High polymer material slurry filled discrete material pile composite foundation and construction method thereof

A technology of bulk material piles and composite foundations, which is applied in foundation structure engineering, soil protection, construction, etc., can solve the problems of insignificant penetration, etc., and achieve the effects of strong operability, energy saving, and improvement of pile side frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. The protection scope of the present invention is not limited only to the description of this embodiment. When the grouting slurry is replaced by ordinary Portland cement slurry, the method of the present invention is also applicable.

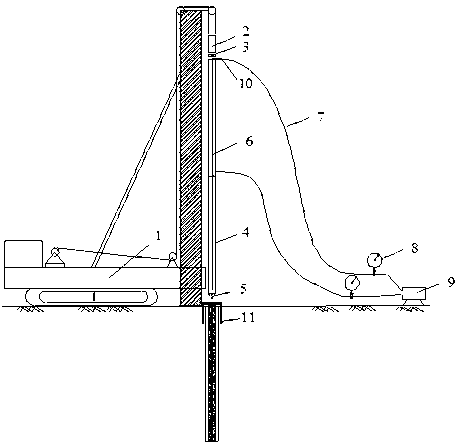

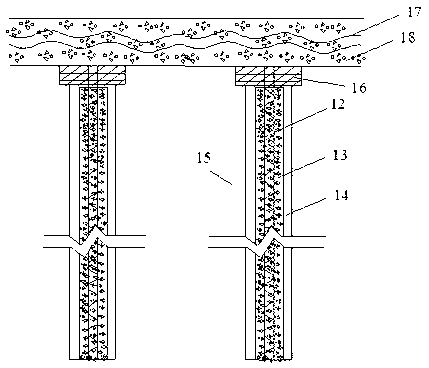

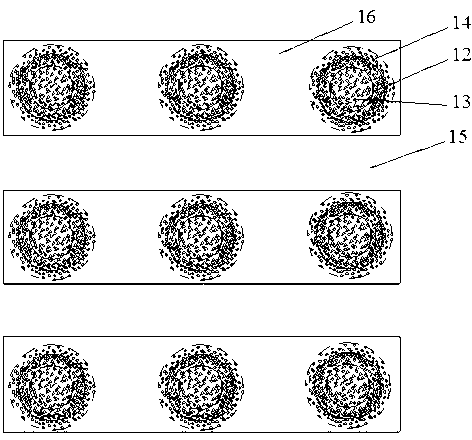

[0033] Such asfigure 1 and figure 2 As shown, firstly, an immersed tube 4 with a valve pile tip 5 is made, and a polymer material grouting system composed of a rigid grouting tube 6, a flexible grouting tube 7, a grouting pressure gauge 8 and a grouting pump 9 is made , the rigid grouting pipe 6 and the flexible grouting pipe 7 are connected through a joint 10; the flexible grouting pipe 7 is connected with the grouting pump 9 through a grouting pressure gauge 8; the rigid grouting pipe 6 passes through the reserved space on the top of the cylindrical cover plate 11 orifice. During implementation, level the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com