Combined-type composite foundation with controllable rigidity piles, drainage materials and reinforced cushion

A technology of reinforced cushion and composite foundation, which is applied in basic structure engineering, soil protection, construction, etc., to achieve the effects of reducing differential settlement, increasing stability, and improving transverse bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

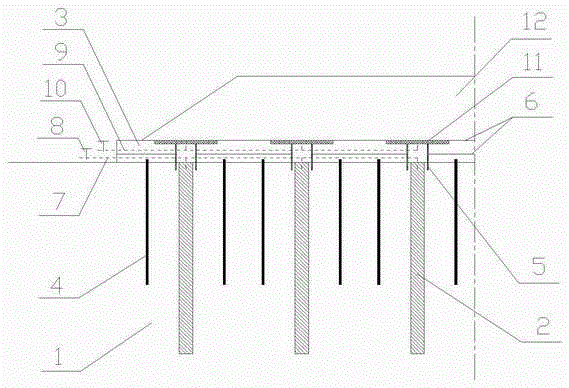

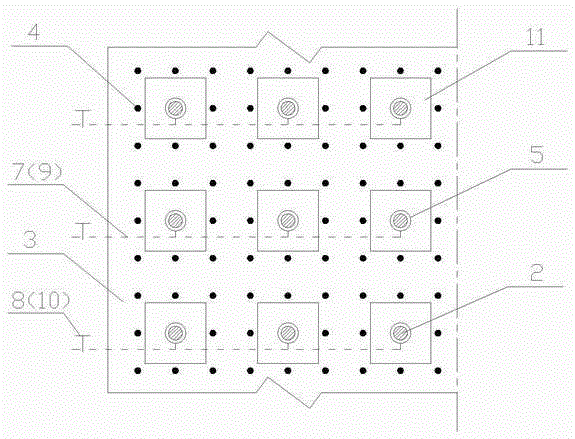

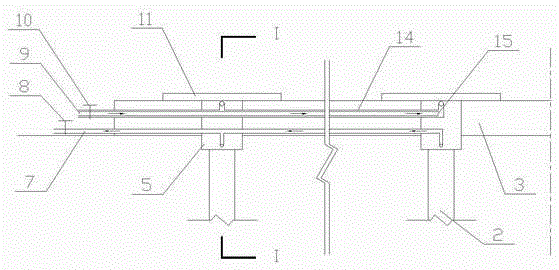

[0033] The construction steps of the composite foundation with controllable rigid pile + drainage body + reinforced cushion are as follows:

[0034] (1) in figure 1 In the process, the site is first leveled, and the rigid pile 2 is constructed in the soft soil foundation 1;

[0035] (2) Lay a layer of sand cushion 3 not less than 300mm on the surface, and then construct vertical drainage body 4. The top of vertical drainage body 4 should enter the sand cushion 3 to ensure that the drainage systems are connected to each other;

[0036] (3) Clear the sand cushion layer 3 above the top surface of the rigid pile 2, bury the grouting cylinder 5, and the lower end of the grouting cylinder 5 covers the pile head of the rigid pile 2, such as figure 1 shown;

[0037] (4) Then install the drainage pipe 7, the drainage pipe 7 is connected to each grouting cylinder 5 in the same cross section, extends horizontally beyond the range of the sand cushion layer 3, and connects to the pumping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com