Steel hoop truss type elevated pile cap tower crane foundation construction method and structure

A technology for high pile caps and tower crane foundations, which is applied in infrastructure engineering, construction, etc., can solve the problems of reducing the stability of tower crane foundations, increasing construction insecurity, and increasing the cost of tower crane foundation reinforcement, shortening the drying time, The construction is convenient and quick, and the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

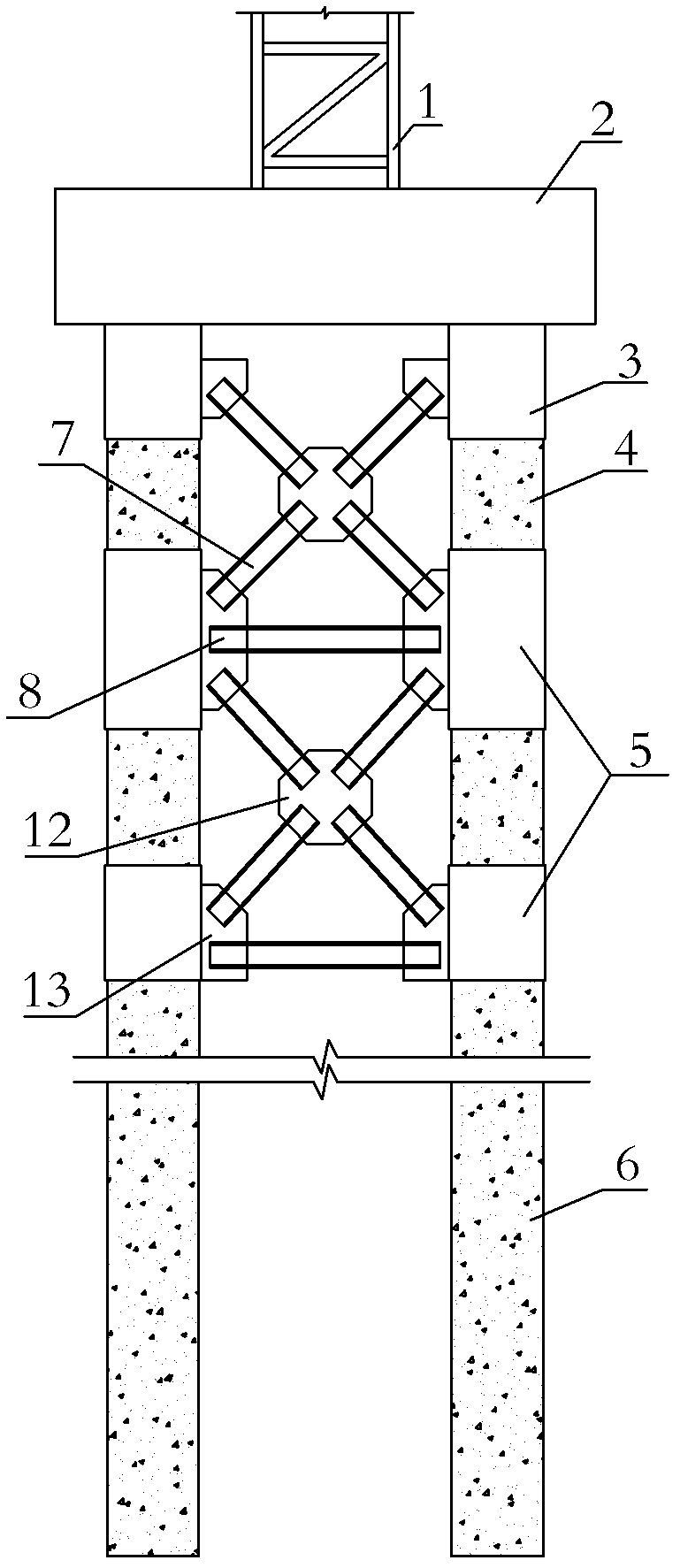

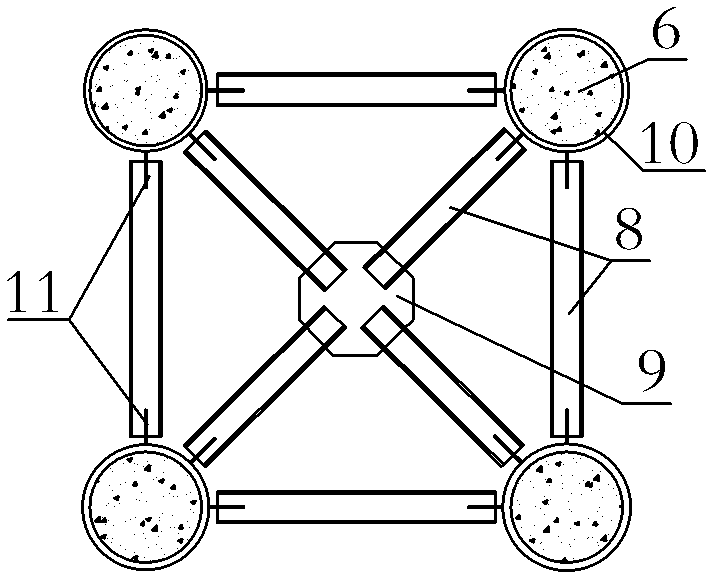

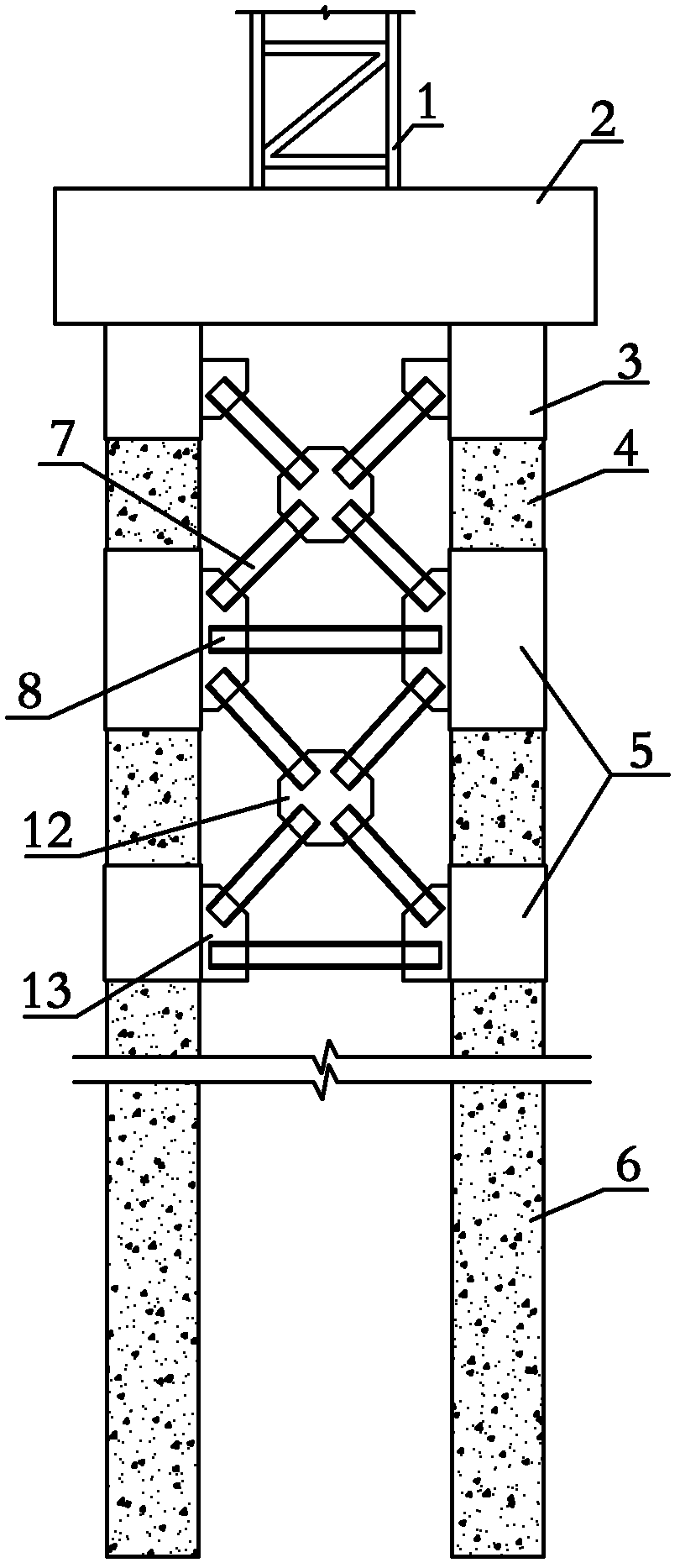

[0017] see Figure 1 ~ Figure 2 , a steel hoop truss type high pile cap tower crane foundation structure, including four concrete cast-in-situ piles arranged in the foundation pit, the pile top elevation is located on the ground surface, and each concrete cast-in-place pile is located in the embedding section 6 below the foundation pit bottom surface The ratio of the length to the length of the exposed section 4 in the foundation pit is greater than or equal to 1.5; the top of the four concrete pouring piles is poured with a reinforced concrete cap 2; the four concrete pouring piles are formed on the exposed section in the foundation pit to connect them A steel truss-type hoop structure together, the steel truss-type hoop structure includes N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com