Method for treating soft soil roadbed by artificial composite crust layer

A technology of soft soil subgrade and hard crust, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of large impact on the surrounding environment, unfavorable environmental protection, limited to lime soil and geogrid, etc., and achieve improvement Bearing capacity and anti-deformation performance, high bearing capacity and uneven settlement resistance, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

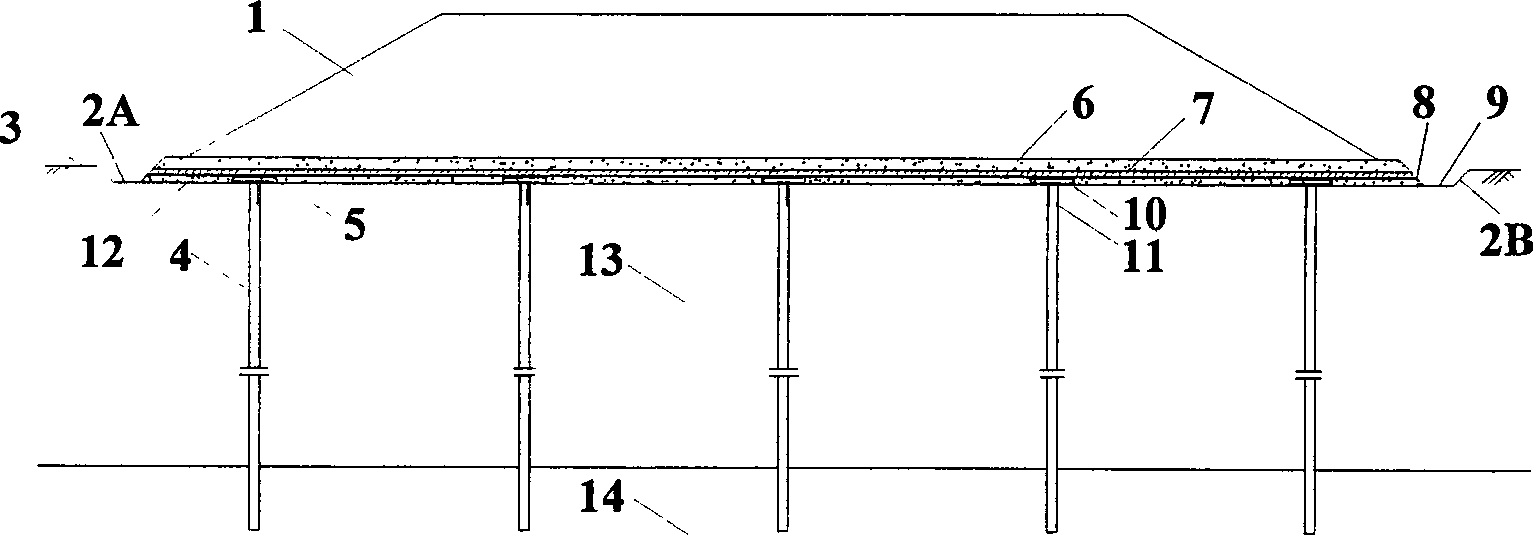

[0017] Details and working conditions of the present invention will be further described below in conjunction with the accompanying drawings.

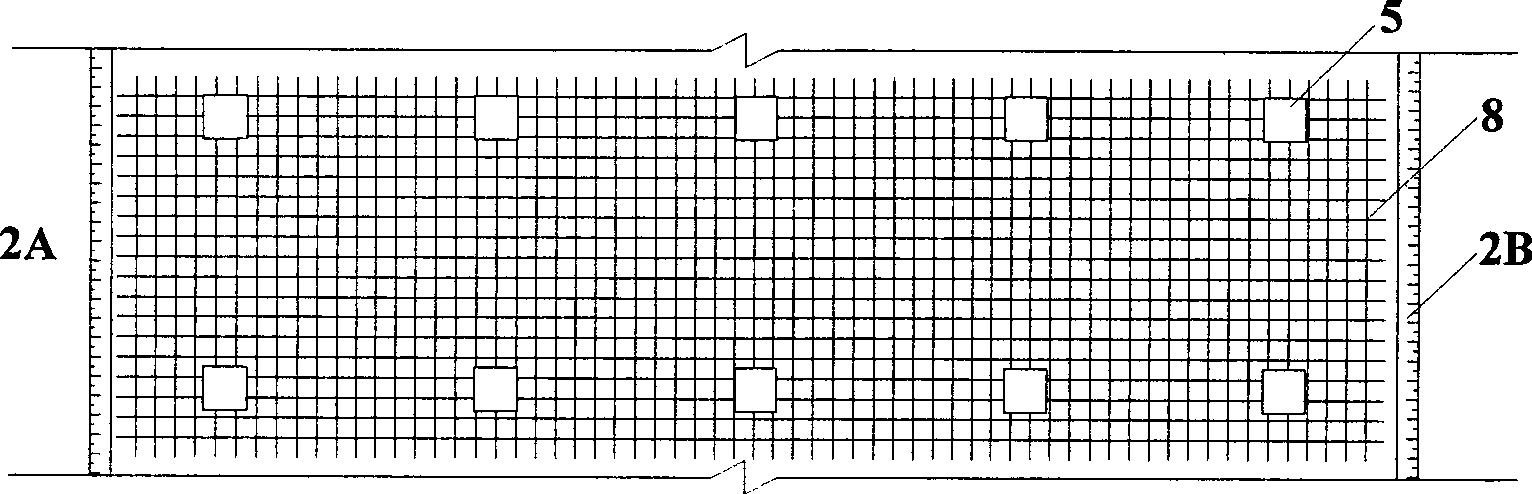

[0018] This processing method construction is simple, successively construction micropile 4, construction waste cushion layer 9, pile cap 5, lays steel-plastic geogrid 8, and construction lime soil layer 7 and the construction waste compacted soil layer 6 mixed with clay, The embankment 1 can be directly constructed.

[0019] The specific implementation steps are as follows:

[0020] ①Construction micro-pile 4

[0021] First excavate along the excavation line 12 on the original ground 3, the excavation depth is 35-45cm, and then arrange the pile positions on the excavation surface along the soft soil roadbed according to the design requirements, use a drilling rig to drill holes, and drill holes through the soft plastic Clay layer 13, the bottom of the hole enters the plastic or hard plastic clay layer 14 for about 2m, then fills the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com