Process method for rectifying deviation of open caisson by jacking balance of jack

A process method and jack technology, applied in caissons, infrastructure engineering, construction, etc., can solve problems such as uneven deviation, achieve the effect of saving construction costs and solving uneven settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

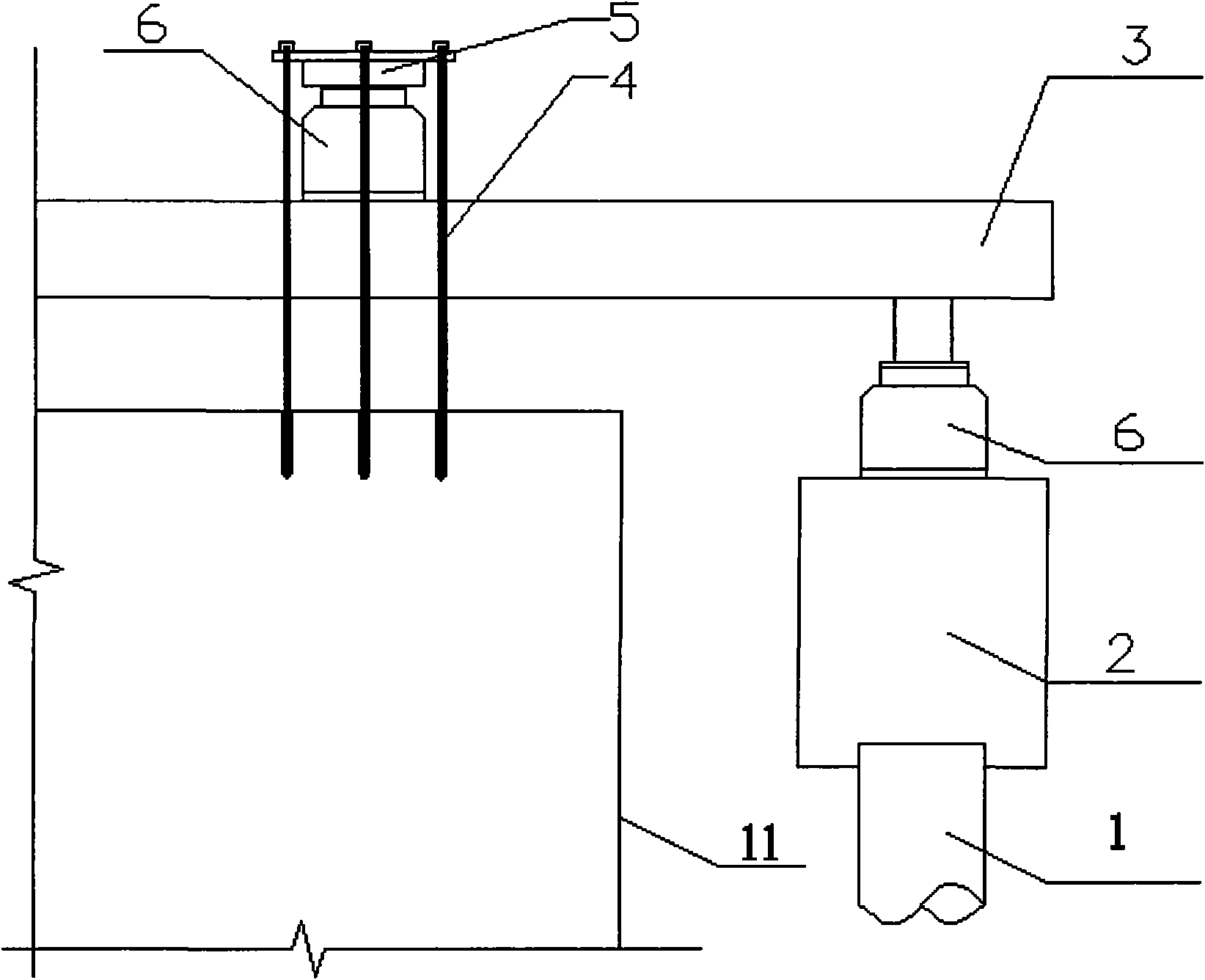

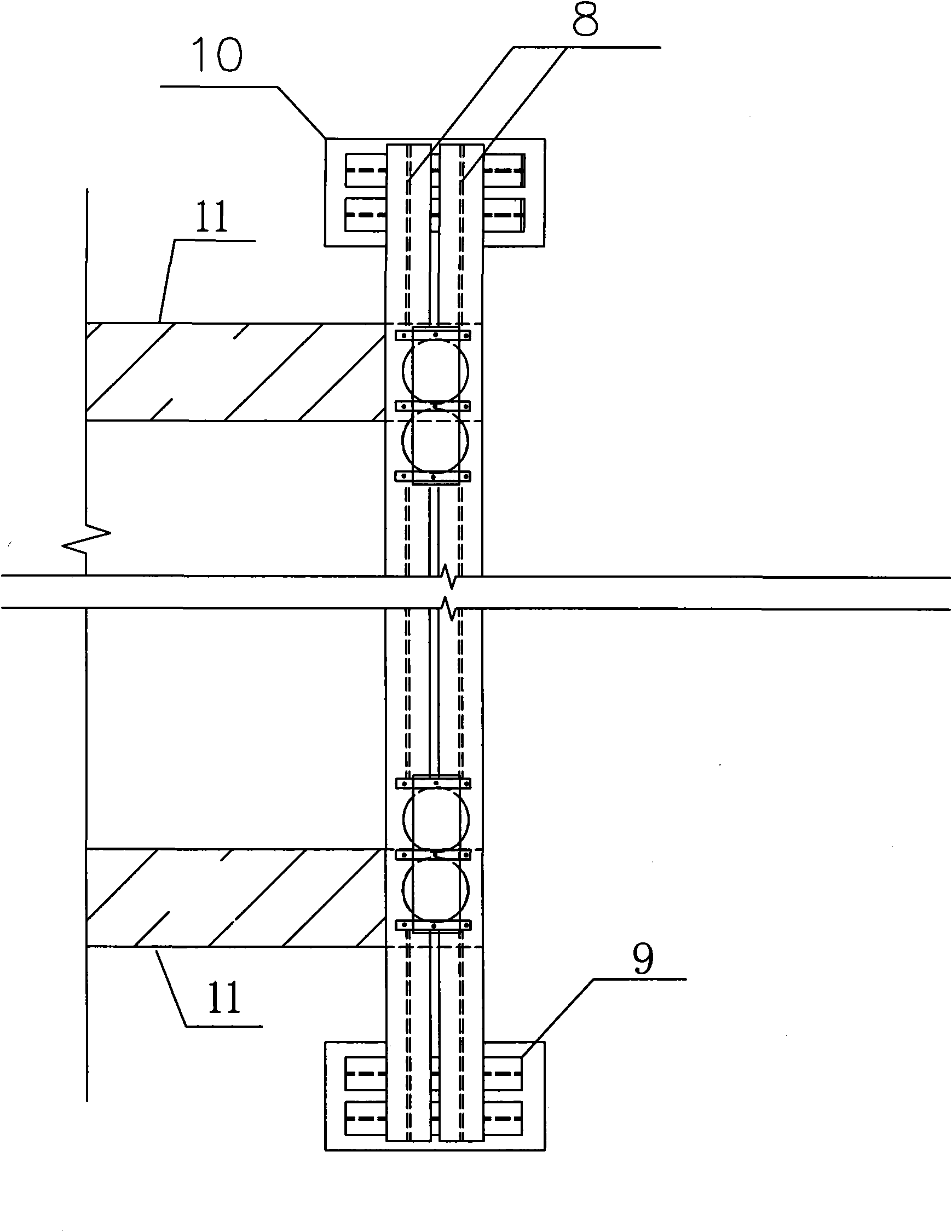

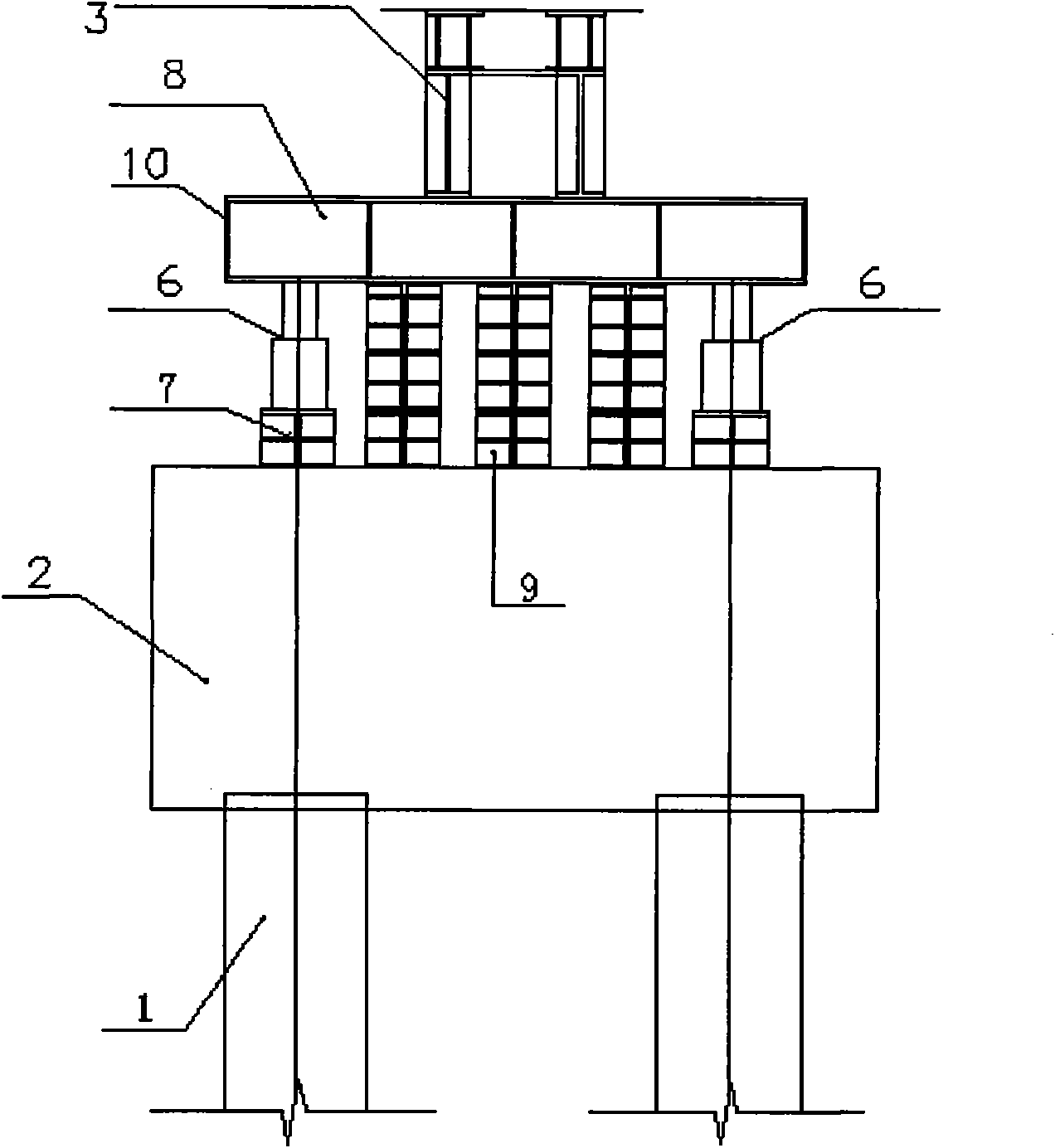

[0027] see Figure 1-Figure 4 As shown, the embodiment process steps of carrying out caisson deviation correction by jack lifting balance of the present invention are:

[0028] The first step, setting up the deviation correction device

[0029] (1) A total of eight Φ500mm prestressed pipe piles 1 are drilled at the four corners outside the concrete box 11 as stress points, and two prestressed pipe piles 1 are set at each corner as a group, and a 5t diesel hammer pile machine is used For prestressed pipe piles and hammer piles, the penetration of each of the last three hammers is 30mm, and the safe bearing capacity of a single pile is 2000KN.

[0030] (2) A pile cap 2 is arranged above the two prestressed pipe piles 1 at each corner. The size of the pile cap 2 is 2500×1000×1200mm, and it is poured with C40 concrete.

[0031] (3), install the steel truss 3. The steel truss 3 is formed by welding the 45b I-beam 8 and the connecting piece, and the steel truss 3 is supported on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com