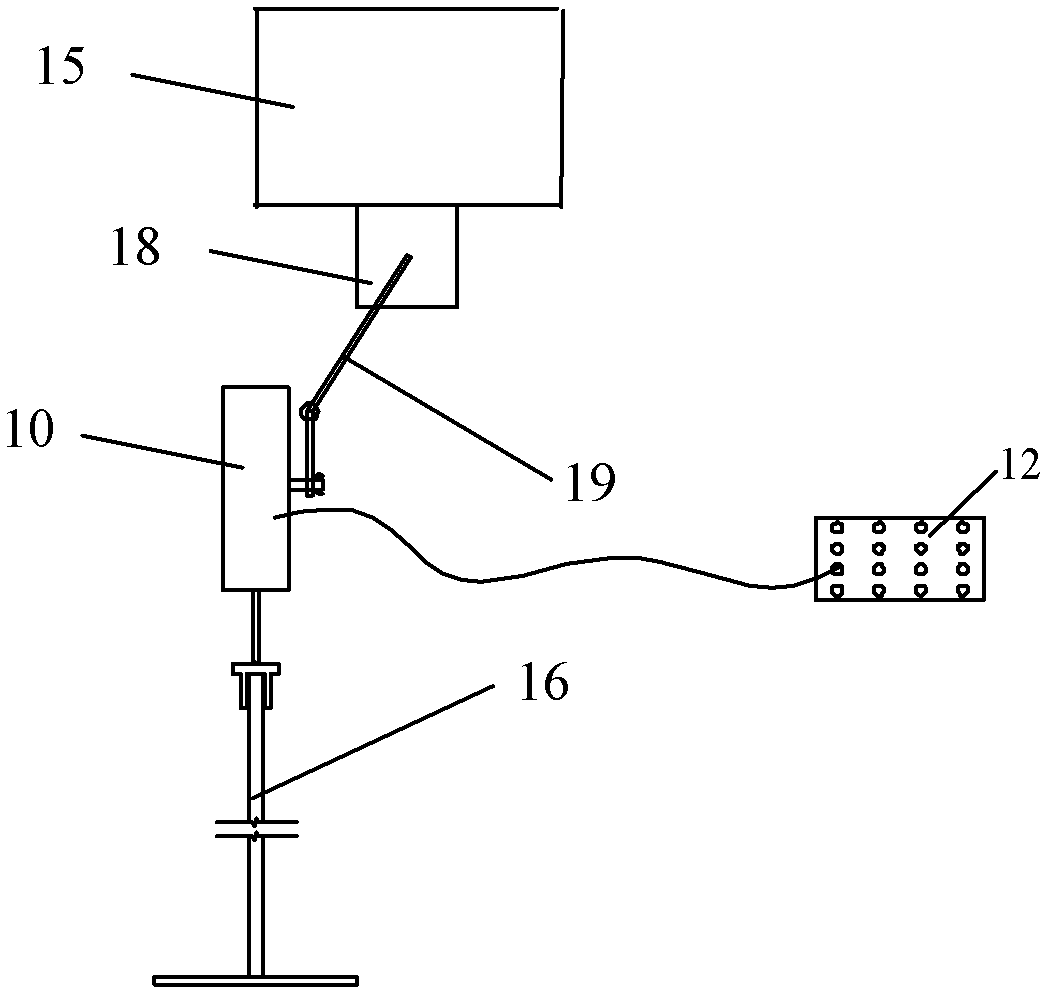

[0023] Such as Figure 1 to Figure 4 As shown, a measuring device for pile-soil negative friction resistance of the present invention includes a first reaction force device 1 containing a first top beam 101, an upper jack 2, an upper load plate 3, a lower load plate 4, and a soil body 14 of the test box 5, the second counter force device 6 containing the second top beam, the model pile 7, the bearing plate 8, the lower jack 9, the first displacement sensor 10, the strain gauge 11, the strain acquisition instrument 12, the balance beam 15. Settlement mark 16 and second displacement sensor 17. The first reaction force device 1 , the second reaction force device 6 and the strain collector 12 are located outside the test box 5 . The lower load plate 4 is located on the upper surface of the soil body 14 in the test box 5 . The lower load plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com