Steel hanging box system for underwater high-rise pile cap construction and construction technology thereof

A technology of high pile cap and steel hanging box, applied in caisson, infrastructure engineering, erection/assembly of bridges, etc., can solve the problems of wasting construction cost, delaying construction progress, etc., to reduce construction cost, speed up construction progress, save money effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Below in conjunction with the drawings and preferred embodiments, the steel hanging box system and construction technology for the construction of underwater high pile caps proposed according to the present invention are described in detail as follows.

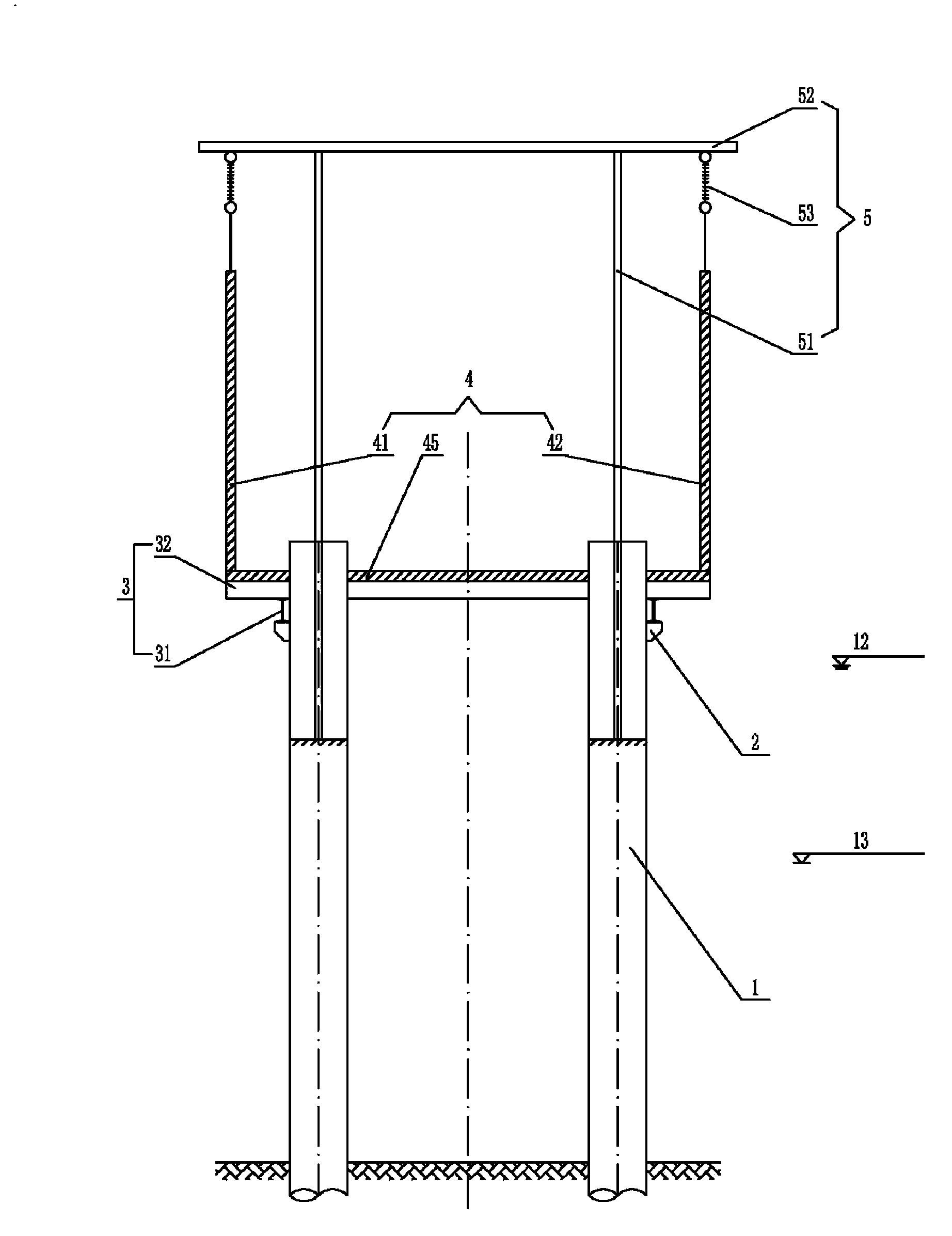

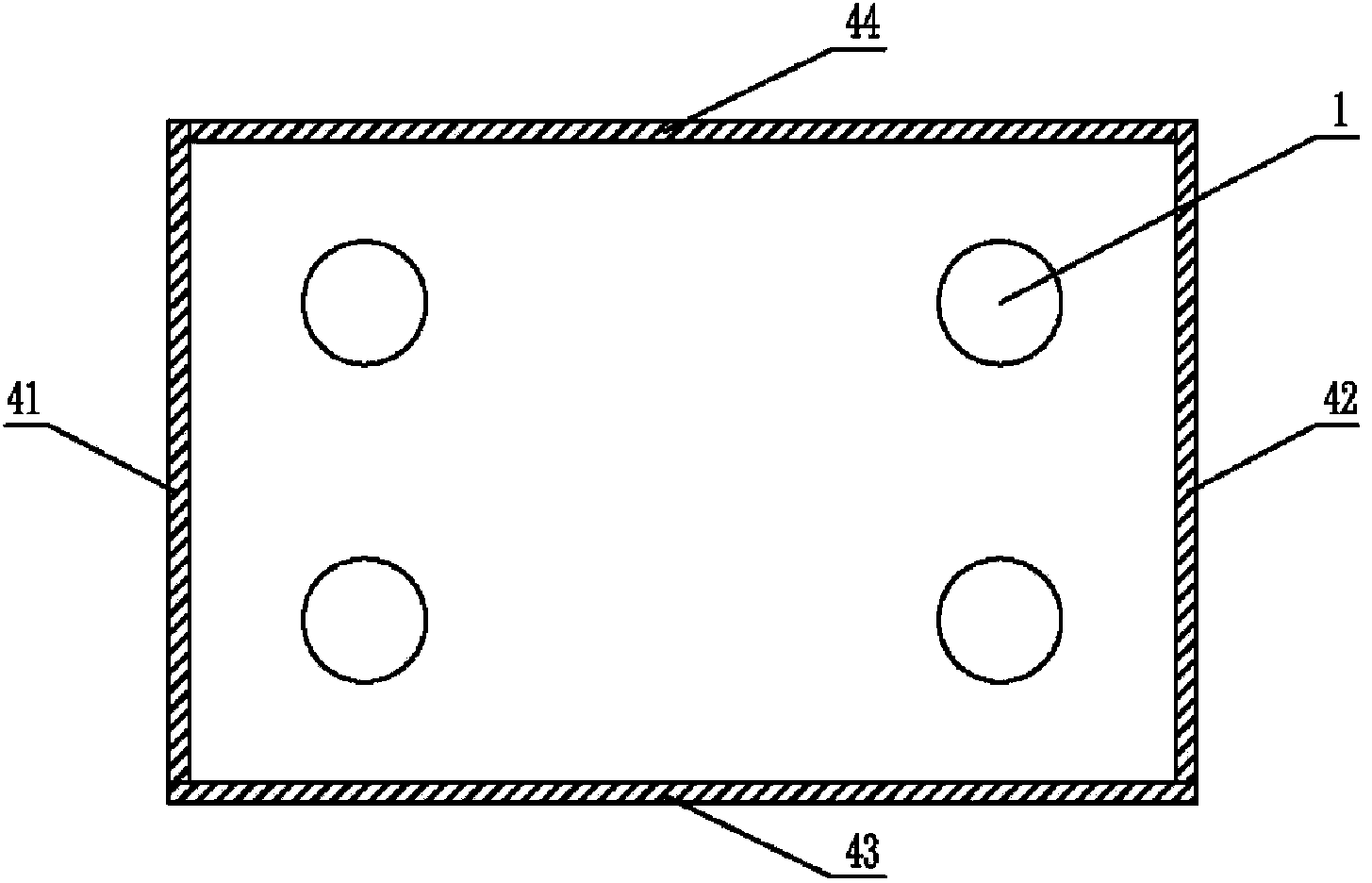

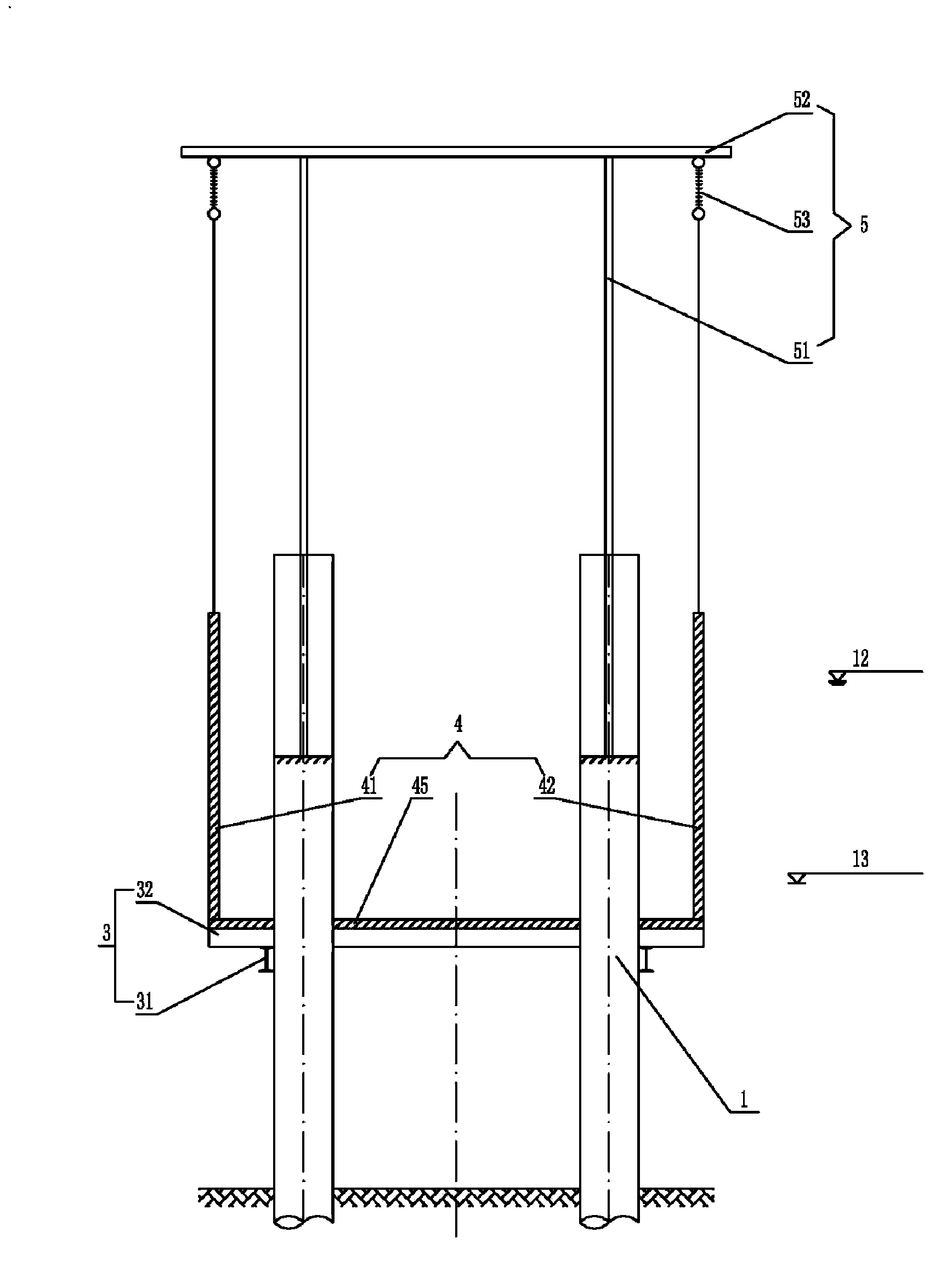

[0060] see figure 1 , figure 2 As shown, the steel hanging box system for the construction of underwater high pile caps when the preferred embodiment of the present invention is above the normal water level consists of corbels 2, stressed beams 3, steel hanging boxes 4, and suspension systems 5 composed of:

[0061] The corbel 2 has four corbels 2 in total. The four corbels 2 are respectively arranged on the outer edges of the four bored pile steel casings 1 along the bridge direction that are positioned above the normal water level 12.

[0062] The stressed beam 3 is composed of two stressed beams 31 and a plurality of secondary stressed distribution beams 32 . Wherein, one stressed beam 31 is arranged on two corb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com