Cable trench cover plate prying and transporting device

A cable trench cover and plug-in technology, which is applied to cable installation devices, cable installation, transportation and packaging, etc., can solve the problems of reducing the construction safety of construction personnel, increasing the labor intensity of construction personnel, and consuming physical strength of construction personnel. , to achieve the effect of improving construction safety, reducing labor intensity and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

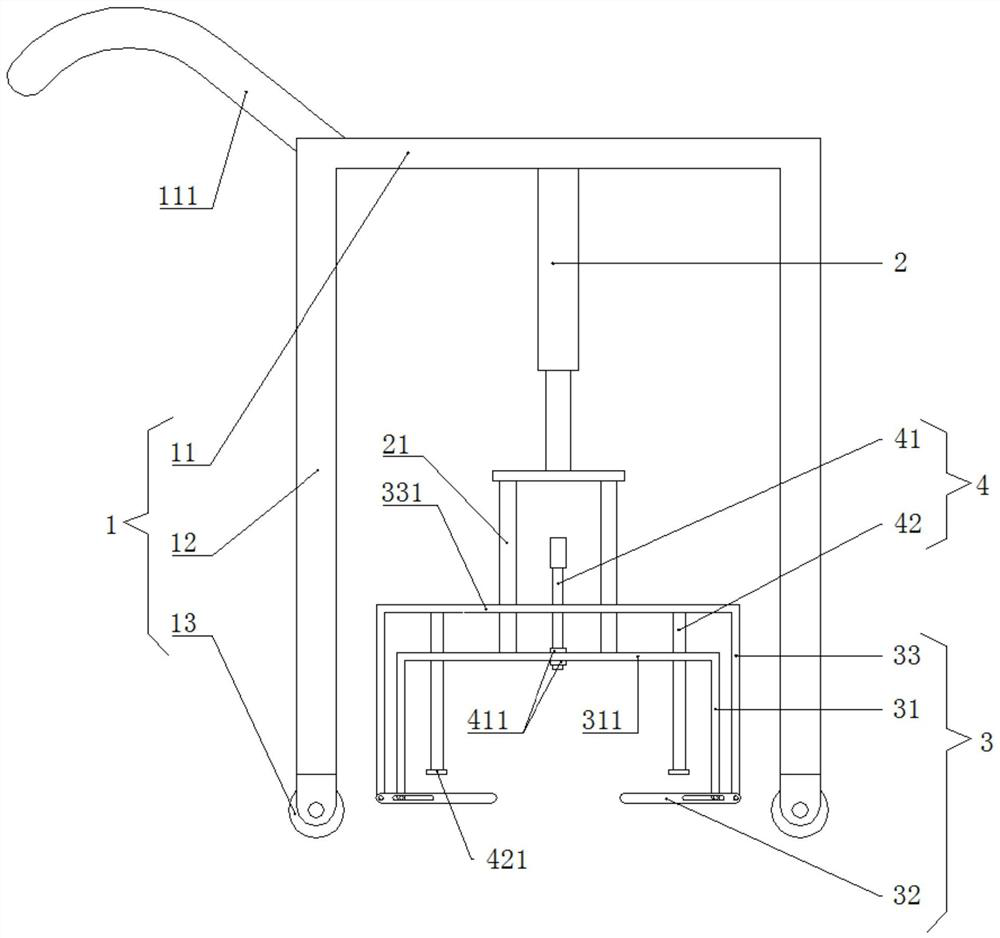

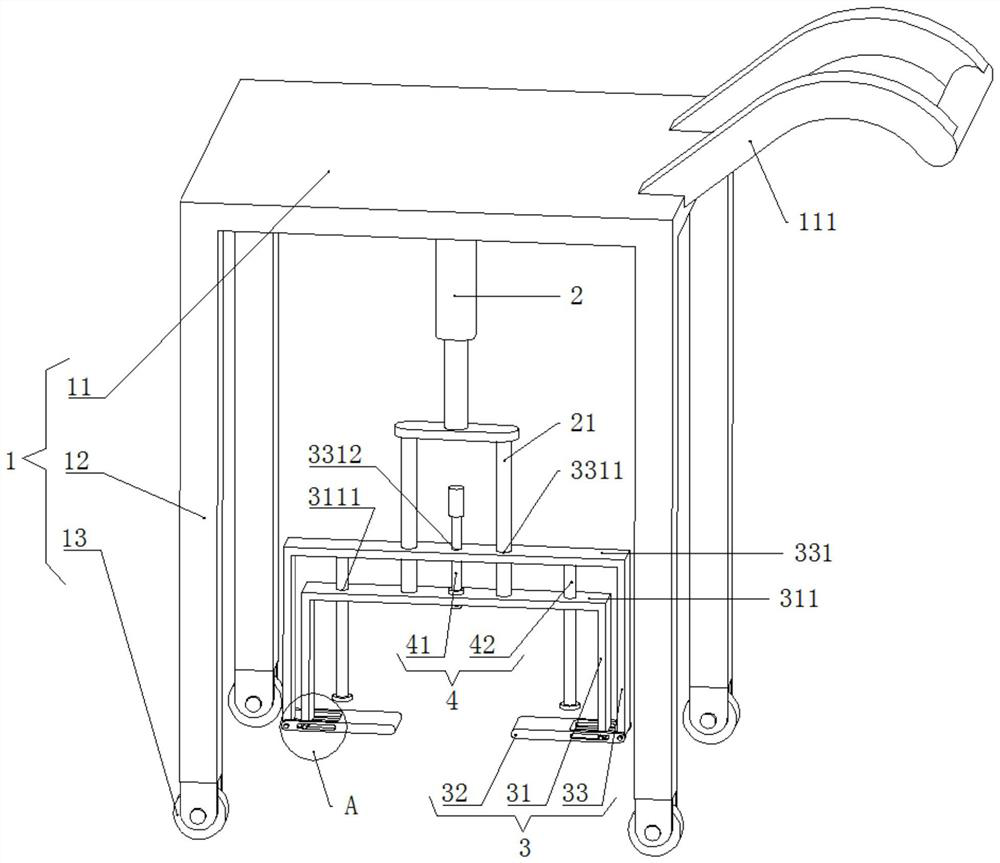

[0052] Such as Figure 1-3 As shown, a cable trench cover prying device includes a moving frame 1, a lifting member 2, and a prying mechanism 3.

[0053] The mobile frame 1 includes a mobile plate 11 , a mobile leg 12 , and a mobile wheel 13 arranged in sequence from top to bottom. There are four moving legs 12, the upper ends of the four moving legs 12 are welded with the moving plate 11, and the lower ends of the four moving legs 12 are equipped with moving wheels 13.

[0054] In order to facilitate construction personnel to move the mobile frame 1, one end of the mobile plate 11 is welded with a mobile handle 111 .

[0055] Lifting part 2 adopts electric push rod. The upper end of the electric push rod is welded and fixed with the moving plate 11.

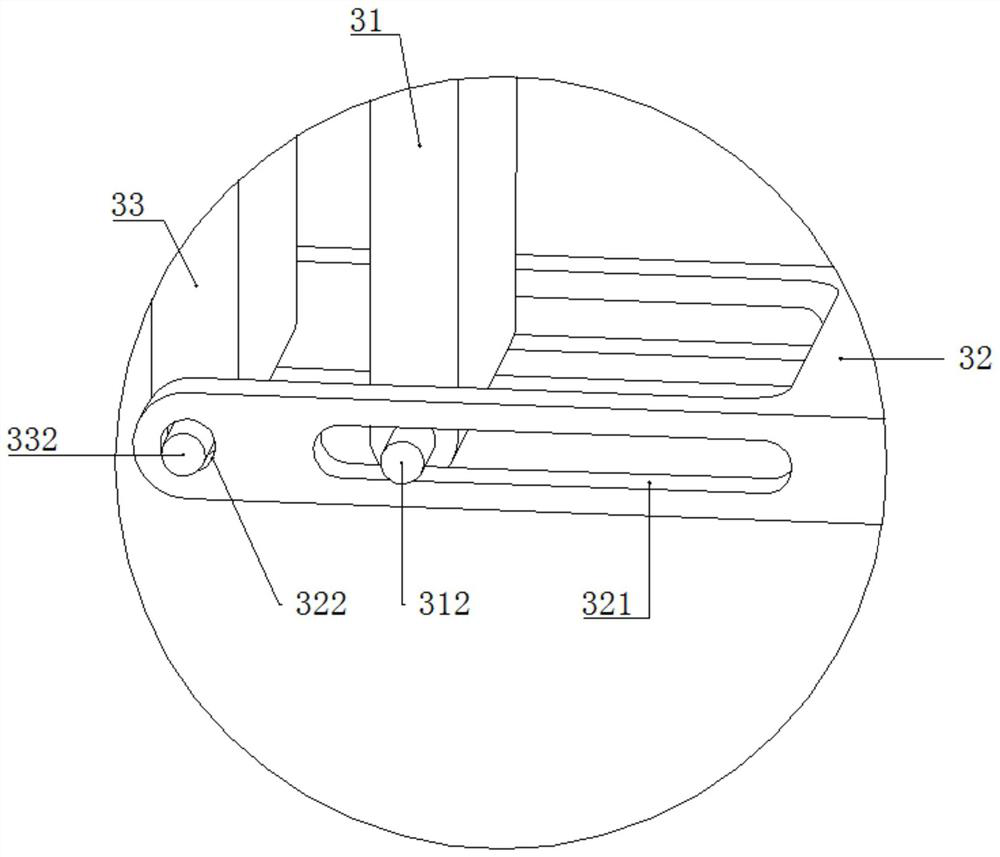

[0056] The prying mechanism 3 includes an inserting plate 31 , a rotating plate 32 and an adjusting plate 33 .

[0057] Two inserting plates 31 are arranged side by side, and a first connecting plate 311 is arranged between ...

Embodiment 2

[0083] Through the construction process of embodiment 1 "removing the cable trench cover 7 located on the cable trench", it can be seen that a kind of cable trench cover prying device in embodiment 1 can be moved back and forth between the cable trench and the open space. Take one cable trench cover plate 7, so when it is necessary to remove multiple cable trench cover plates 7, the user needs to push a kind of cable trench cover plate prying device in embodiment 1 to go back and forth between the cable trench and the open space Multiple trips. Thereby reducing the efficiency of removing a plurality of cable trench cover plates 7 from the cable trench.

[0084] In this regard, on the basis of Embodiment 1, this Embodiment 2 makes the following improvements:

[0085] Such as Figure 8-12 As shown, there are six moving legs 12, the upper ends of the six moving legs 12 are welded with the moving plate 11, and the lower ends of the six moving legs 12 are equipped with moving whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com