Method for testing characters of micro piles in landslide control

A test method and technology of micro piles, which are applied in the test of infrastructure, construction, infrastructure engineering, etc., can solve the problem that the reliability of calculation results needs to be further discussed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1, the test method of the micropile character in landslide prevention and control.

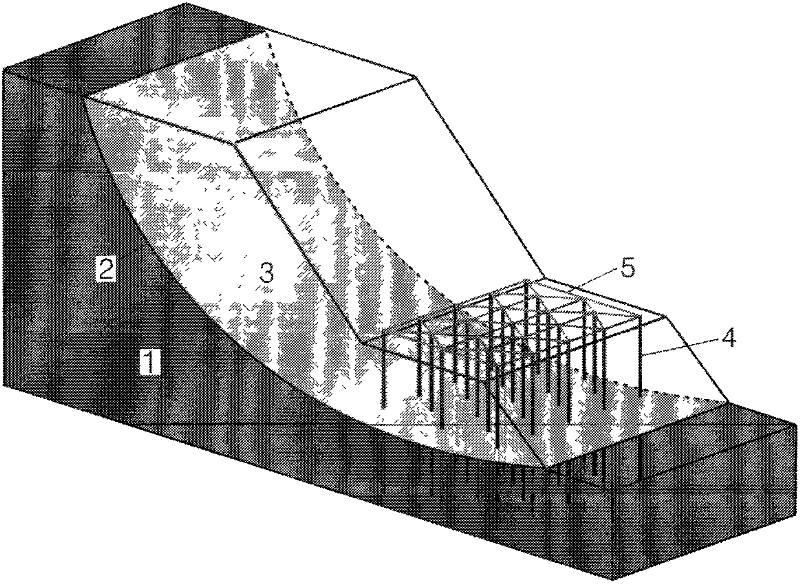

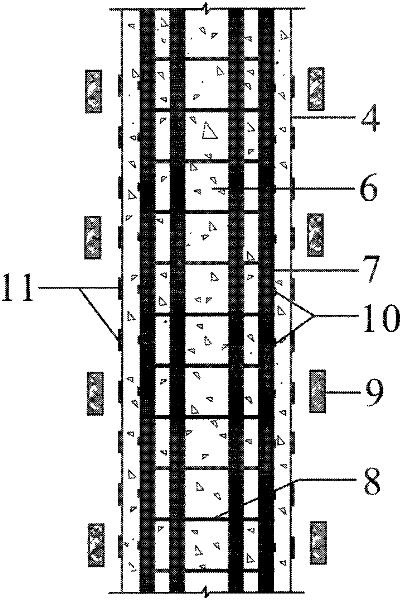

[0037] The present invention first needs to set up a large-scale physical landslide model, and the physical landslide model includes: a sliding bed, a sliding surface, a sliding body, and a plurality of micro piles and a plurality of monitoring devices arranged therein. The above-mentioned sliding bed and sliding body can be arranged mainly by layered filling with soil as the medium, and the above-mentioned micro piles can be prefabricated piles (such as reinforced concrete prefabricated piles, etc.). Secondly, loading on the slope top of the successfully set physical landslide model, and obtaining the data of each monitoring device, the slide of the landslide under loading is helpful for the study of the behavior of the micropile in the whole process from stress to failure under the action of the landslide. Finally, after the loading is stopped, section excavation can be car...

Embodiment 2

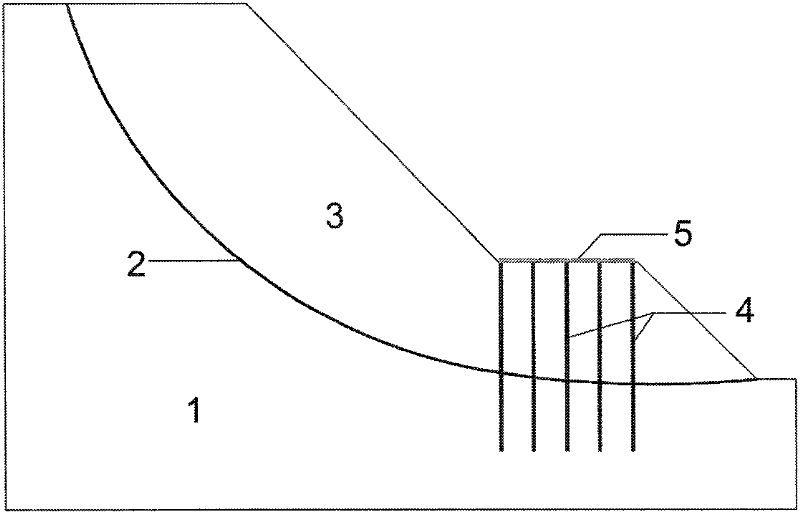

[0074] Embodiment two, the test method of the micropile character in landslide prevention and control. Attached below Figures 1 to 3 The test method will be described.

[0075] Step 1. Carry out experimental design. Specifically, according to the conditions of the test site and the similarity theory, the landslide model (including the model of the sliding bed 1 and the sliding body 3) and the micro-pile model (including the micro-pile 4, strain gauges 10 and 11, and earth pressure cell) in the test were designed. 9, the miniature pile top connection beam 5 and the model including the pile top displacement monitoring device).

[0076] In order to ensure the smooth progress of the test, when designing the landslide model, it should be ensured that the stability coefficient of the landslide model is between 1.0 and 1.1 without micro-piles, that is, the landslide model is in a basically stable state. As for too large, so as to avoid increasing the difficulty of the test. Para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com