Method for surrounding water by combination of steel cofferdam and heavy-pressure rotary-spraying pile in deep-water low-pile cap construction

A technology of high-pressure rotary grouting piles and steel cofferdams, which can be applied to sheet pile walls, foundation structure engineering, erection/assembly of bridges, etc., and can solve problems such as complex construction, difficult operation, and increased investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

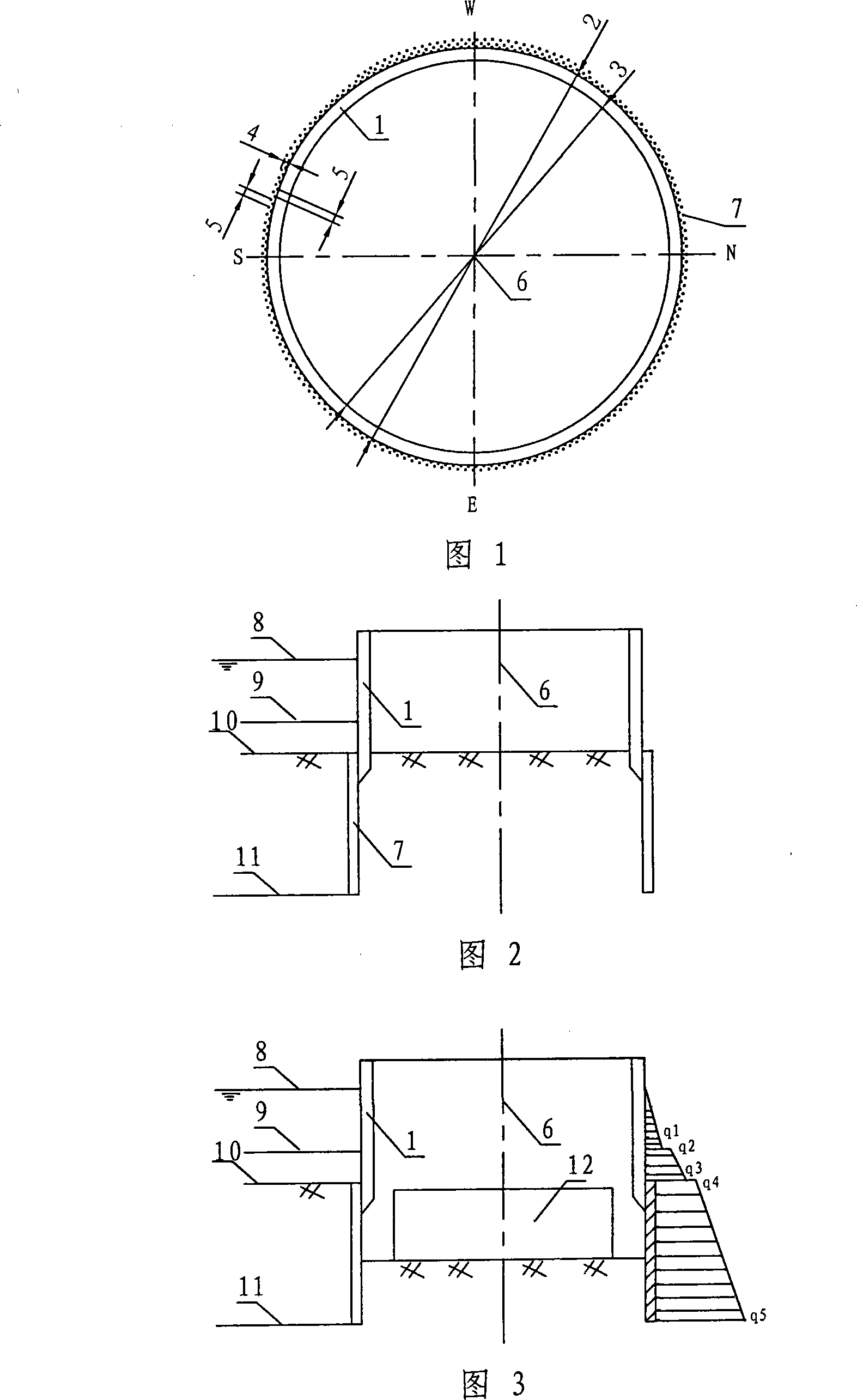

[0013] The Huaihe Highway Bridge is a super-highway bridge spanning the Huaihe River, with a total length of 1730m, two lanes and four lanes. The main span adopts a 140m prestressed reinforced concrete continuous rigid structure. The main pier is located in the Huaihe River. The foundation adopts 14φ2.0m drilled rock-socketed columns Pile, low pile cap, the cap is 4.5m thick. The maximum water depth from the top of the cap to the water surface is about 6.5m.

[0014] Basic information of the main pier:

[0015] Main pier data:

[0016] Construction water level: +13.0m

[0017] River bed elevation: +7.00~+7.5m

[0018] Elevation of the top surface of the bearing platform: +6.524m

[0019] Elevation of the bottom surface of the platform: +2.024m

[0020] The main pier is located in the water of the Huaihe River, and the exposed cohesive soil is an impermeable soil layer, and only the sand and sub-sandy soil layers are permeable layers, which form a complementary relationshi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com